Thermal conductivity and thermal diffusivity sensor based on MEMS double heater

A technology of thermal diffusivity and heaters, which is applied in the direction of instruments, scientific instruments, and thermal development of materials, etc., can solve the problems of increasing measurement errors, and achieve the effects of reducing requirements, reducing influence, and small temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

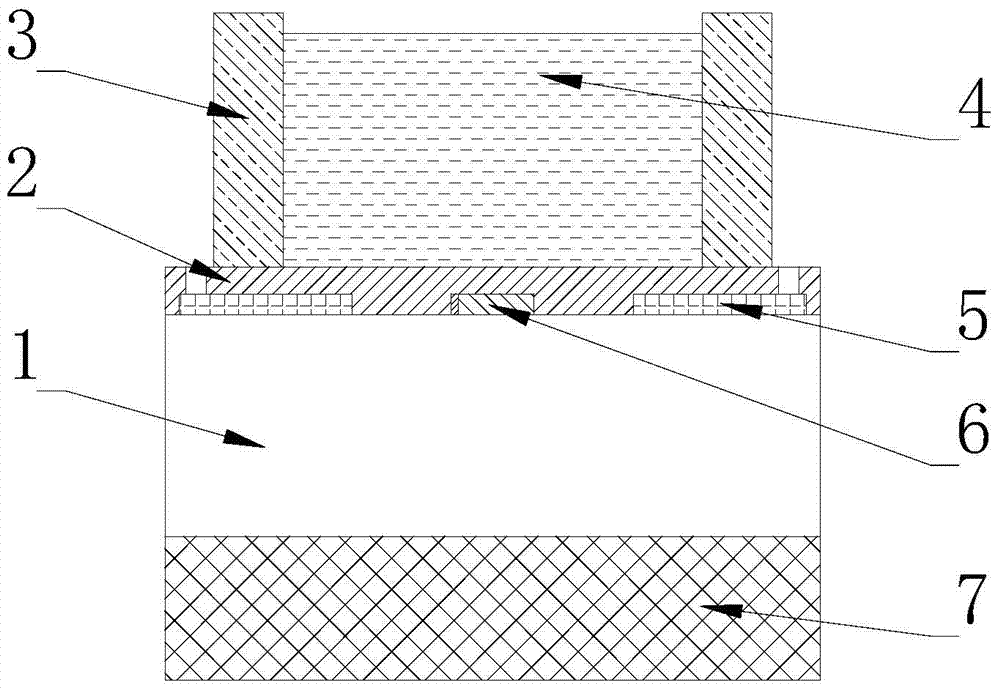

[0029] refer to figure 1 , a thermal conductivity and thermal diffusivity sensor based on MEMS dual heaters, comprising a substrate 1, a heater 6 arranged in the center of the upper surface of the substrate 1, a pad 5 positioned next to the heater 6 on the upper surface of the substrate 1, and heating The device 6 is connected, the insulating layer film 2 is covered on the heater 6, the pad 5 and the substrate 1, the insulating layer film 2 is provided with a cavity wall 3, and the cavity wall 3 and the insulating layer film 2 form a cavity structure in which the The liquid 4 is measured, the heater 6 is used as a temperature sensor at the same time, and the copper block 7 is pasted on the lower surface of the substrate 1 as a heat sink.

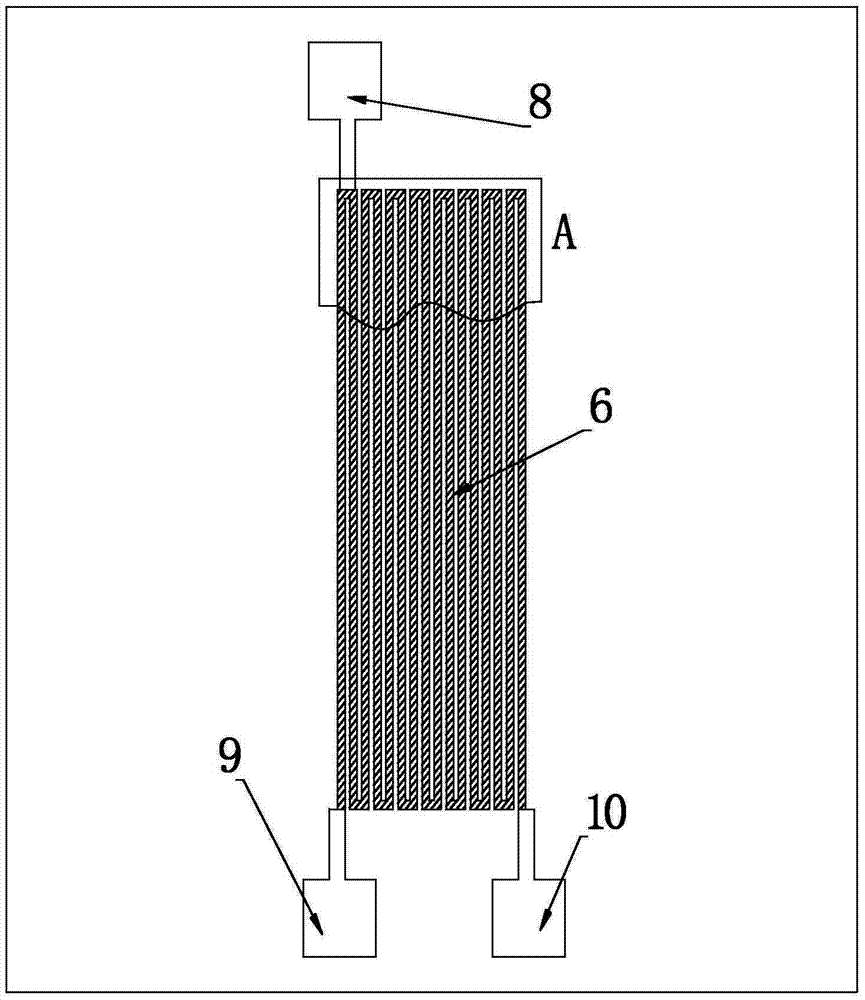

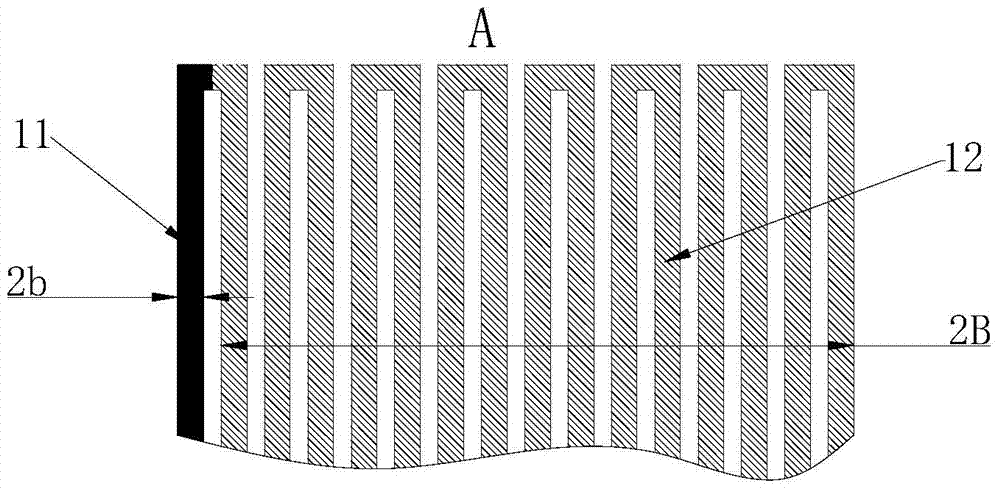

[0030] Such as Figure 2-a and 2-b As shown, the heater 6 is a metal strip with a multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com