Centralized-control type LED (Light Emitting Diode) headlamp set dimming system

A LED lamp group and centralized control technology, applied in the direction of light source, electric light source, energy-saving control technology, etc., can solve the problems of complex design, short service life, high energy consumption, etc., to achieve convenient adjustment, reduce use cost, and light energy utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

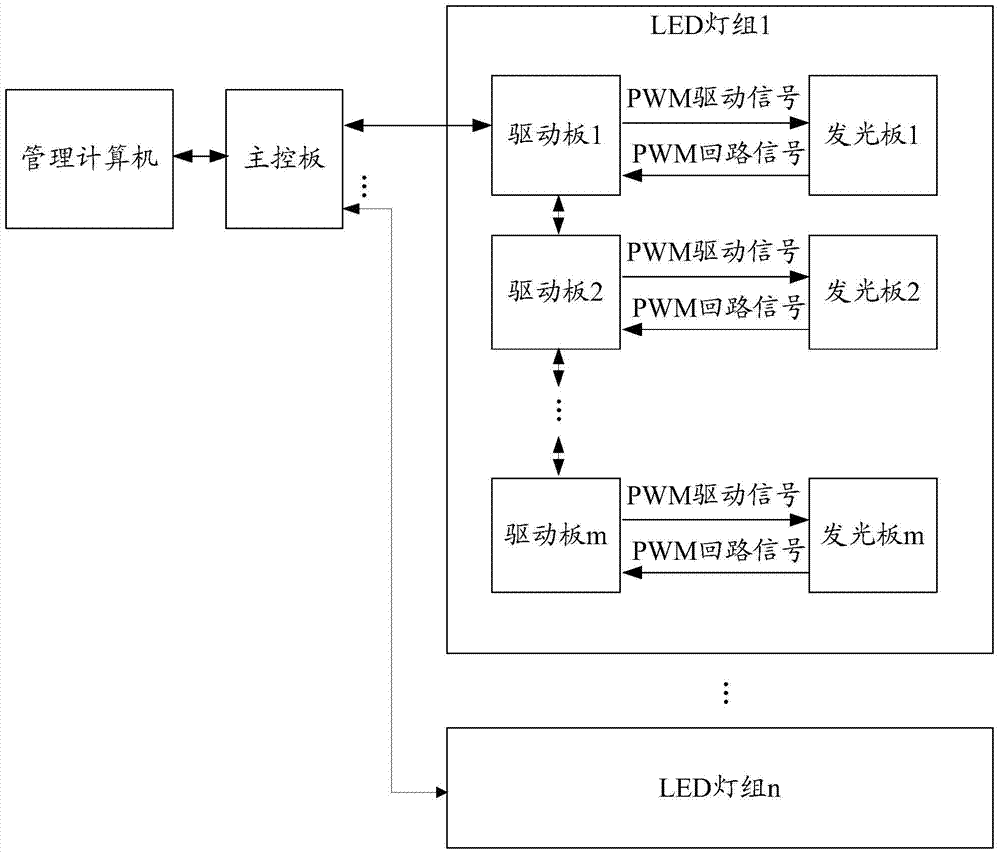

[0029] A centralized control type LED light group dimming system according to an embodiment of the present invention, such as figure 1 As shown, it includes the following components: management computer, main control board and n LED light groups, wherein the LED light group includes: m driving boards and m light-emitting boards connected to them correspondingly, m, n≥1, m and The number of n can be flexibly set as required.

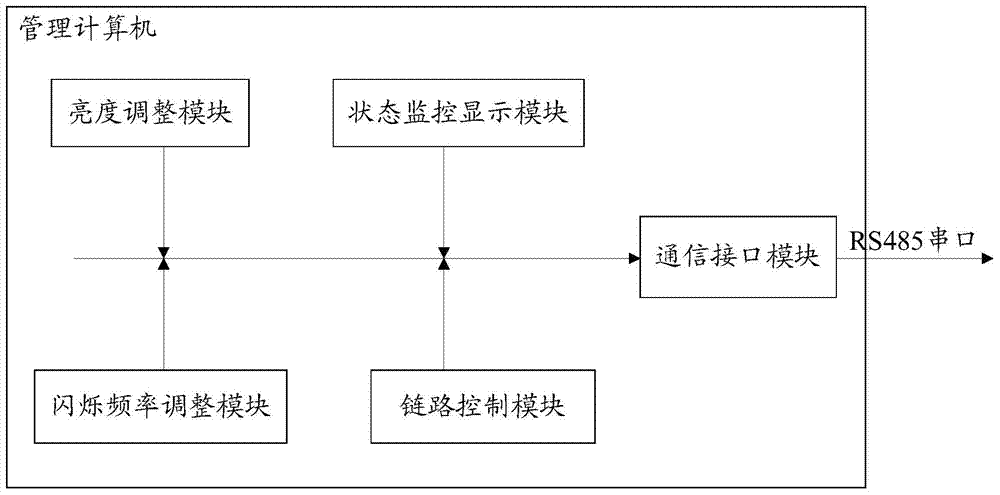

[0030] figure 2 It is a schematic diagram of the specific composition of the management computer, such as figure 2 As shown, the management computer includes: a brightness adjustment module, a flicker frequency adjustment module, a link control module, a status monitoring display module and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com