High-wave transmission hollow-structure radome

A radome and hollow technology, which is applied in the field of communication reception, can solve the problems of increased difficulty in antenna design and low electromagnetic wave transmittance, and achieve the effects of light-weight and high-strength manufacturing technology, novel and unique structure, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

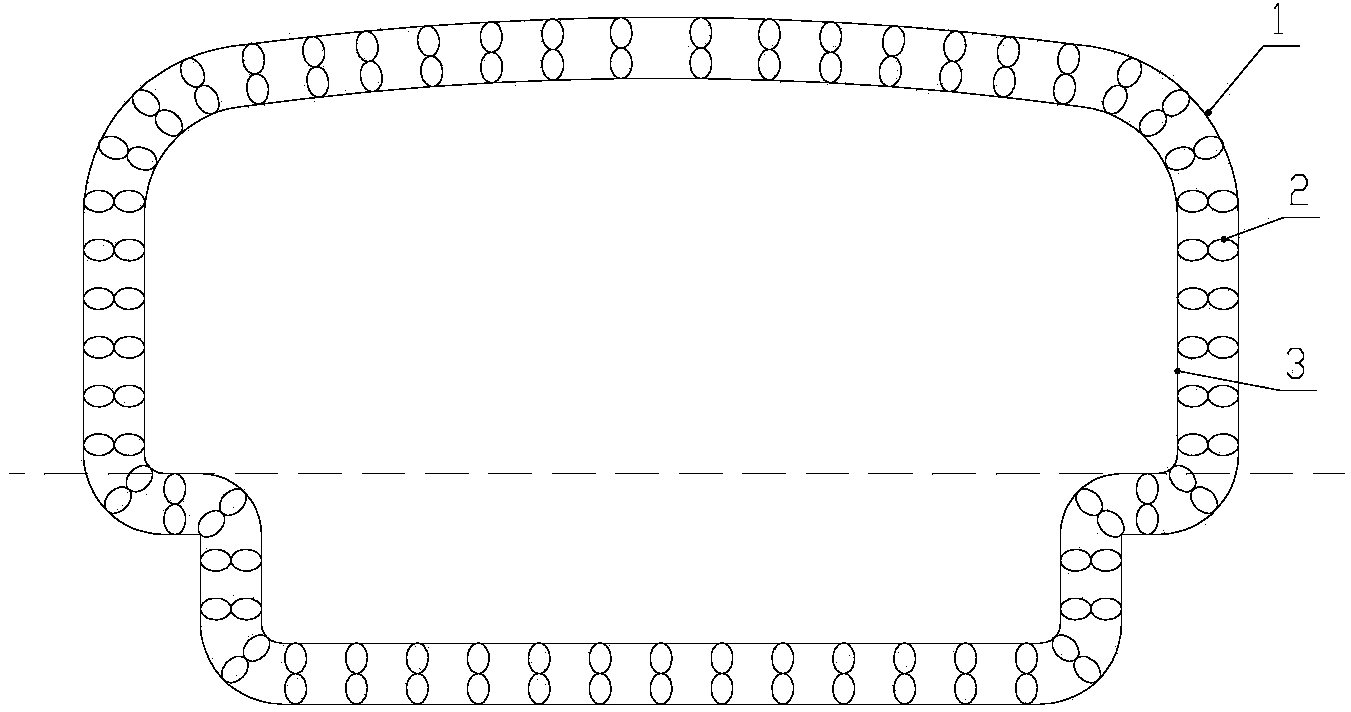

[0024] Such as figure 1 The shown high-transparency hollow structure radome includes a radome body, and the side wall of the radome body includes a hollow fabric layer; the inner surface of the hollow fabric layer is compounded with an inner composite material layer; the outer surface of the hollow fabric is compounded with an outer layer. A composite material layer; the thickness of the inner composite material layer and the outer composite material layer is 1mm; the dielectric parameter of the inner composite material layer and the outer composite material layer is 2.9; the thickness of the hollow fabric layer is 10mm; The dielectric parameter is 2.6, and the loss tangent value is less than 0.007; the hollow fabric includes an upper surface layer, a core layer and a lower surface layer connected up and down in sequence, and the core layer is composed of fiber fabric units in the shape of "8"; the fiber fabric unit The density is 80000pcs / m 2 ; The shape of the longitudinal ...

Embodiment 2

[0030] It is basically the same as Example 1, except that the thickness of the inner composite material layer and the outer composite material layer are both 0.5mm; the dielectric parameters of the inner composite material layer and the outer composite material layer are 2.0; the hollow fabric The thickness of the layer is 2㎜; the dielectric parameter is 2.9, the loss tangent value is less than 0.007; the density of the fiber fabric unit is 10000 / m 2 ;

[0031] The resin glue is polyimide ester resin, and the merchant is Huizhi Technology (China) Co., Ltd., brand PI-031.

[0032] The fibers used in the hollow fabric layer, the inner composite material layer and the outer composite material layer are all basalt fibers.

Embodiment 3

[0034] It is basically the same as Example 1, except that the thickness of the inner composite material layer and the outer composite material layer are both 2.0mm; the dielectric parameters of the inner composite material layer and the outer composite material layer are 2.8; the hollow fabric The thickness of the layer is 15.0㎜; the dielectric parameter is 2.5, the loss tangent value is less than 0.007; the density of the fiber fabric unit is 200000 / m 2 ;

[0035] The resin glue is cyanate ester resin, and the merchant is Yangzhou Tianqi Chemical Co., Ltd., the brand name is CE01MO.

[0036] The fibers used in the hollow fabric layer, the inner composite material layer and the outer composite material layer are all aramid fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com