A fine-grained lead-silver ore collector

A collector, lead-silver technology, applied in solid separation, flotation and other directions, can solve the problems of low recovery rate of lead-silver ore, waste of mineral resources, loss of enterprises and countries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

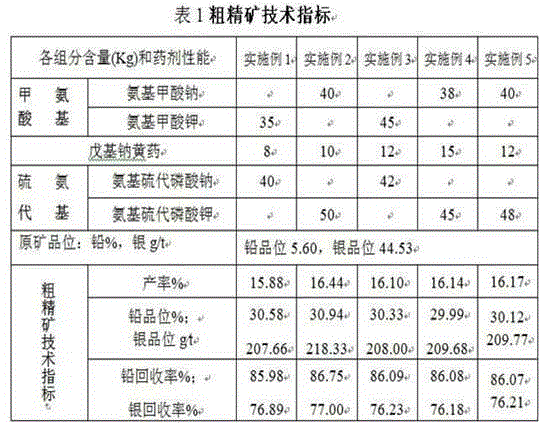

[0010] Example 1 Weighing: Potassium carbamate 35kg, sodium thiophosphate 40kg and amyl sodium xanthate 8kg; the above materials are added to a stirring tank, at normal temperature and pressure, stirring speed 150 rpm, stirring time 45 minutes The collector of the present invention is obtained after stirring and mixing under the technological conditions.

[0011] Under the condition that the grinding fineness is less than 43 microns and accounts for 80%, the collector of this embodiment is used to carry out the beneficiation test on the lead-silver ore. The grade of the lead-silver ore is: lead grade 5.6%, silver grade 44.53g / t. The ore yield is 15.88%, the lead grade in ore dressing is 30.58%, the silver grade is 207.66g / t, the lead recovery rate in ore dressing is 85.98%, and the silver recovery rate in ore dressing is 76.98%.

Embodiment 2

[0012] Example 2 Weighing: 40 kg of sodium carbamate, 50 kg of potassium aminothiophosphate and 10 kg of amyl sodium xanthate; adding the above materials into a stirring tank, at normal temperature and pressure, a stirring speed of 120 rpm, and a stirring time of 60 minutes The collector of the present invention is obtained after stirring and mixing under the conditions.

[0013] Under the condition that the grinding fineness is less than 43 microns and accounts for 80%, the collector of this embodiment is used to carry out the beneficiation test on the lead-silver ore. 30.94%, silver grade 218.33g / t, beneficiation lead recovery rate 86.75%, beneficiation silver recovery rate 77.00%; the collector components and beneficiation test data results in this embodiment are shown in Table 1.

Embodiment 3

[0014] Example 3 Weighing: Potassium Carbamate 45kg, Sodium Thiophosphate 42kg and Amyl Sodium Xanthate 12kg; Add the above-mentioned materials in a stirred tank, at normal temperature and pressure, with a stirring speed of 150 rpm and a stirring time of 50 minutes. The collector of the present invention is obtained after stirring and mixing under the technological conditions.

[0015] Under the condition that the grinding fineness is less than 43 microns and accounts for 90%, the collector of this embodiment is used to carry out the beneficiation test on the lead-silver ore. The grade of the lead-silver ore is the same as in Example 1. 30.33%, silver grade 208.00g / t, beneficiation lead recovery rate 86.09%, beneficiation silver recovery rate 76.23%; the collector components and beneficiation test data results of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com