Electromagnet

An electromagnet and armature technology, applied in the field of electromagnets, can solve the problems of low bearing pressure in the inner cavity of the magnetic core tube, low performance suction power, high suction power and high power, etc., and achieves simple and effective structure, reduced gap, and pressure bearing capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

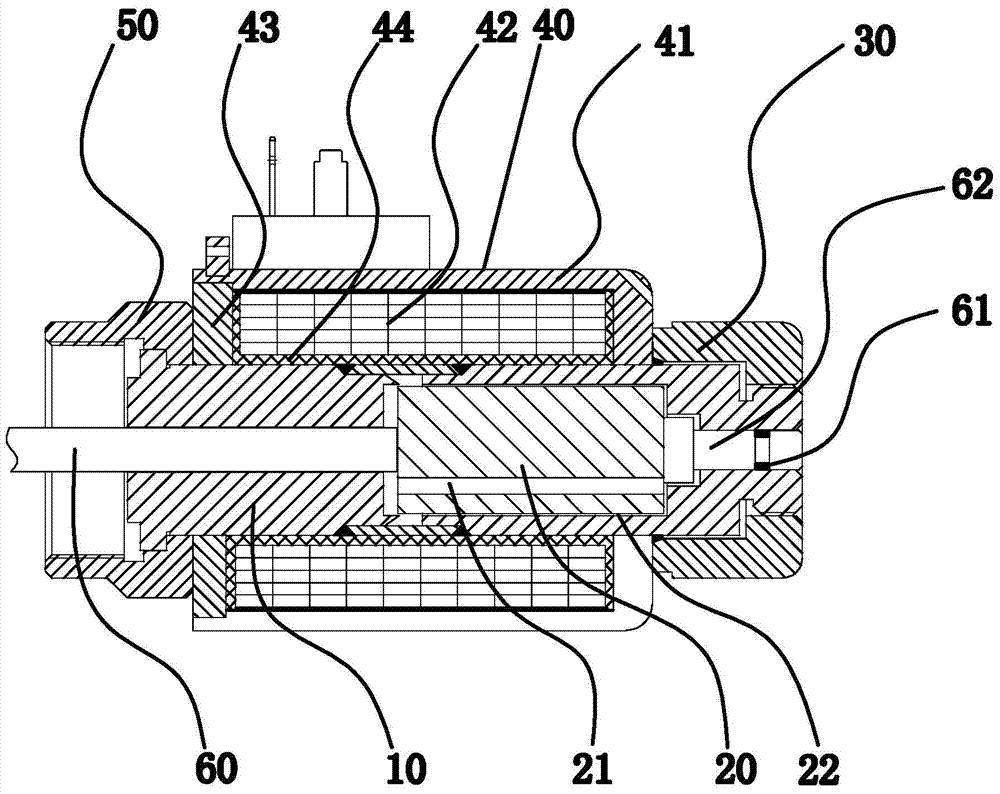

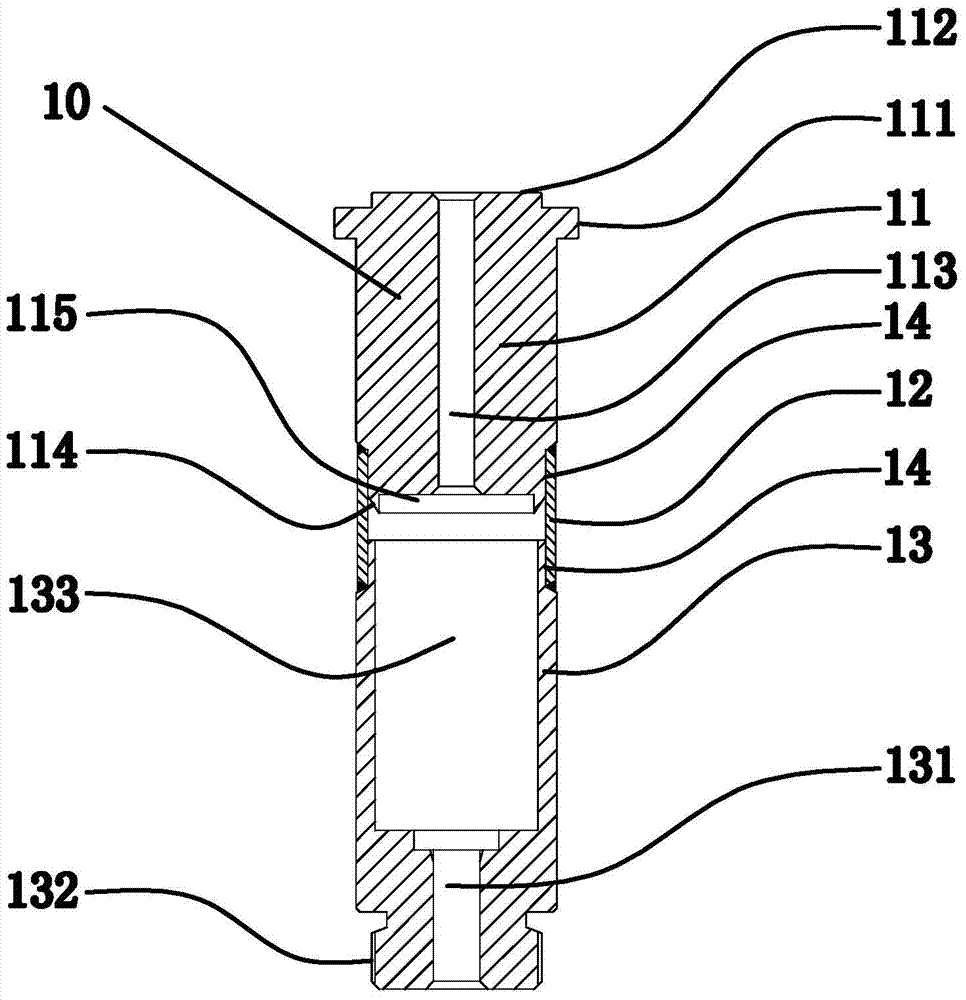

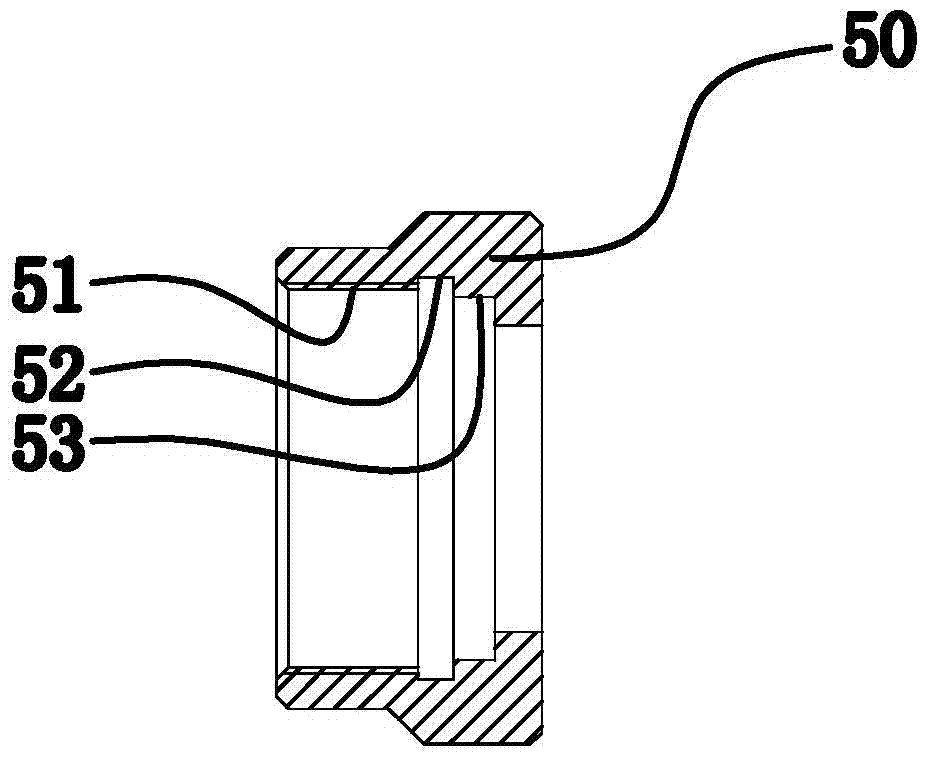

[0034] like figure 1 and figure 2 As shown, the present invention includes a coil assembly 40, a magnetic core tube 10, and an armature 20 arranged in the magnetic core tube 10. The coil assembly 40 includes a cylindrical yoke 41, a skeleton 44 installed in the yoke 41, and a The coil 42 on the skeleton 44 is filled with epoxy resin between the coil 42 and the yoke 41. The open end of the yoke 41 is sealed with a yoke piece 43. The magnetic core tube 10 includes a guide sleeve 13 and an iron core 11. The guide sleeve 13 and the iron core 11 are firmly connected and sealed with a steel ring 12. The magnetic core tube 10 runs through the yoke piece 43, the skeleton 44 and the magnetic yoke 41 in turn. One end of the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com