Differential magnetic suspension vibration isolator

A magnetic levitation and vibration isolator technology, which is applied in the direction of magnetic spring, spring/shock absorber, non-rotational vibration suppression, etc., can solve the problems of small active control force, difficult control, large nonlinearity, etc., and achieve good vibration isolation Effect, good application prospect, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiments and drawings, but it is not limited to the content described below.

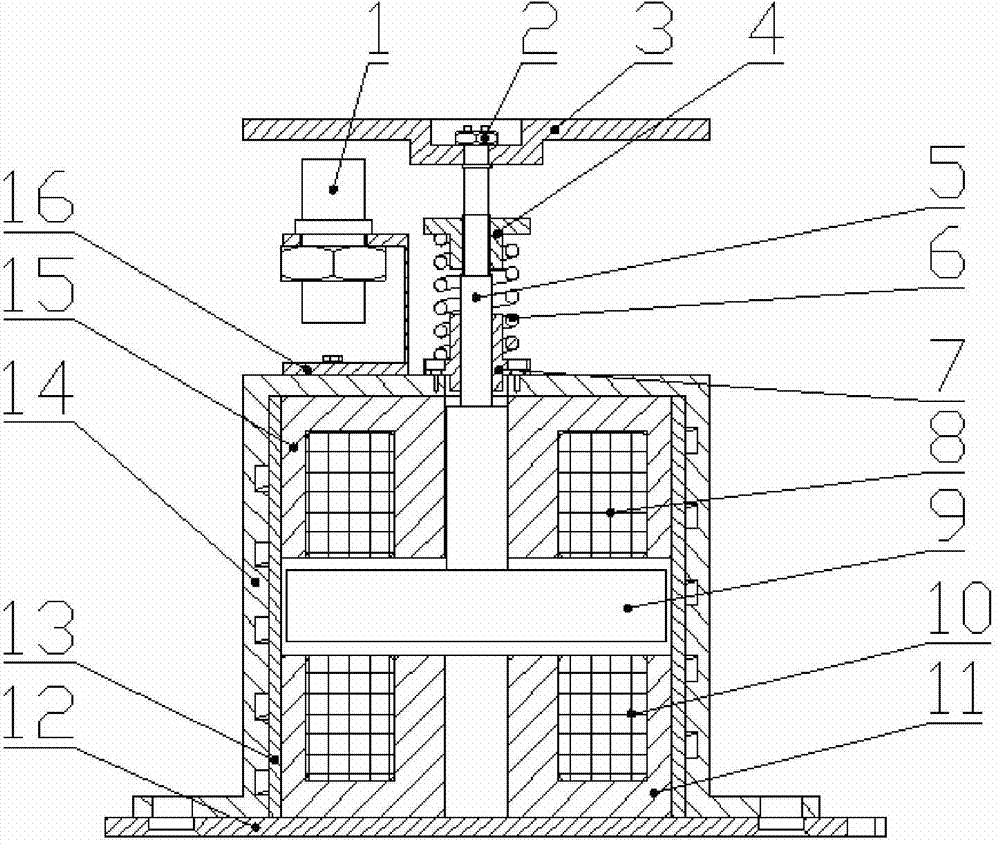

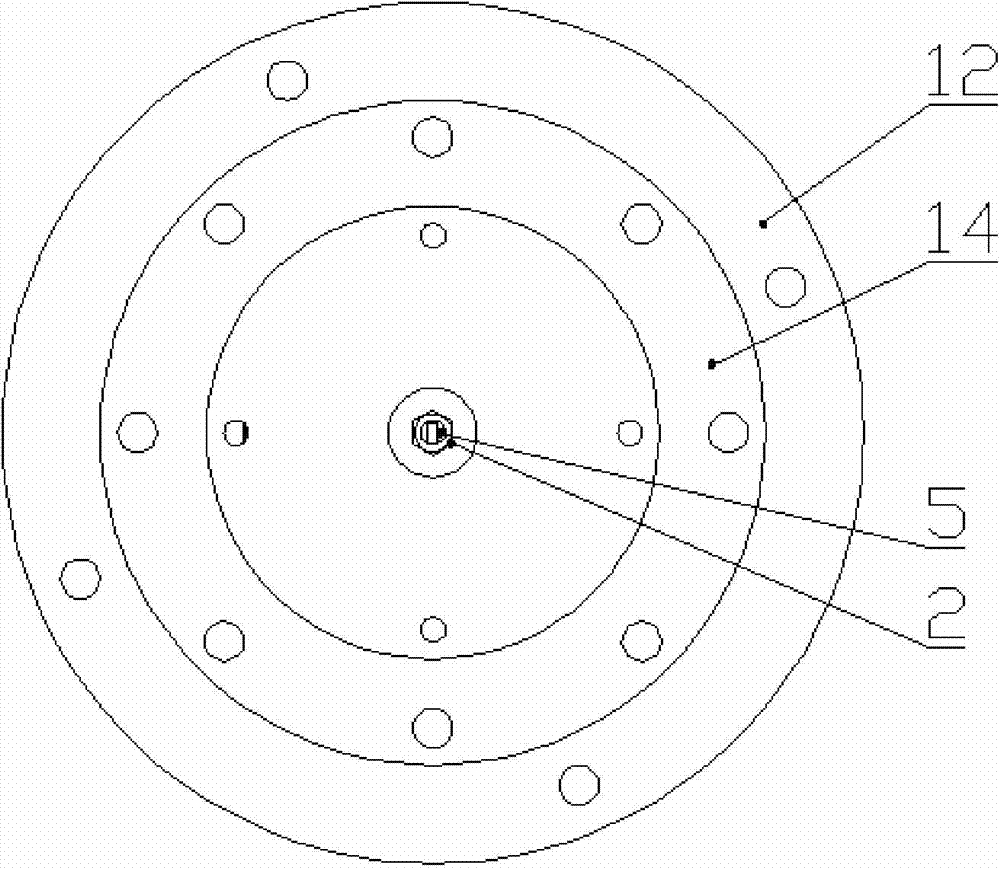

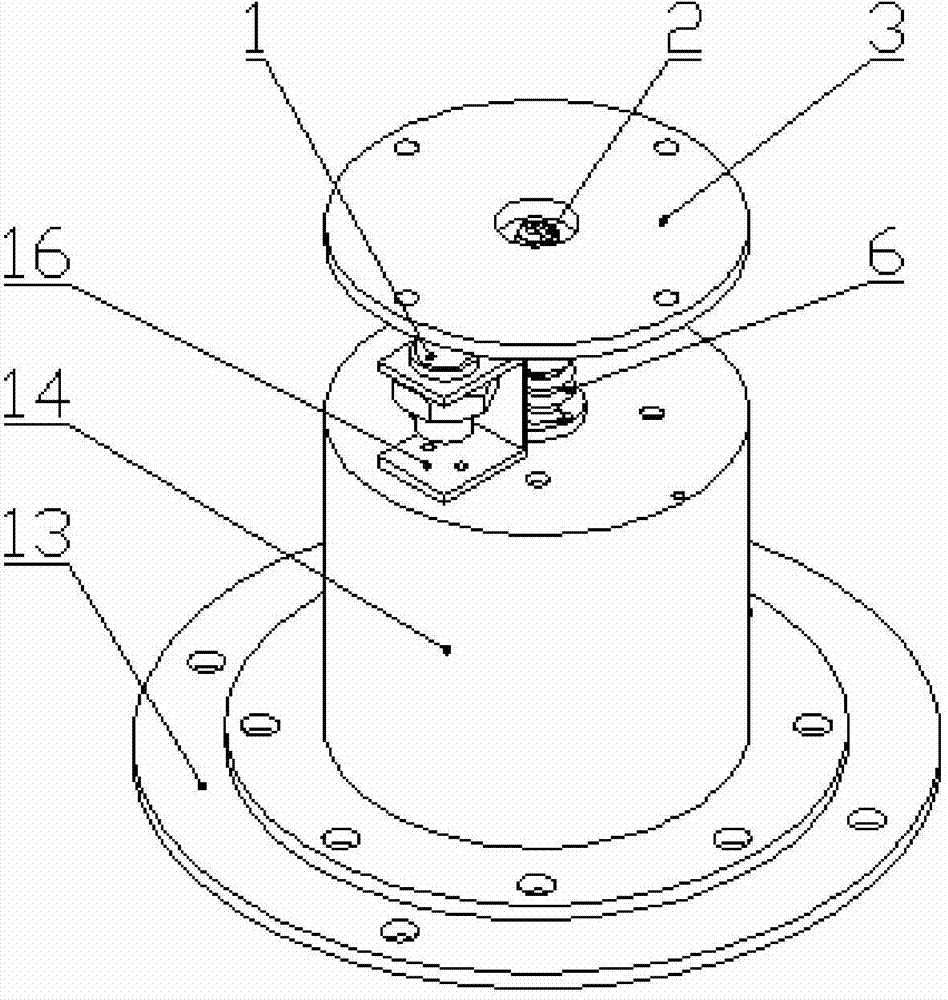

[0035] The differential magnetic suspension vibration isolator provided by the present invention has a structure such as Figure 1 to Figure 3 As shown, it includes: an upper ring-shaped E-shaped electromagnet 15 and a lower ring-shaped E-shaped electromagnet 11 respectively fixed on the housing 14 and a base 12, and the upper ring-shaped E-shaped electromagnet 15 and the lower ring-shaped E-shaped The upper coil winding 8 and the lower coil winding 10 in the slot of the electromagnet 11, and the armature 9 fixed to the connecting flange 3 by the connecting rod 5. The armature 9 is located between the upper ring-shaped E-shaped electromagnet 15 and the lower ring-shaped E-shaped electromagnet 11 and is supported by the spring 6 and the adjusting nut 4. The casing 14 is fixed on the base 12, and the inner fixing is matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com