Pipe-jacking type cable sleeve passage construction method

A technology of cable casing and construction method, which is applied in the direction of cable laying equipment, tunnels, tunnel linings, etc., can solve the problems of long distance between stations and substations, difficulty in implementation, and many obstacles, so as to speed up the construction progress, reduce the cost, and The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

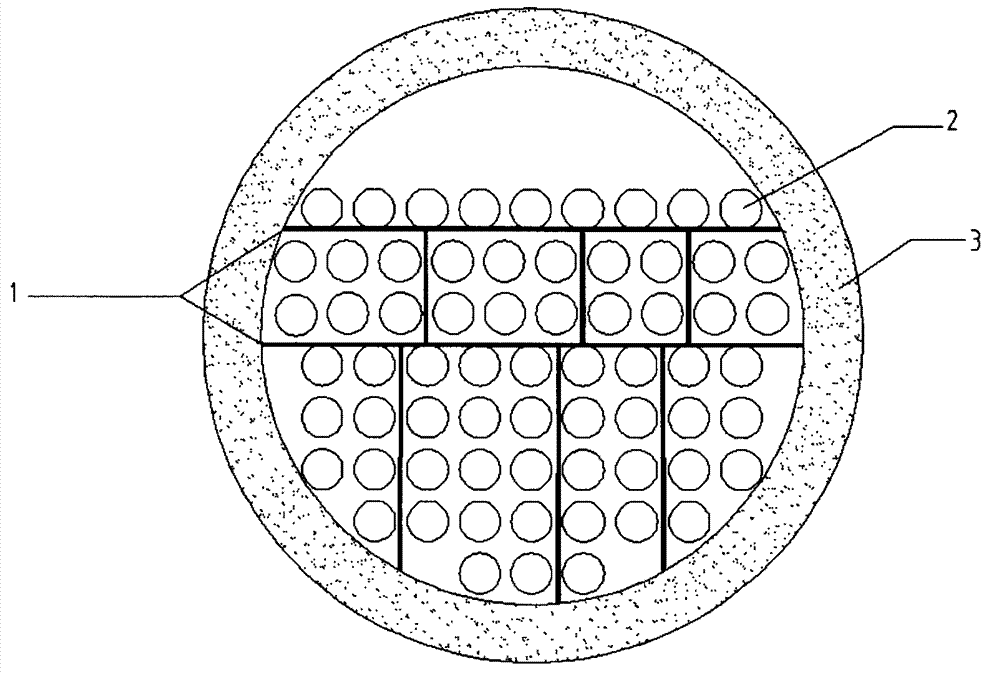

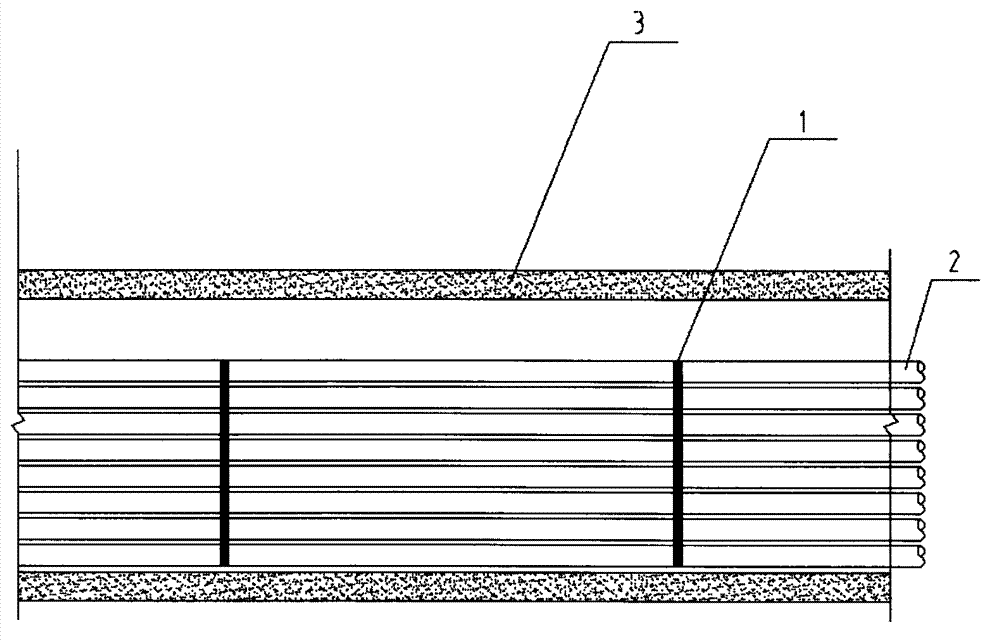

[0027] Embodiment 1: A construction method for a jacking type cable casing channel, including the steps of caisson construction for a terminal cable well, pipe jacking construction, pipe arrangement construction, concrete pouring, and cable threading.

[0028] 1. Caisson construction of terminal cable well

[0029] The caisson process flow is as follows: preparatory work → removal of brick tire formwork and plain concrete cushion → chiseling → soil extraction and sinking → sinking speed control → caisson correction → caisson bottom sealing and floor concrete pouring.

[0030] The following points should be paid attention to during the process:

[0031] groundwater control

[0032] If the cable shaft encounters a silt layer during the sinking process, in order to prevent sand from escaping, the surrounding area of the caisson can be isolated by stirring piles, a multi-axis machine can be used, or a jetting pile can be used to form a water-stop curtain, and a tube well can be...

Embodiment 2

[0081] The power of a subway station station is introduced from the main station on the west side, with a total length of about 1,150 meters. The surrounding environment of the section of more than 200 meters is relatively complicated, and it needs to pass through canals, gravel yards, and oil depots.

[0082] Due to the impossibility of excavation in this section, relatively economical medium-diameter pipe jacking (1.8m inner diameter) was adopted for construction. The bottom elevation of the pipeline in the pipe jacking area of this project is -8.3m~-6.0m, and the buried depth is about 6.5m~10m. It mainly passes through the silt layer and silty clay layer. Mud water balance method.

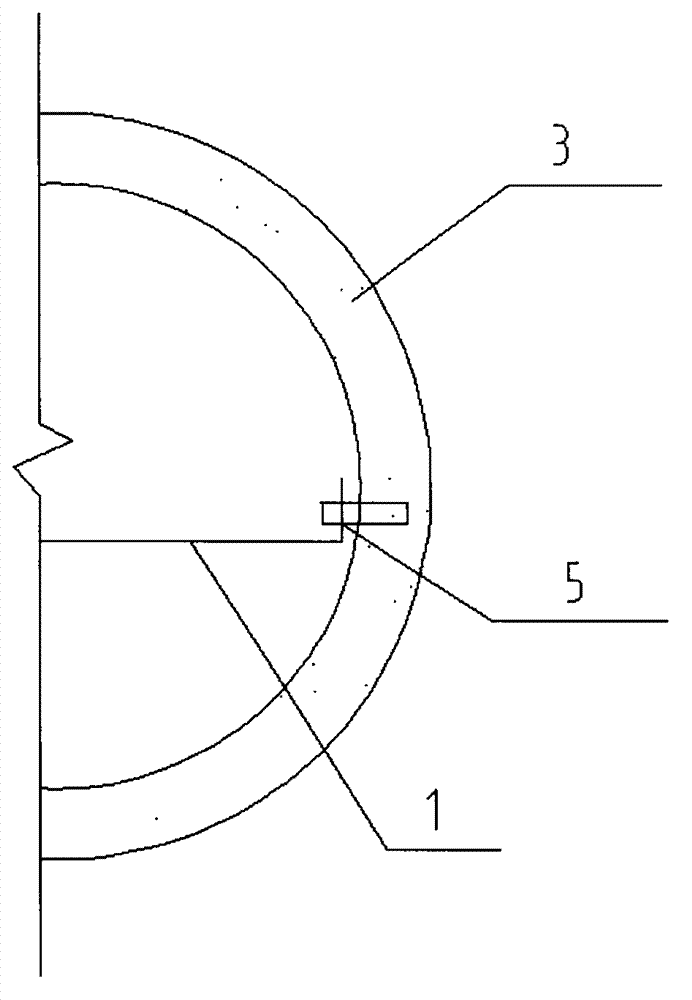

[0083] Two cable wells are set at the end of the pipe jacking. The 7# working well is a round well with a diameter of 8.5m and a depth of 10.5m; the 9# receiving well is a square well with a plane size of 9.3m×6.3m and a depth of 8.0m. The water-stop curtain is constructed around the well wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com