Drilling equipment for synchronizer hubs

A technology of punching equipment and synchronizer, which is used in drilling/drilling equipment, precision positioning equipment, metal processing equipment, etc. High quality, high machining accuracy, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the present invention.

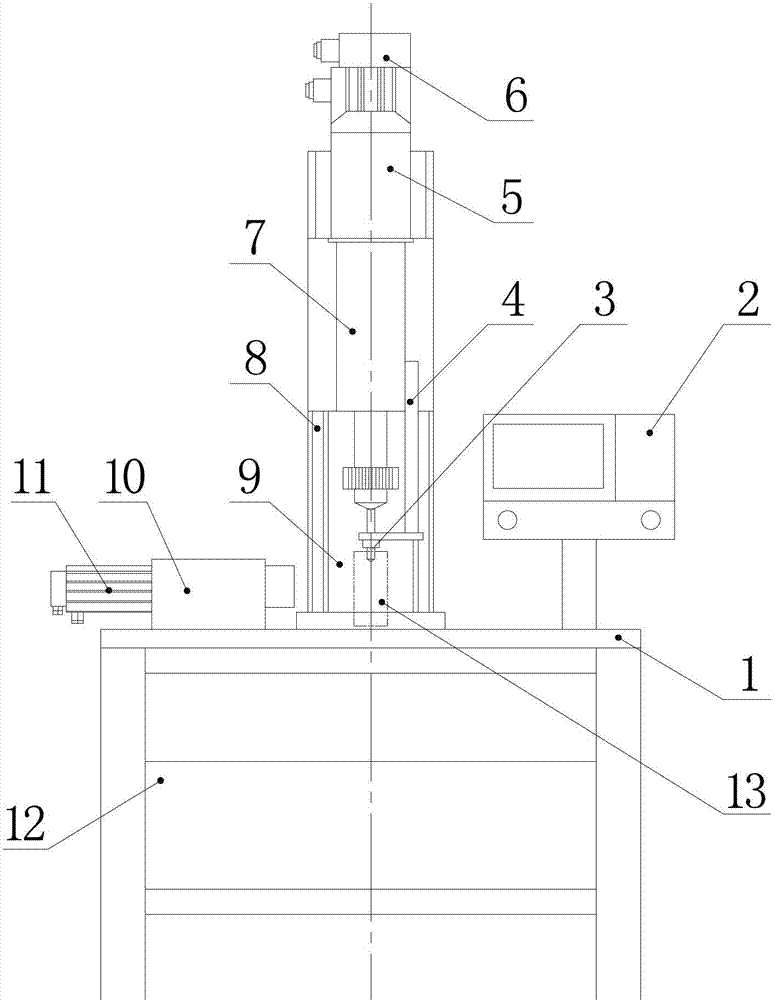

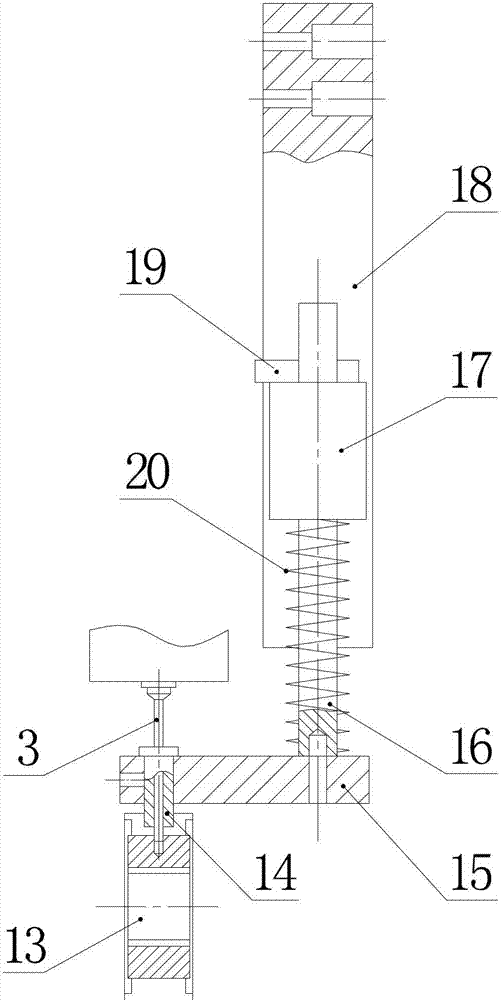

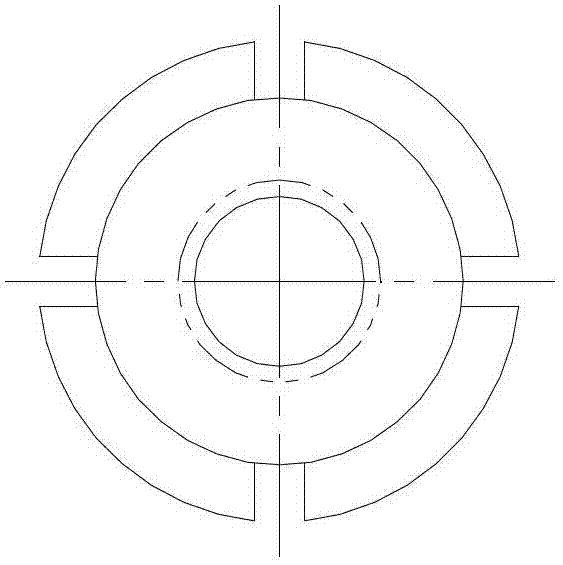

[0024] This embodiment is a punching device for a synchronizer gear hub, such as figure 1 As shown, it includes a working platform 1, a column 9, a head frame 7, and an indexing device; the column 9 is fixedly connected to the working platform 1, and the column 9 is provided with a first servo motor 6, a feed mechanism, and a linear guide rail 8, and the first Servo motor 6 is fixedly connected on the column 9, and the feed mechanism is connected with the first servo motor 6, and the feed mechanism and the linear guide rail 8 are connected by sliding fit; the head frame 7 is fixedly connected on the feed mechanism, and the head frame 7 is provided There is a spindle motor 5, and a drill bit 3 is connected to the spindle motor 5; the indexing device is fixed on the working platform 1, and the indexing device includes a second servo motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com