A method for preparing vanadium dioxide by dual temperature zone reduction method

A technology of vanadium dioxide and reduction method, which is applied in the direction of vanadium oxide, etc., can solve the problems of cumbersome preparation process, difficulty in controlling the stoichiometric ratio of vanadium dioxide powder, and limited preparation amount, so as to facilitate the collection of samples, crystal phases and particles The effect of controllable diameter and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

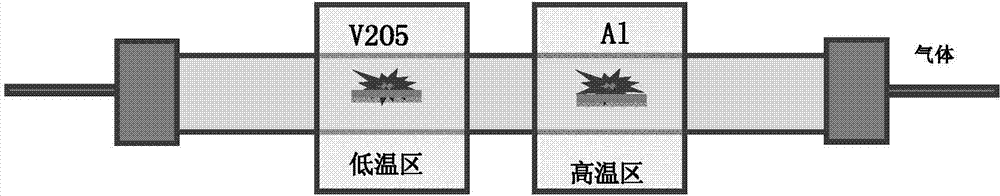

[0032]Commercial vanadium pentoxide is used as raw material, and aluminum is a highly active reducing metal. They are placed in different heating zones in a closed tube furnace. After the whole system is evacuated to 0.1Pa, the aluminum and vanadium pentoxide are heated to 800 °C and 400 °C, turn off the heating power after 3 hours of reaction. After the sample is cooled, vanadium dioxide is obtained.

Embodiment 2

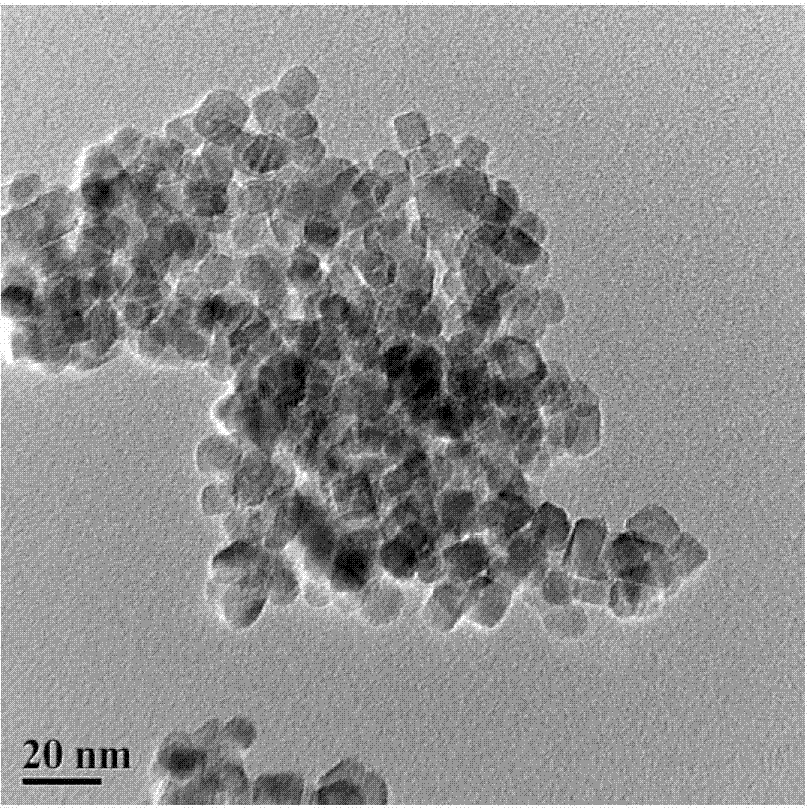

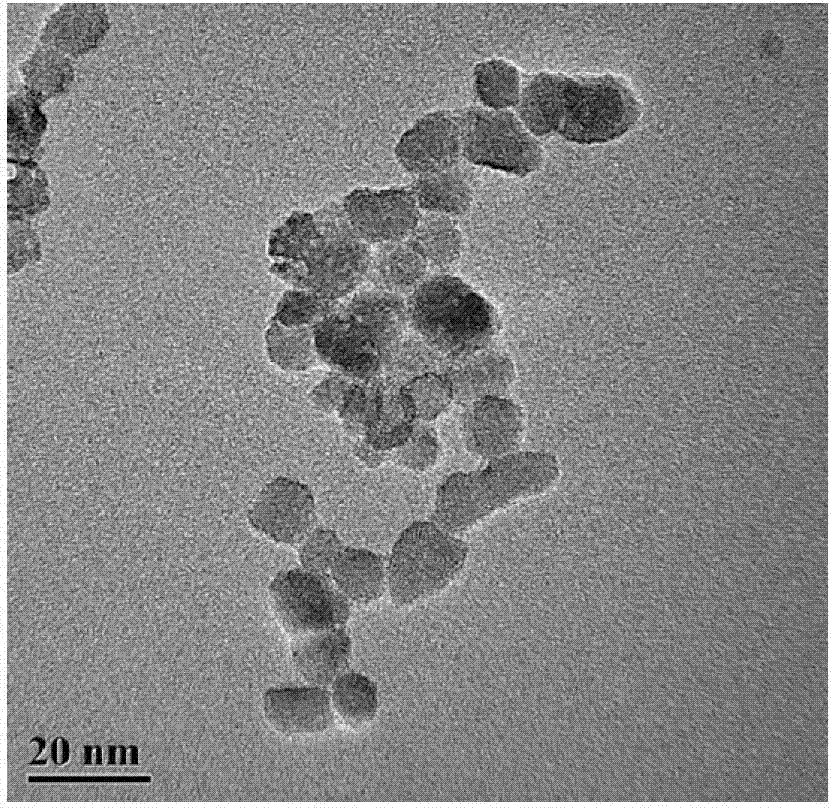

[0034] Using self-made vanadium pentoxide nanopowder as raw material (Ding SJ, Liu ZQ, Li DZ, Zhao W, Huang FQ, ACS Applied Materials & Interfaces. 2013, 5, 1630–1635), aluminum is a highly active reducing metal, put Put them into different heating zones in a closed tube furnace, vacuumize the whole system to 0.1Pa, heat the aluminum and vanadium pentoxide to 850°C and 200°C respectively, and turn off the heating power after 6 hours of reaction. After the sample is cooled, vanadium dioxide nanopowder is obtained. figure 2 and image 3 The TEM images of the vanadium pentoxide powder as the raw material and the vanadium dioxide powder obtained are shown respectively. It can be seen from the figure that the morphology of the vanadium dioxide powder can be kept consistent with the precursor vanadium pentoxide powder or Close, its particle size is 10-20nm.

Embodiment 3

[0036] Commercial vanadium pentoxide is used as raw material, and magnesium is a highly active reducing metal. They are placed in different heating zones in a closed tube furnace. After the whole system is evacuated to 0.1Pa, aluminum and vanadium pentoxide are heated to 750 °C and 450 °C, turn off the heating power after 5 hours of reaction. After the sample is cooled, vanadium dioxide is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com