Electronic component and manufacturing method thereof

A technology of electronic components and manufacturing methods, which is applied in the direction of assembling printed circuits with electrical components, transformer/inductor shells, transformer/inductor coils/windings/connections, etc., can solve the problem of small current and low magnetic permeability of magnetic core powder. , Unable to high power, high current, high inductance performance at the same time showing better performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

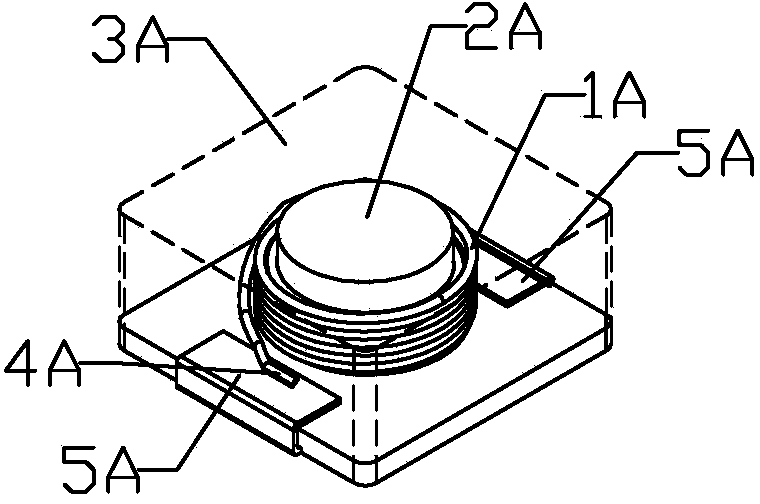

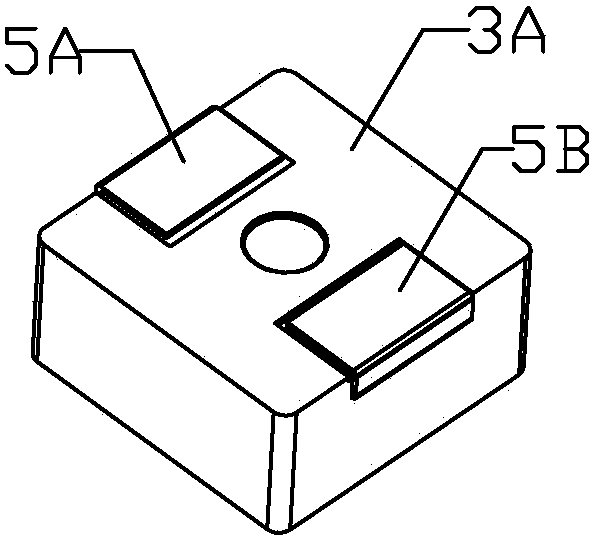

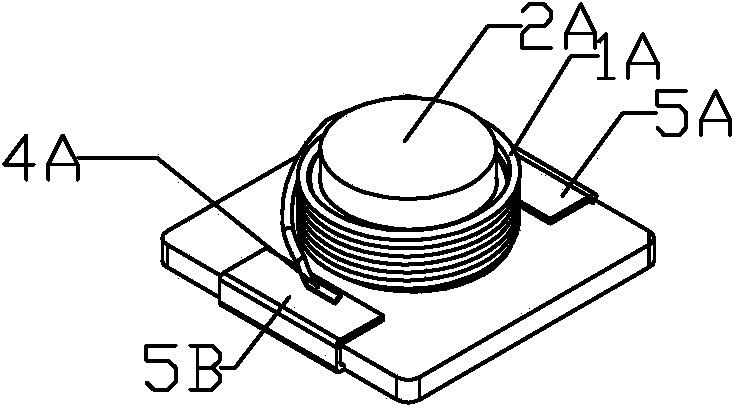

[0071] The electronic component and its manufacturing method of the present invention will be further described in detail below with reference to the accompanying drawings.

[0072] Such as Figure 1 to Figure 40 As shown, the present invention is an electronic component, which is characterized in that: the electronic component includes an inner core and an outer cladding layer (3A, 3B, 3C, 3D, 3E, 3F, 3G), and the inner core is located In cladding; said inner core comprising coil windings (1A, 1B, 1C, 1D, 1E, 1F, 1G) and coil assembly, printed circuit and printed circuit assembly comprising a body and extensions from said body (4A, 4B, 4C, 4D, 4E, 4F, 4G, 4H, 4I, 4J, 4L, 4M, 4N) and extensions are connected to terminals (5A, 5B, 5C, 5D, 5E, 5F) by welding or spot welding , 5G), the formed electrode; the outer cladding layer is to adopt a pressurized method to embed the inner core in the slurry mixture material by extrusion molding or casting or embedded casting, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com