Electrochemical machining device and method for internally-oblique micro line segment gear

A processing device and micro-segment technology, which is applied to electric processing equipment, special circuits for processing, components with teeth, etc., can solve the problems of tool wear, easy deformation, and high manufacturing costs, and achieve improved processing efficiency and processing accuracy. High-precision and stable machining, ensuring the effect of forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

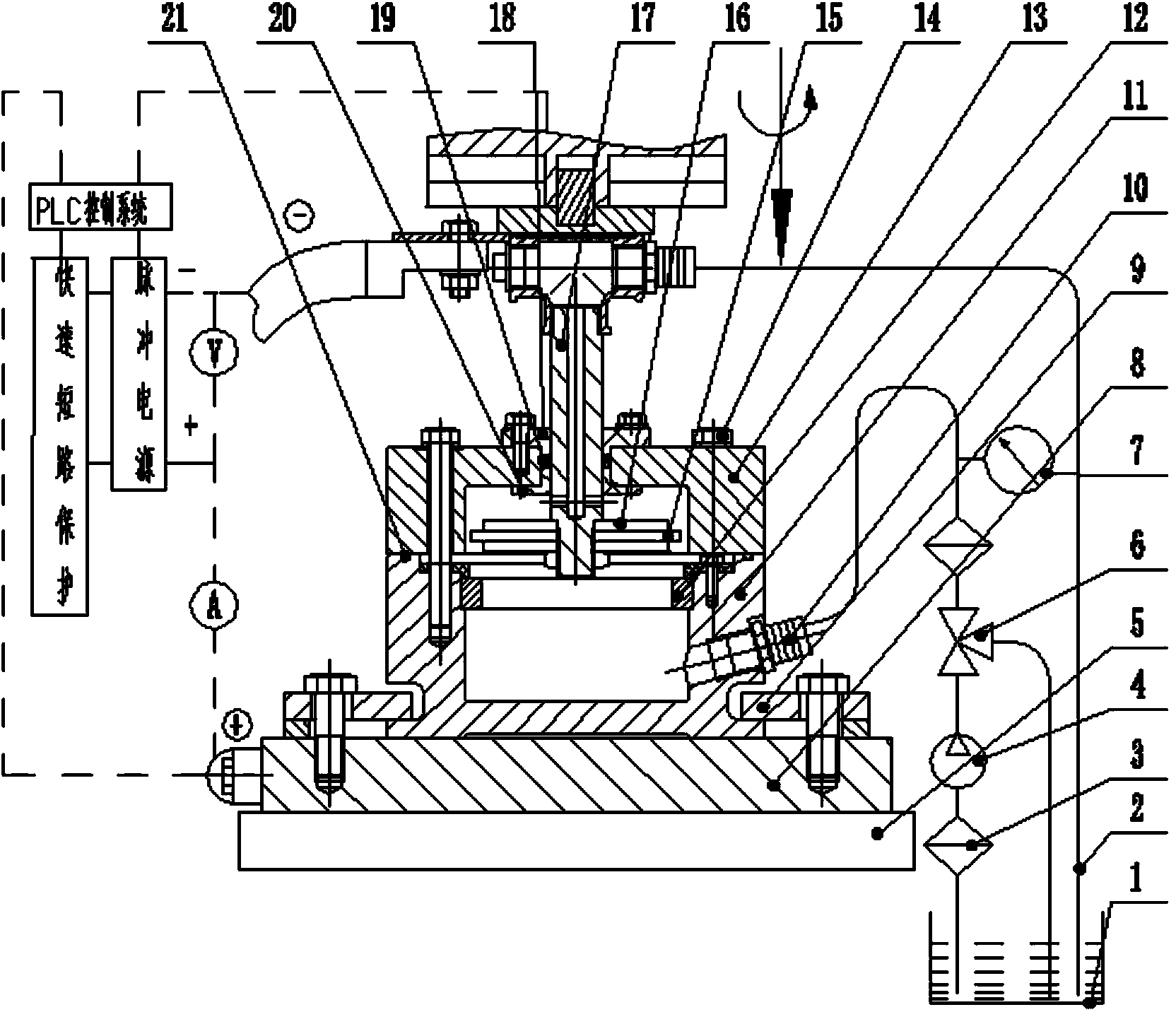

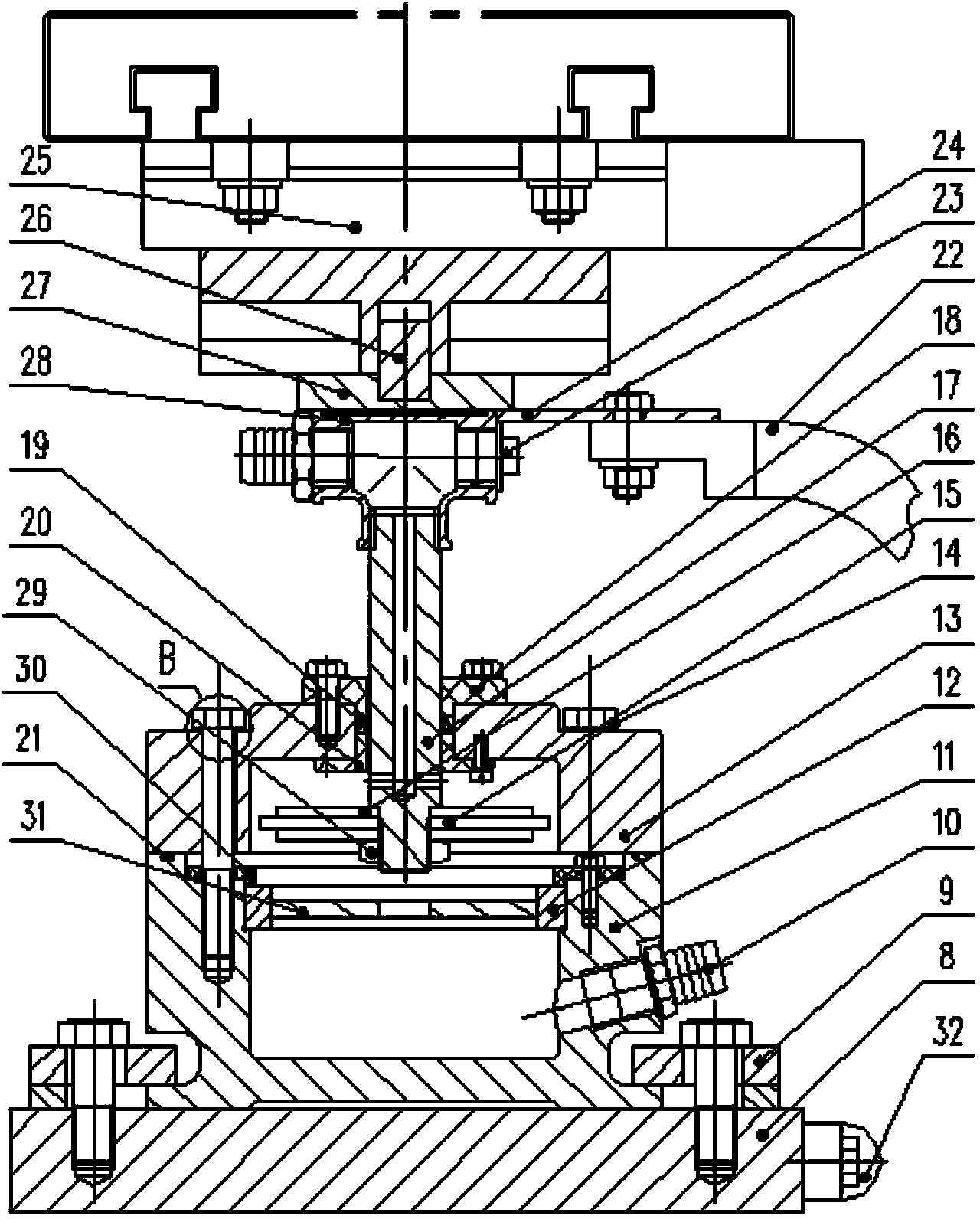

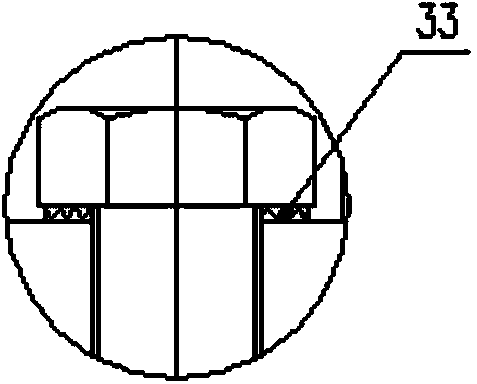

[0030] Referring to the accompanying drawings, an electrolytic processing device for internally inclined micro-segment gears, including a power supply system, a PLC control system, a processing machine tool feed system, an electrolyte circulation and filtration system, a numerical control turntable, a cathode system, a workpiece 12, a workpiece fixture, and a sealing part , the centering part of the workpiece, and the machine tool table 5. Wherein the cathode system includes a flat flange 27, a right-angle tee pipe 28, a plug 23, a hydraulic hose joint 10, a cathode rod 17, a cathode piece 15, a cathode block 16, a hexagonal thin nut 29, and the tool cathode piece 15 is installed on On the shaft shoulder of cathode rod 17 one end, and add a cathode block 16 respectively on both sides to improve the rigidity of cathode sheet 15, be fixed on one end of cathode rod 17 together by hexagonal thin nut 29; The other end of cathode rod 17 is threaded Connect to one end of the right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com