Electric control system and control method for air-core winding

An electrical control system and electrical control technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of low work efficiency, complicated operation, slow winding speed, etc., to improve production efficiency and compact mechanical structure , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

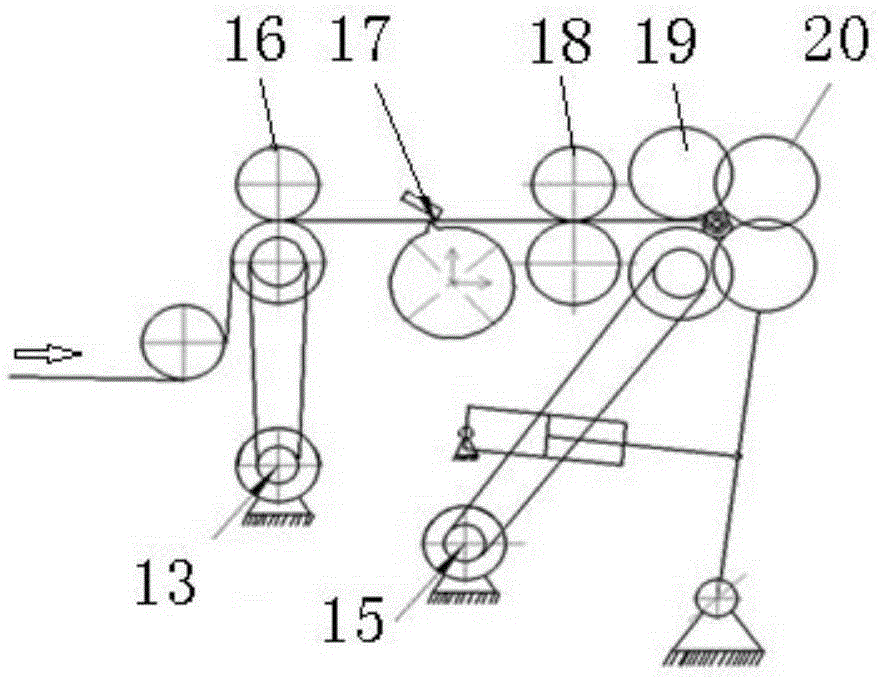

[0013] like figure 1 As shown, the hollow-core rewinding electrical control system of the present invention has the mechanical structure of its control object, including a primary traction group 16, a cutting knife group 17, a secondary traction group 18, a fixed winding Part 19 and swing winding group 20 cooperate and coordinate with each other.

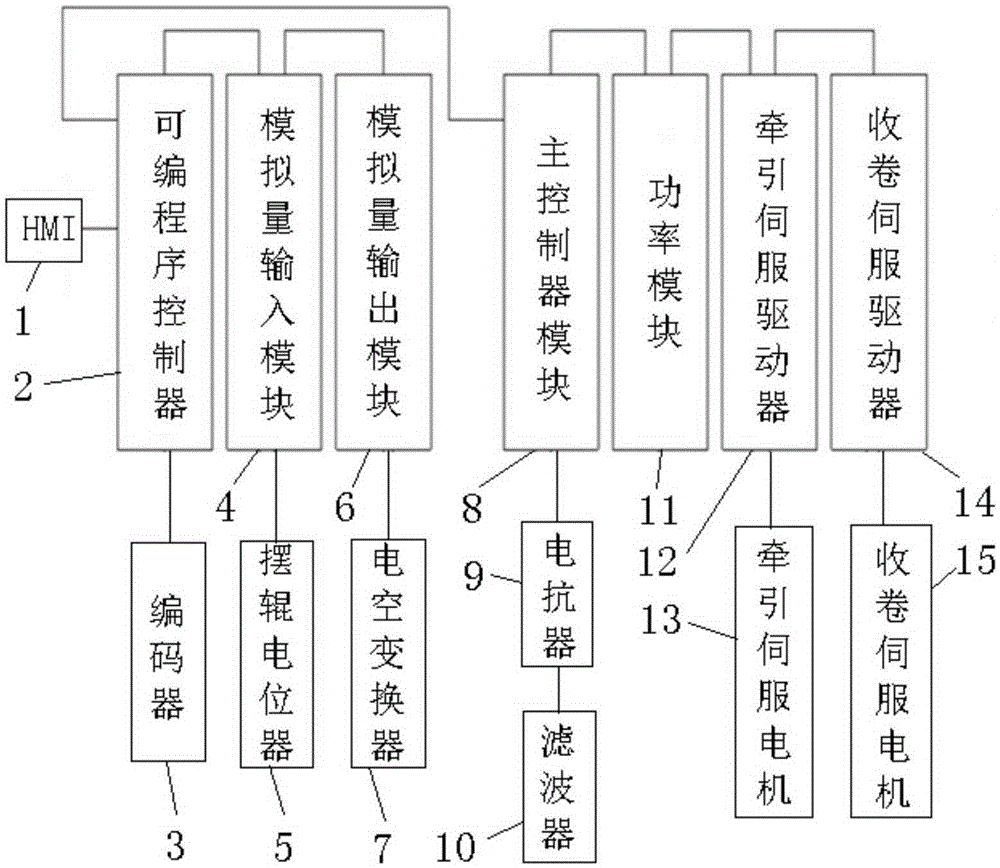

[0014] see figure 2 , the control block diagram of the embodiment of the electric control system of the air-core winder of the present invention is, including a programmable controller 2, and the programmable controller 2 is connected with HMI1, encoder 3, analog input module 4 and main controller respectively The module 8 is connected; the analog input module 4 is respectively connected with the pendulum roller potentiometer 5 and the analog output module 6, and the analog output module 6 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com