A pipe network type feces and organic sewage garbage treatment device

A garbage treatment device and organic sewage technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, biological sludge treatment, etc., can solve problems such as difficult mixing, high construction cost, and complicated design, and achieve The effect of short construction time, low construction cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

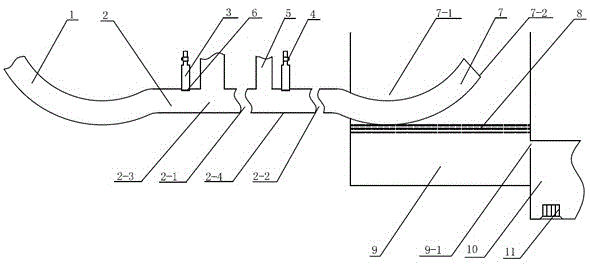

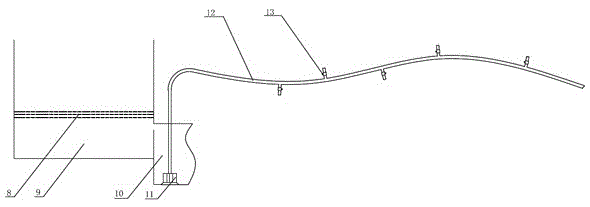

[0023] As shown in the attached figure: a pipe network type excrement and organic sewage garbage treatment device, including: anaerobic fermentation part, gravity filter part and fertilizer water transport part.

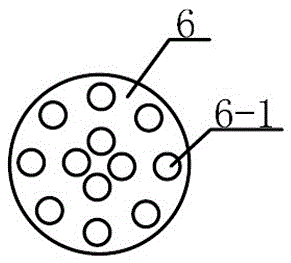

[0024] The anaerobic fermentation part includes: the first collecting elbow 1, the anaerobic fermentation pipe 2, the biogas output pipe 3, the biogas intake valve 4, the second collecting elbow 5, the bottom surface of the output pipe 6, the filter air hole 6- 1. Fertilizer and water discharge elbow 7, the first collecting elbow 1 is connected to anaerobic fermentation pipe 2, anaerobic fermentation pipe 2 is connected to biogas output pipe 3, biogas intake valve 4 is installed on biogas output pipe 3, biogas output pipe The bottom of 3 has an output pipe bottom surface 6, and there is a filter air hole 6-1 on the output pipe bottom surface 6, and several second collection elbows 5 are connected on the anaerobic fermentation pipe 2, and the right end of the anaerobic...

Embodiment 2

[0031] Others are the same as the first embodiment, the fertilizer water outlet 7-2 is 10 to 30 cm higher than the level of the second anaerobic extension pipe 2-2. The biogas output pipe 3 extends into the anaerobic fermentation pipe 2 by 3 cm.

[0032] The effect is the best when the fertilizer water outlet 7-2 is 20cm higher than the second anaerobic extension pipe 2-2 through comparison. After comparison, the effect is the best when the methane output pipe 3 stretches into 2 cm in the anaerobic fermentation pipe 2.

Embodiment 3

[0034] Others are the same as in Embodiment 1, the inclination angle of the anaerobic fermentation pipe 2 along the sewage flow direction is 5°, and the time for feces and organic sewage garbage to flow in the anaerobic fermentation pipe is 15 days to 30 days.

[0035] The working principle and using method of the present invention are: feces and organic sewage garbage are collected into the first collection elbow 1 and flow through the first anaerobic collection pipe 2-3, the first anaerobic extension pipe 2-1, the second anaerobic collection pipe Pipe 2-4 and the second anaerobic extension pipe 2-2, the second anaerobic extension pipe 2-2, the first anaerobic collection pipe 2-3 and the second anaerobic Collection pipes 2-4 collect different feces and organic sewage waste.

[0036] The biogas output pipe 3 is inserted into the anaerobic fermentation pipe 2 by 2 cm, so that the bottom surface 6 of the output pipe is in the place where the sewage flows, and it can be ensured t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com