A kind of grain distribution device for shallow round silo

A technology of distributor and round silo, applied in the field of grain feeding device, can solve problems such as automatic grading and crushing, and achieve the effects of shortening the falling distance, preventing the spread and reducing the falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

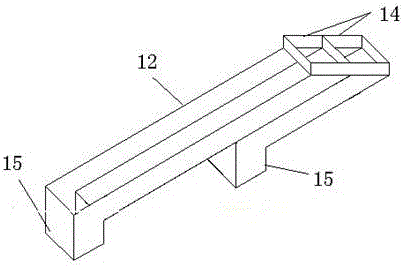

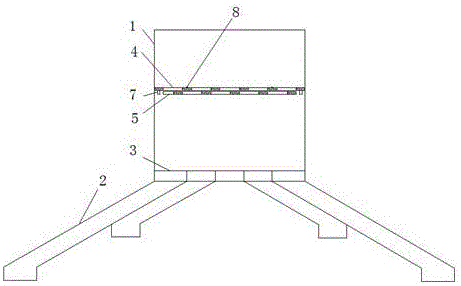

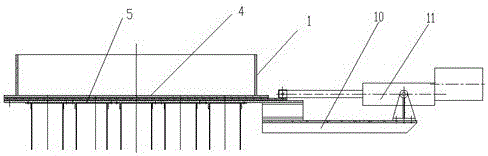

[0024] The present invention comprises a distributor 1 and a chute 2, the upper end of the distributor 1 is installed below the grain inlet, the chute 2 is installed at the lower end of the distributor 1, and the lower end of the chute 2 is respectively connected to the grain falling point 20 in the shallow round bin. Correspondingly, the grain falling points 20 in the shallow round bin are evenly distributed on the circumferential plane of the shallow round bin, and soybeans fall from the distributor 1 to the grain falling points 20 in the shallow round bin through the launder 2 .

[0025] As shown in the figure, the distributor 1 is a tank with a square upper and lower bottom surface. The bottom of the distributor 1 is divided into a plurality of square orifices 3 of the same area by steel plates. Each orifice 3 is connected to the upper end of a launder 2. The upper sieve plate 4 and the lower sieve plate 5 placed horizontally are installed in the inner cavity of the distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com