Compact type glass structure medium-power carbon dioxide laser

A technology of carbon dioxide and lasers, which is applied in the field of lasers, can solve the problems of difficult configuration and the inability to use full transmission output windows for lasers, and achieve the effects of easy alignment, easy alignment adjustment, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

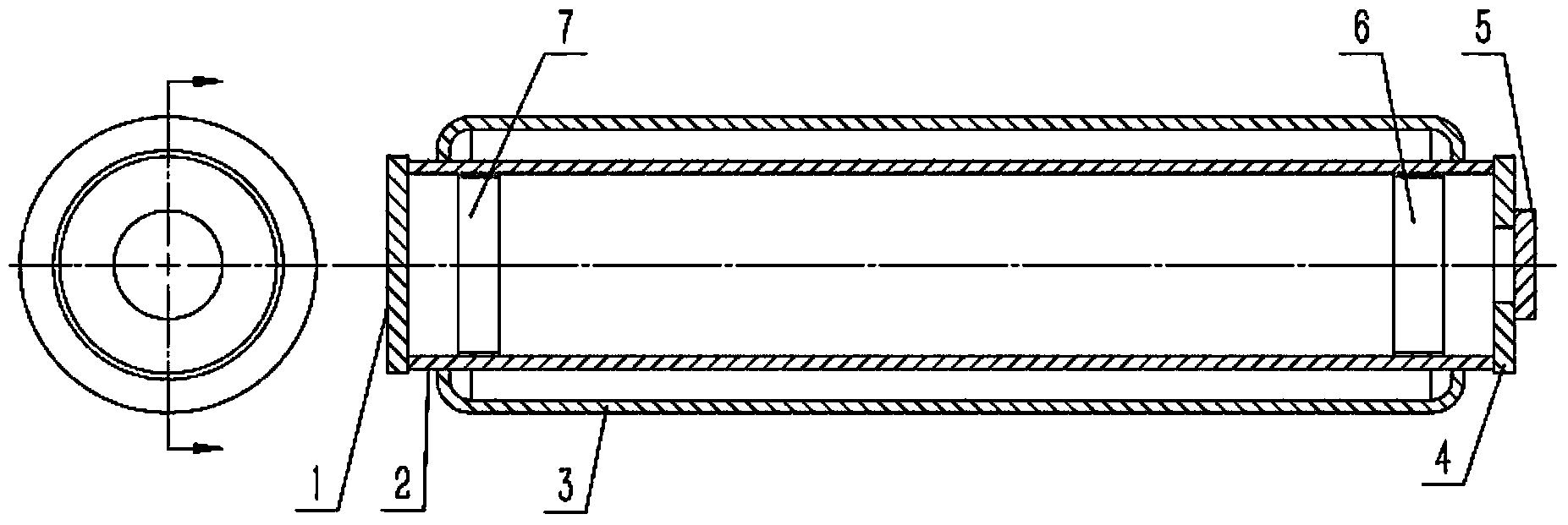

[0024] Such as figure 1 As shown, this embodiment includes: a first reflector 1 , a discharge tube 2 , a water cooling jacket 3 , a second reflector 4 , a transmissive output window 5 , a first electrode 6 and a second electrode 7 .

[0025] The first reflector 1 is an infrared total reflection concave mirror, the second reflector 4 is an infrared total reflection plane mirror with a hole in the center, and the transmissive output window 5 is an optical lens that can pass through infrared. The transmissive output window 5 is packaged in on the second reflector 4. The length of the discharge tube 2 is 1600 mm.

[0026] The shape of the first reflecting mirror 1 is circular, its diameter is 40 mm, and its thickness is 8 mm.

[0027] The shape of the second reflecting mirror 4 is circular, with an outer diameter of 40 mm, an inner diameter of 6 mm, and a thickness of 8 mm.

[0028] The central portion of the second reflecting mirror 4 is a circular hole, and the transmissive o...

Embodiment 2

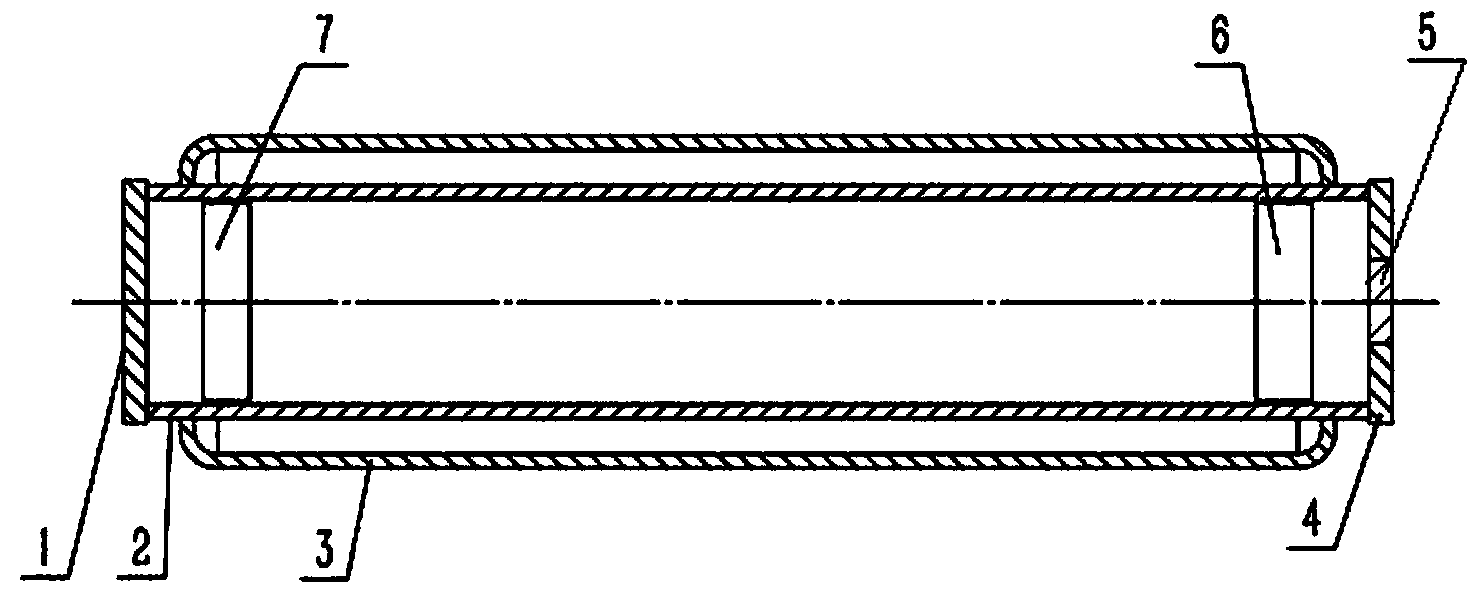

[0036] Such as figure 2 As shown, the basic structure and working principle of this embodiment are the same as those of Embodiment 1.

[0037] The first reflector 1 is an infrared total reflection concave mirror with a diameter of 45mm and a thickness of 8mm, but the second reflector and the transmissive output window 5 at its center are made of the same infrared transmission material (zinc selenide) The comprehensive function of reflection and transmission is realized by coating, that is, the annular inner surface of the transmission material is a total reflection surface, and the central circle part of the material is a transmission output window; the outer diameter of the second reflection mirror 4 is 45mm, 8mm in thickness, and 6mm in diameter of the laser output window in the central circle.

[0038] Compared with Embodiment 1, under the condition that the length of the discharge tube 2 is the same, since the diameter of the resonant cavity sheet at both ends in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com