Method for recycling water from wet desulphurization flue gas and device thereof

A wet desulfurization and flue gas technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of large water consumption and application restrictions in water-scarce areas, and achieve economic cost reduction, energy saving and environmental protection. , the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for recovering water in wet desulfurization flue gas of the present invention comprises the following steps:

[0021] (1) Cool down the original flue gas before wet desulfurization;

[0022] (2) cooling the circulating spray water used in the wet desulfurization treatment flue gas;

[0023] (3) Heating the clean flue gas.

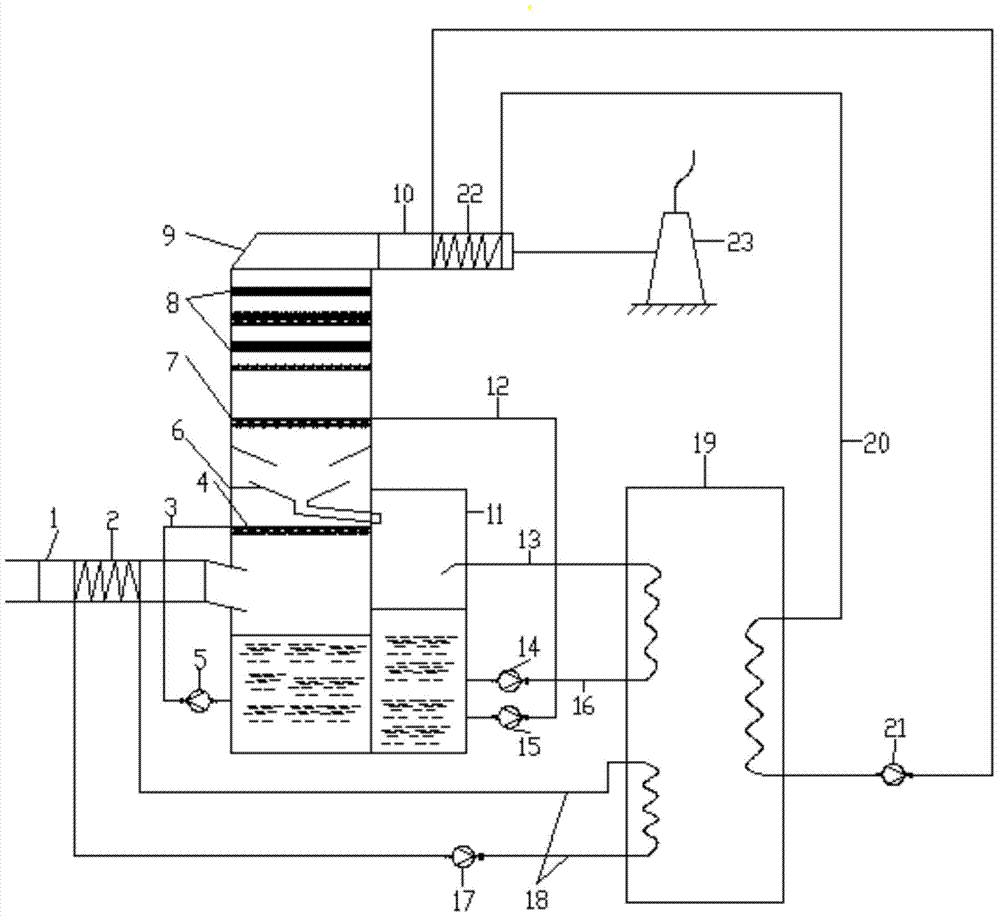

[0024] For the above-mentioned method for recovering water in wet desulfurization flue gas, it can be carried out by the following device, such as figure 1 As shown, a device for recovering water in wet desulfurization flue gas includes a connected original flue 1, a wet desulfurization device and a clean flue 10, and also includes a connected raw flue gas cooling device, spraying Water cooling device and clean flue gas heating device, wherein, the original flue gas cooling device is connected to the original flue, and the spray water cooling device is connected to the wet desulfurization device.

[0025] In the above embodiments, the cle...

Embodiment 2

[0029] Such as figure 1 As shown, a method and device for recovering water in wet desulfurization flue gas of the present invention, its basic implementation steps and structural settings are the same as in Example 1, specifically:

[0030] The original flue gas cooling device, the spray water cooling device and the net flue gas heating device share a cold source heat pump 19; in the step (1), step (2) and step (3), the common cold source heat pump 19 performs The heat is circulated and transported so that the recovery of water in the flue gas can be uniformly planned; the preferred method is that in the step (1), the raw flue gas before wet desulfurization is cooled by the raw flue gas cooling device, The heat carried by the original flue gas is transferred to the cold source heat pump 19; in the step (2), the circulating spray water used in the wet desulfurization treatment flue gas is cooled by the spray water cooling device, and the circulating The heat carried by the spray...

Embodiment 3

[0033] Such as figure 1 As shown, a method and device for recovering water in wet desulfurization flue gas of the present invention, its basic implementation steps and structural settings are the same as those in Example 2, specifically, the following settings are also included:

[0034] The original flue gas cooling device includes a raw flue gas heat exchanger 2 arranged in the original flue 1, and the original flue gas heat exchanger 2 is connected to the cold source heat pump 19 through the cold source heat pump working heat source circulation pipe 18, and the cold source The heat pump working heat source circulation pipe 18 is provided with a cold source heat pump working heat source circulation pump 17; the spray water cooling device includes a cold source heat pump water supply pipe 16 and a cold source heat pump return water pipe 13, and is arranged on the cold source heat pump water supply pipe 16 There is a water supply pump 14, and the cold source heat pump water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com