Polyolefin pipe with high strength and high oxygen barrier properties and preparation method thereof

A polyolefin, high-resistance technology, applied in the field of polyolefin pipes and its preparation, to achieve the effects of improving economic benefits, easy to obtain sources, and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Blend 100 parts of HDPE and 1 part of PET resin evenly, then put them into a twin-screw extruder to melt, and extrude through a rotating extruder head and a "melt shrinkage traction-cooling and sizing" device. The temperature of the melting section of the screw is The temperature of the die is 260°C, the temperature of the die is 250°C, the extrusion uses the mandrel to rotate relative to the die, the mandrel rotation speed is 6rpm, and in the stretching process, the diameter of the die is 40mm, the diameter of the sizing sleeve is 32mm, the screw The rotation speed is 60rpm, and the traction speed is 0.3m / min.

[0034] The hoop tensile strength of the obtained pipe is 38.3MPa, and the oxygen transmission rate is 48.6mm 3 / m 2 *24h*0.1MPa. Compared with the traditional extruded HDPE pipe, its hoop tensile strength increased by 7.9%, and its oxygen transmission rate decreased by 7%.

Embodiment 2

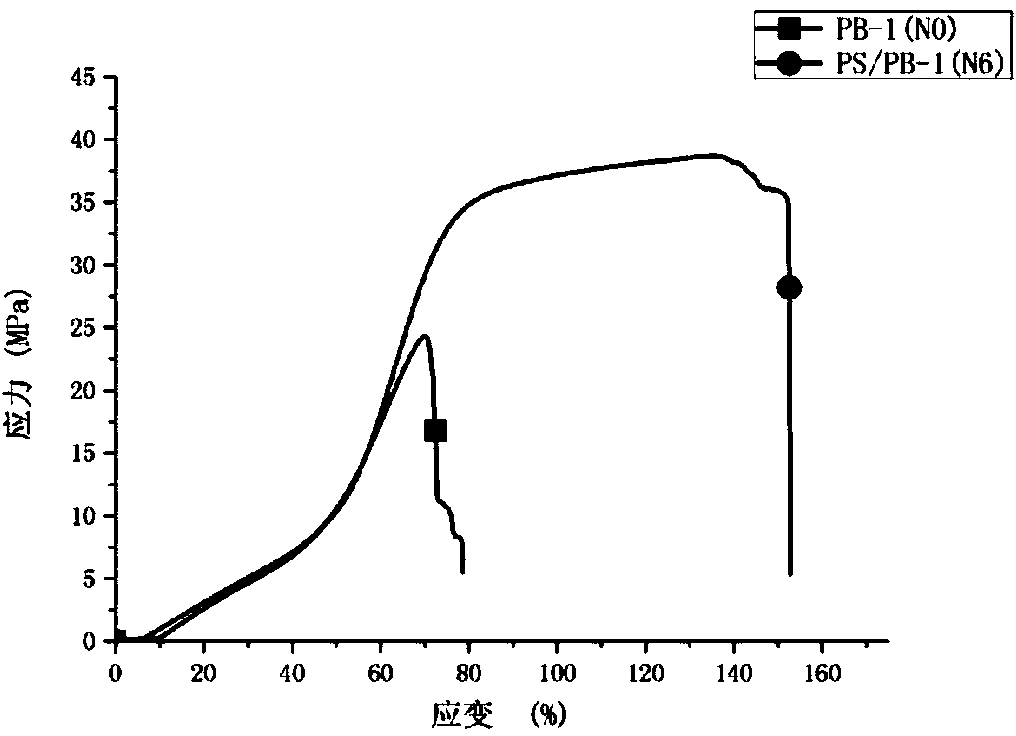

[0036] Blend 100 parts of PB-1 and 10 parts of PET resin evenly, then melt them in a twin-screw extruder, extrude through a rotating extruder head and a "melt shrinkage traction-cooling and sizing" device, and the screw melts The temperature of the section is 260°C, the temperature of the die is 260°C, the extrusion uses the mandrel to rotate relative to the die, the mandrel rotation speed is 6rpm, and in the stretching process, the diameter of the die is 40mm, and the diameter of the sizing sleeve is 20mm , the screw speed is 30rpm, and the traction speed is 0.2m / min.

[0037]The hoop tensile strength of the obtained pipe is 36.9MPa, and the oxygen transmission rate is 12.3mm 3 / m 2 *24h*0.1MPa. Compared with the traditional extruded PB-1 pipe, its hoop tensile strength increased by 15%, and its oxygen transmission rate decreased by 22%.

Embodiment 3

[0039] Blend 100 parts of PPR and 20 parts of PET resin evenly, then put them into a twin-screw extruder to melt, and extrude through a rotating extruder head and a "melt shrinkage traction-cooling and sizing" device. The temperature of the melting section of the screw is The temperature of the die is 280°C, the temperature of the die is 280°C, the extrusion adopts the rotation of the mandrel relative to the die, and the rotation speed of the mandrel is 6rpm, and in the stretching process, the diameter of the die is 40mm, the diameter of the sizing sleeve is 16mm, and the screw The rotation speed is 20rpm, and the traction speed is 0.3m / min.

[0040] The hoop tensile strength of the obtained pipe is 40.5MPa, and the oxygen transmission rate is 13.4mm 3 / m 2 *24h*0.1MPa. Compared with traditional extruded PPR pipes, its hoop tensile strength has increased by 32%, and its oxygen transmission rate has decreased by 28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com