Internal combustion engine cooling oil

A cooling oil and internal combustion engine technology, applied in the field of internal combustion engine cooling oil, can solve the problems affecting the viscosity of the engine oil, the damage of the internal combustion engine, and the effect of sealing and lubrication, and achieve the effects of preventing metal corrosion, not being prone to high pressure, and preventing the generation of air chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

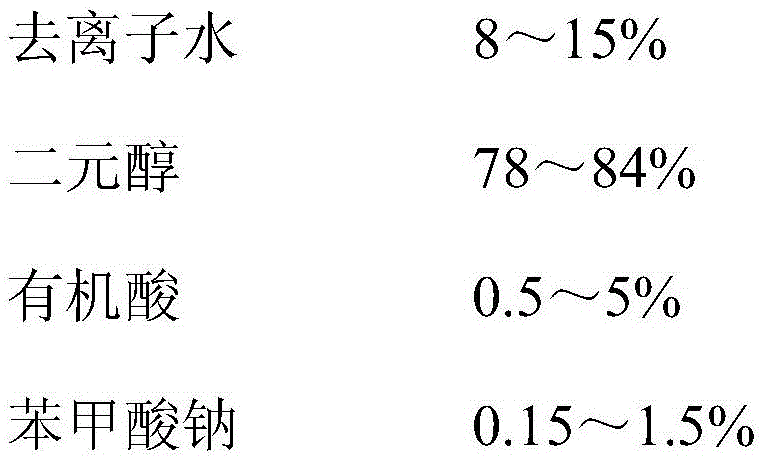

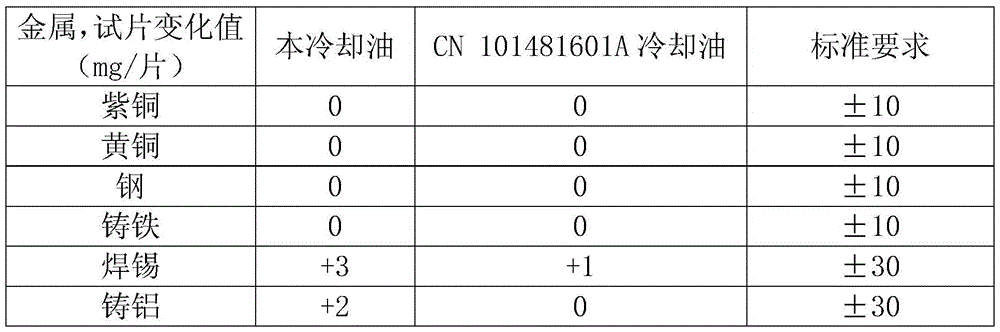

[0017] 1. Take 8 parts of deionized water, 60 parts of ethylene glycol, and 24 parts of 1,4-butanediol, put them into the reaction kettle, stir and heat up to 80°C, then add 1 part of octanoic acid, 3 parts of azelaic acid, and sodium benzoate 1 part, 3 parts sodium hydroxide, heat at 90°C for 40 minutes and then cool to obtain clear, transparent cooling oil with pH 8.4; conduct freezing point and boiling point determination experiments according to SH / T0090-1991 and SH / T0089-1991, and the results are based on The cooling oil has a freezing point of -45°C and a boiling point of 124°C.

[0018] 2. Take 15 parts of deionized water, 70 parts of ethylene glycol, and 8 parts of propylene glycol, put them into the reaction kettle, stir and heat up to 90°C, then add 0.6 parts of octanoic acid, 3.4 parts of sebacic acid, 1 part of sodium benzoate, and sodium hydroxide 2 parts, heat at 100°C for half an hour and cool to obtain a clear, transparent cooling oil with pH 7.8; according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com