Method for achieving optimizing control of load of thermal power generating unit in PROPR mode

A load optimization control and thermal power unit technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems that affect the adjustment accuracy and response time, the influence of unit load control accuracy, and the large fluctuation of main steam pressure, etc. , to achieve the effect of improving adjustment accuracy and response time, ensuring control quality and assessment indicators, and ensuring the balance between supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

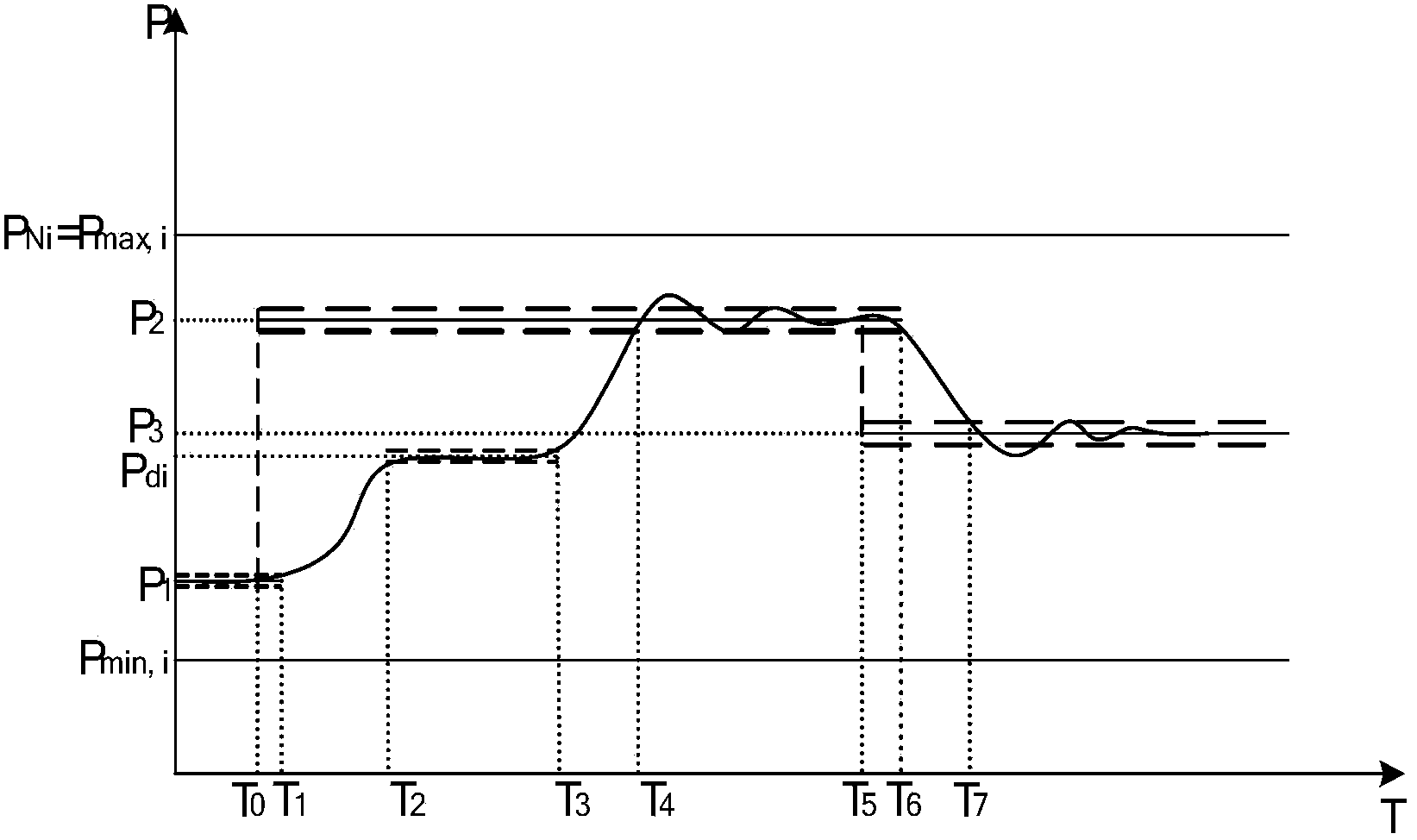

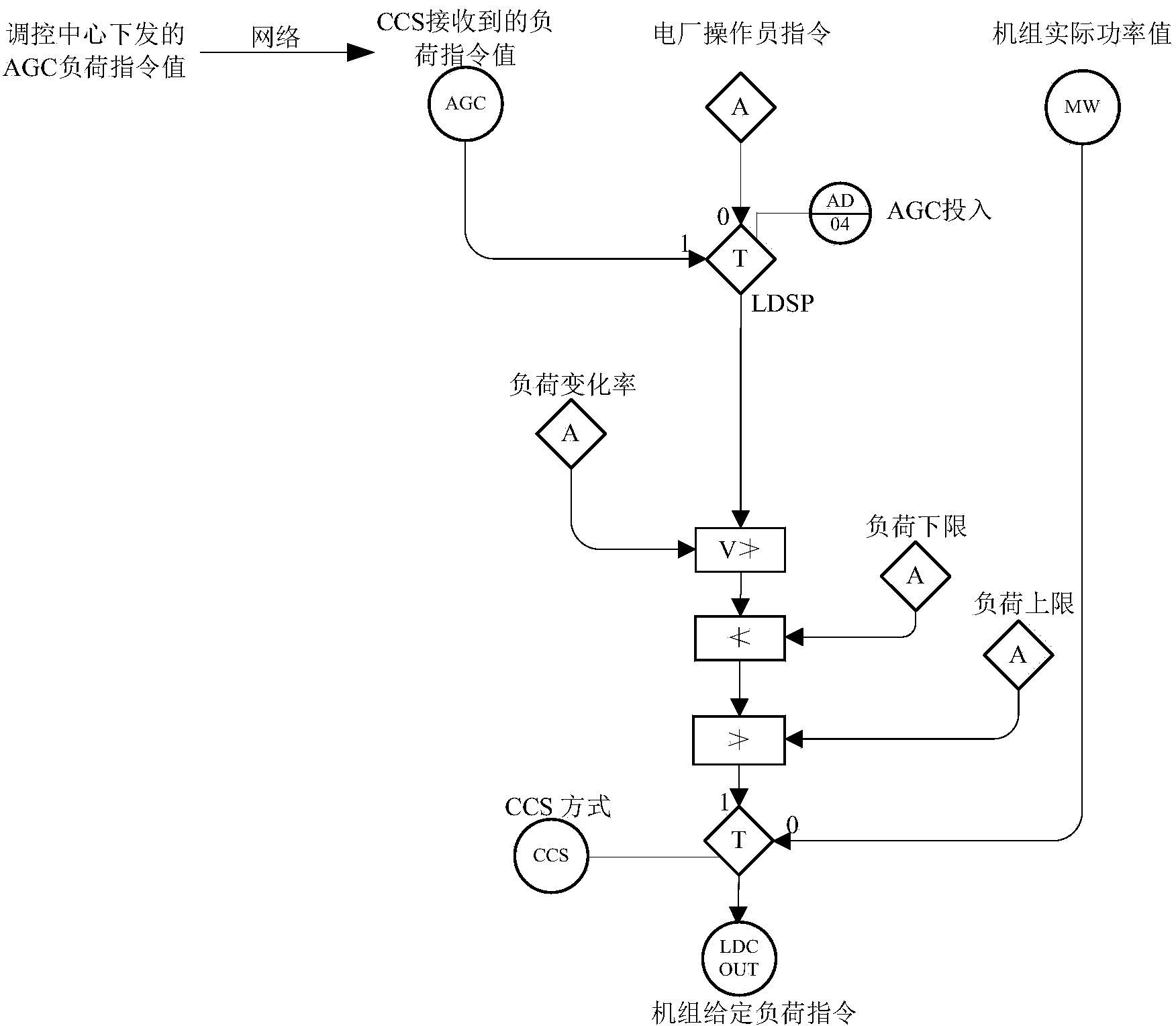

[0035] Such as Figure 4 , Figure 5 As shown, it is applied in a 300MW subcritical, intermediate reheating, and condensing coal-fired unit.

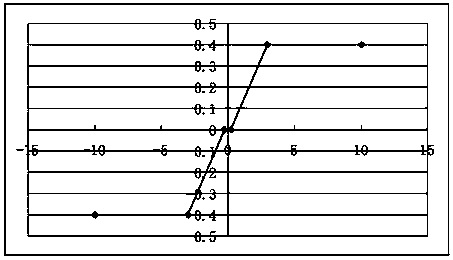

[0036] (1) Because the load range of dispatching and assessment units is generally 50%-100% of rated power, it is only necessary to correct the load point between 150-300MW, and use the GPS synchronous time synchronization system to take out the dispatching center at the same time point The AGC load command value sent by the CCS and the load command value received by the CCS are sent to the subtractor module to find out the deviation at the specified load point, and superimpose the deviation on the original command value to generate a nonlinear correction function F (x), as shown in Table 1.

[0037] Table 1

[0038]

[0039]

[0040] (2) Send the corrected AGC load command value and the actual power va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com