Connecting rod bushing interference assembling method

An assembly method and connecting rod bushing technology, which are used in engine components, metal processing equipment, mechanical equipment, etc., can solve the problem that the engine connecting rod and bushing cannot meet the assembly requirements of large interference, and improve the one-time improvement. Success rate, uniform force, and the effect of reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Combine below Figure 2 to Figure 9 , the present invention is further described:

[0059] The basic process of powder forging of connecting rod includes the preparation of metal premixed powder, pressing and forming of pre-pressed parts, sintering of connecting rod pre-pressed parts at high temperature, closed-die forging at forging temperature, and finally shot blasting treatment, etc.

[0060] Specifically, the following steps are included:

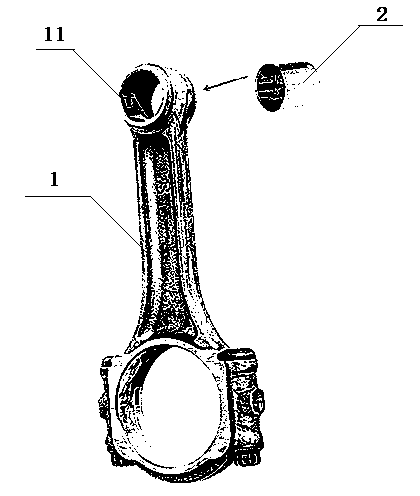

[0061] 1. Put the bushing 2 at room temperature (25°C) into the connecting rod small head hole 11 of the connecting rod preform under high heat (1100°C-1200°C, usually called hot forging temperature), and then heat Forging the connecting rod preload and the bushing 2 at the forging temperature (1100°C-1200°C).

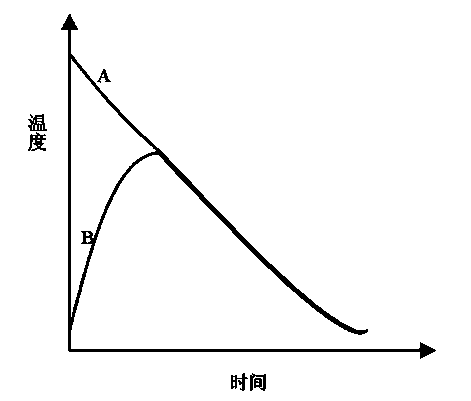

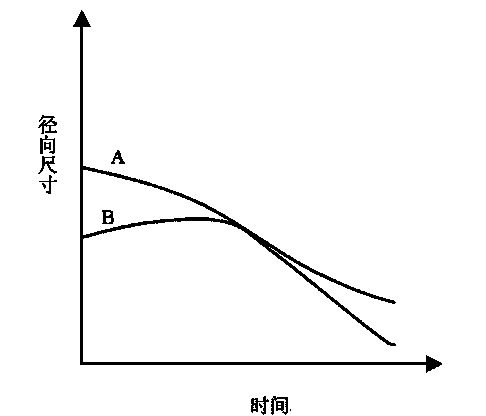

[0062] The forging principle is as follows: before the hot forging, the pre-pressed part of the connecting rod 11 is in a high-temperature state. At this time, after inserting the bushing 2 at room temperature, there w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com