Fuzzy control method for high-frequency high-voltage power supply for electrostatic dust collection

A technology of high-frequency high-voltage power supply and fuzzy control, which is applied in the field of fuzzy control of high-frequency high-voltage power supply for electrostatic dust removal and high-frequency high-voltage power supply for electrostatic dust removal. , to achieve the effect of simple control and best spark control rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

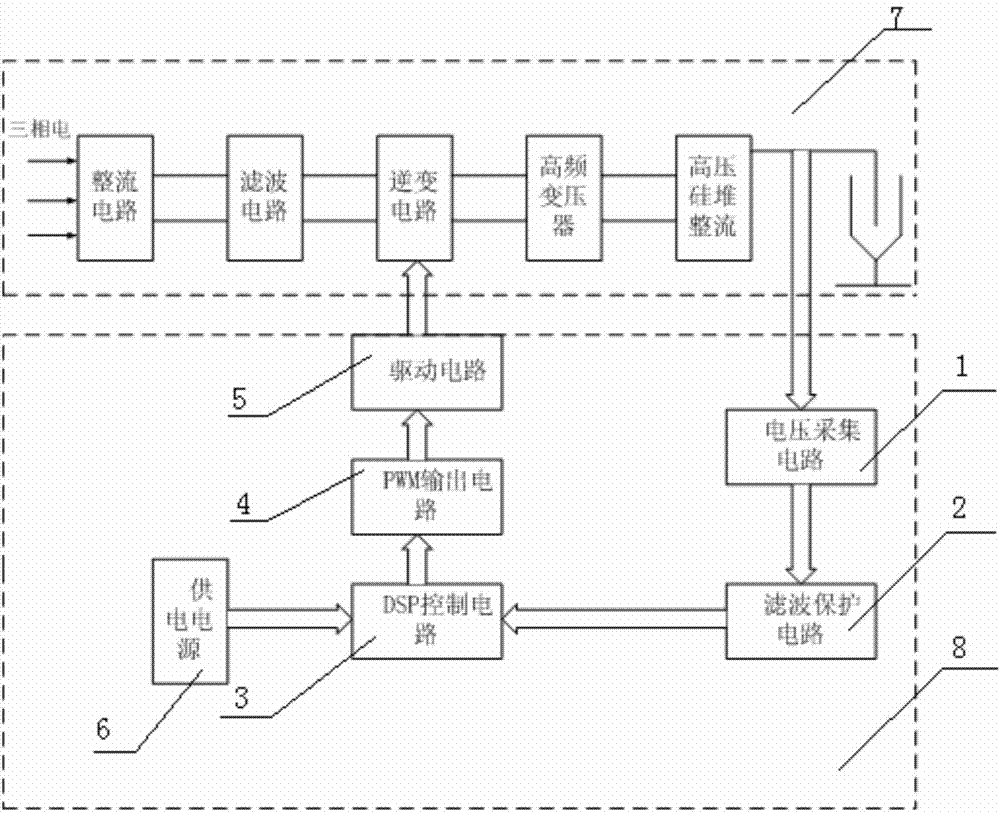

[0021] Such as figure 1 As shown, the dust collector includes the main circuit 7 of the high-frequency and high-voltage electrostatic dust removal power supply and the power supply controller 8. The voltage acquisition circuit 1 detects the output voltage of the dust removal power supply. After passing through the optocoupler isolation circuit in the circuit, the corresponding voltage signal is output to the filter protection. Circuit 2, filter protection circuit 2 sends the signal to the DSP control circuit 3 after processing, the A / D conversion circuit of the DSP chip converts the voltage signal into a digital quantity, and judges whether flashover occurs by comparing with the preset voltage quantity.

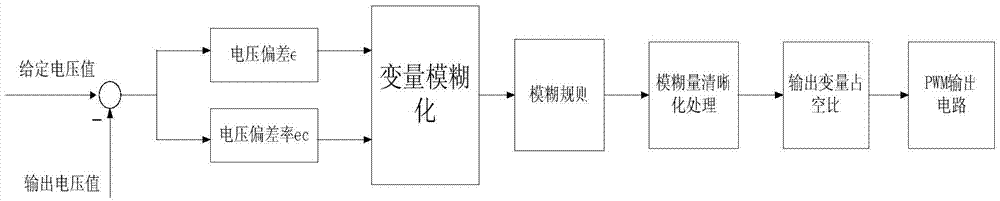

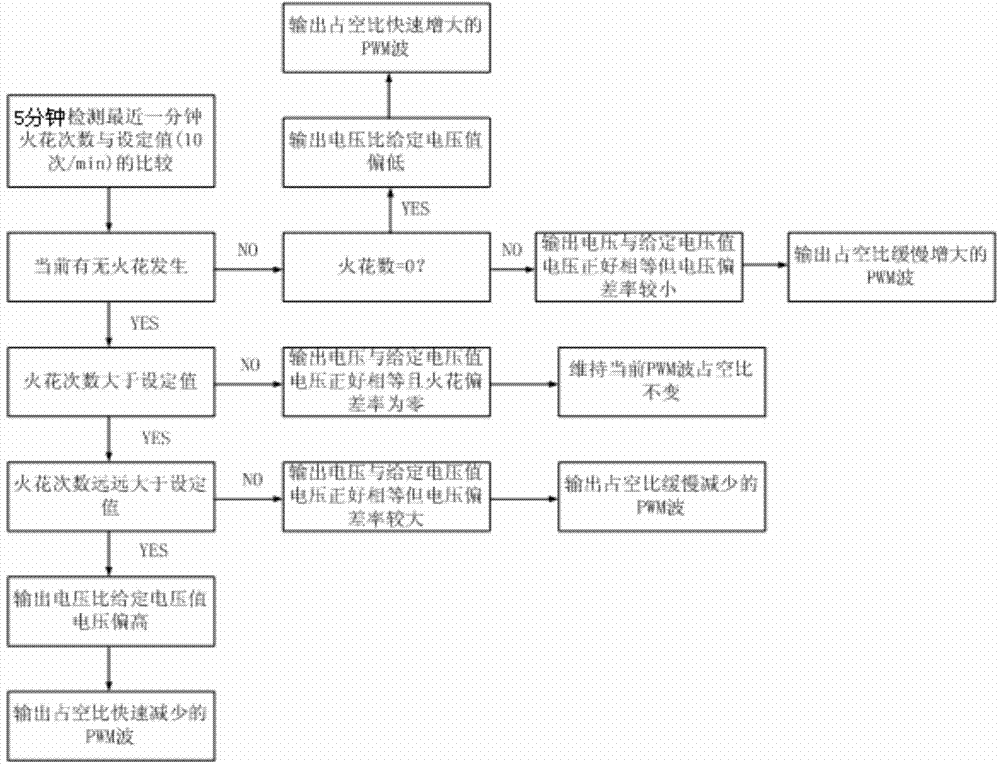

[0022] According to field experience, the optimal cremation rate is no more than 10 sparks per minute, and the voltage value at the optimal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com