Self-suction pipeline mixing reactor

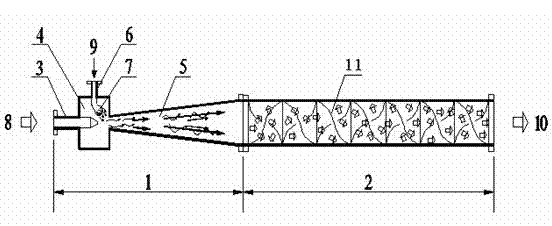

A pipeline mixing, self-priming technology, applied in fluid mixers, chemical/physical/physical-chemical nozzle reactors, mixers, etc., can solve the problem of low mixing efficiency, large reactor volume, and short effective reaction time, etc. problem, to achieve the effect of reducing physical length, good technical effect, and shortening mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Adopt the self-priming pipeline mixing reactor of the present invention to process the wastewater containing cefazolin antibiotic components, with a treatment capacity of 5m 3 / h. Due to the dispersing effect of the distributor, the 3% by weight sodium hydroxide dilute solution is sucked through the fluid distributor, forms dozens of small liquid streams through the small holes of the distributor and enters the waste water fluid, and then passes through the subsequent pipeline The mixer is further mixed evenly, and the pH value of the effluent is stable above 13, which achieves the purpose of pretreatment, and then directly enters the subsequent biochemical treatment station for further treatment.

[0020] The total length of the mixing reactor is 2.6m, the diameter of the mixing section is 100mm, the built-in corrugated packing, and the effective flow area is 50%. The ratio of the lengths of the suction cavity section 4, the diffusion section 5 and the mixing section ...

Embodiment 2

[0023] The wastewater treatment process is the same as in Example 1, and the treatment capacity requirement reaches 10m 3 / h. The total length of the entire suction mixing reactor is 2.6m, the diameter of the mixing section is 125mm, and corrugated packing is built in, and the effective flow area is 50%. The length ratio of the suction chamber section 4, the diffusion section 5 and the mixing section 2 is 1:3:15, the diameter of the fluid inlet pipe 3 is 40mm, and the inner diameter of the suction chamber section 4 is 125mm, the ratio of the two is 40:125 = 3, the suction The diameter of the logistics pipeline 6 is 15 mm, and the ratio of the inner diameter to the suction cavity section 4 is 15:125=1:8.3.

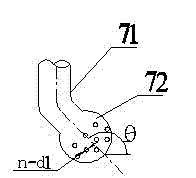

[0024] The position where the fluid distributor 7 penetrates into the suction chamber section 4 is 1 / 3 of the inner diameter of the suction chamber section 4 . The hemispherical hollow cavity 72 of the fluid distributor 7 is provided with n=60 circular holes, the diameter ...

Embodiment 3

[0027] Same as Example 1, the wastewater treatment capacity is required to reach 15m 3 / h. The total length of the entire suction mixing reactor is 3.6 m, the diameter of the mixing section is enlarged to 150 mm, with built-in corrugated packing, and the effective flow area is 50%. The length ratio of the suction chamber section 4, the diffusion section 5 and the mixing section 2 is 1:4:20, the diameter of the fluid inlet pipe 3 is 40mm, and the inner diameter of the suction chamber section 4 is 150mm, the ratio of the two is 40:150=1:3.75 , the diameter of the suction flow pipeline 6 is 25mm, and the inner diameter ratio of the suction chamber section 4 is 1:6.

[0028] The position where the fluid distributor 7 penetrates into the suction chamber section 4 is 1 / 4 of the inner diameter of the suction chamber section 4 . The hemispherical hollow cavity 72 of the fluid distributor 7 is provided with n=70 circular holes, the diameter of the circular holes is d=4mm, and the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com