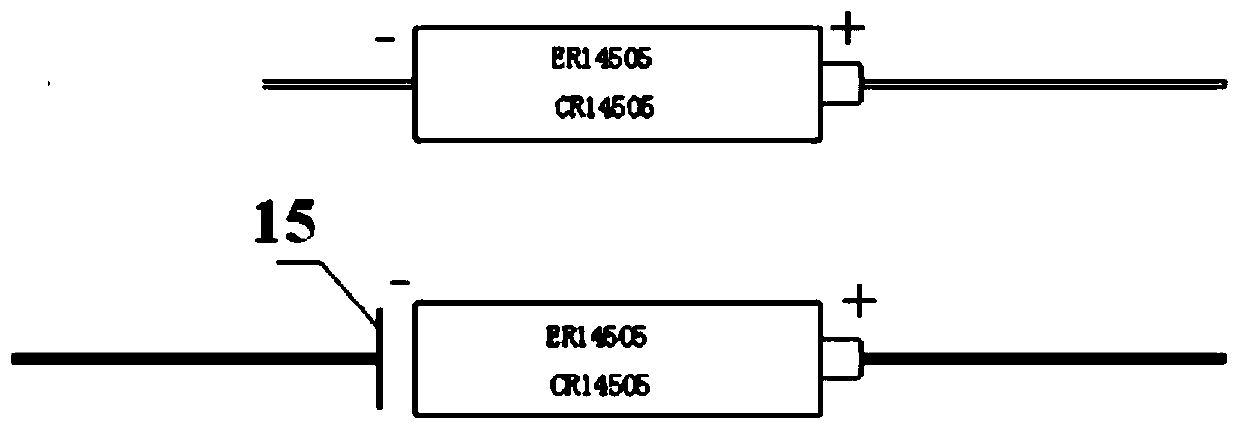

Automatic one-step welding device for cylindrical battery pins

A cylindrical battery, automatic welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of increasing the manufacturing cost of the process, restricting the production efficiency, increasing the material cost of a single product, etc., and reducing the material cost. , The effect of improving production efficiency and reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

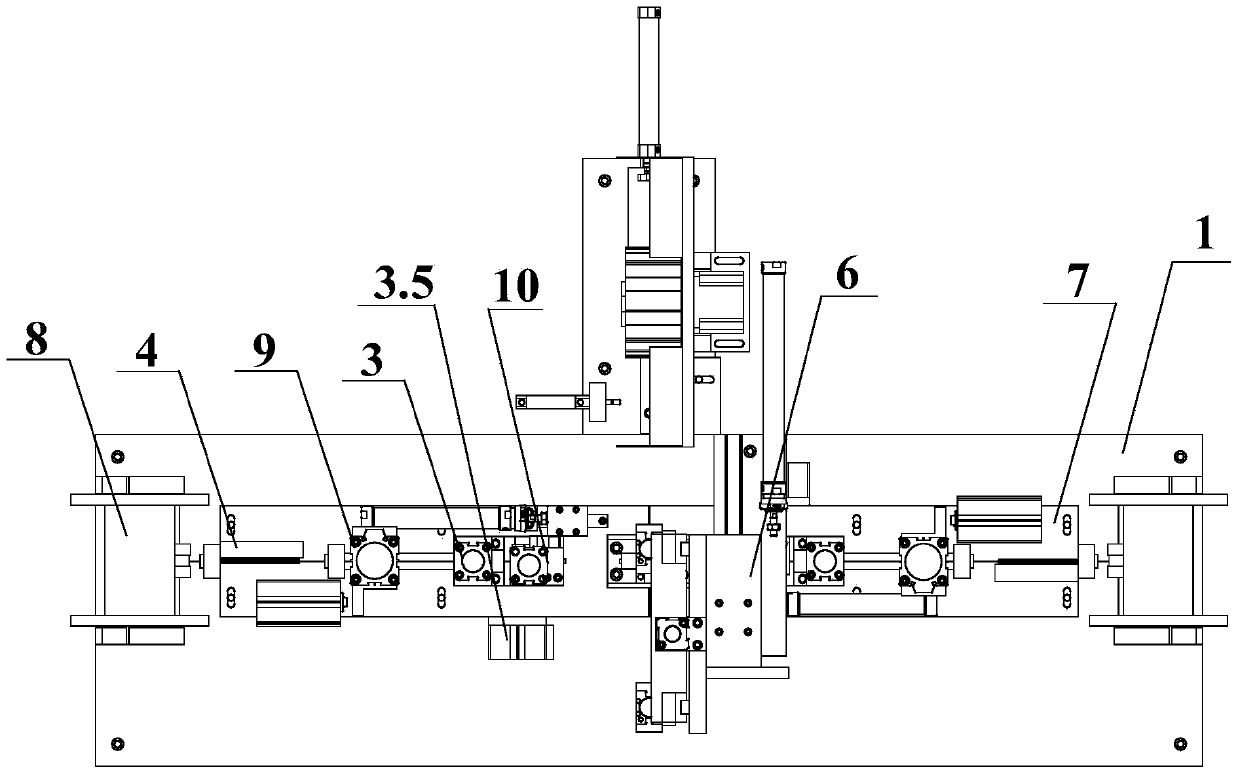

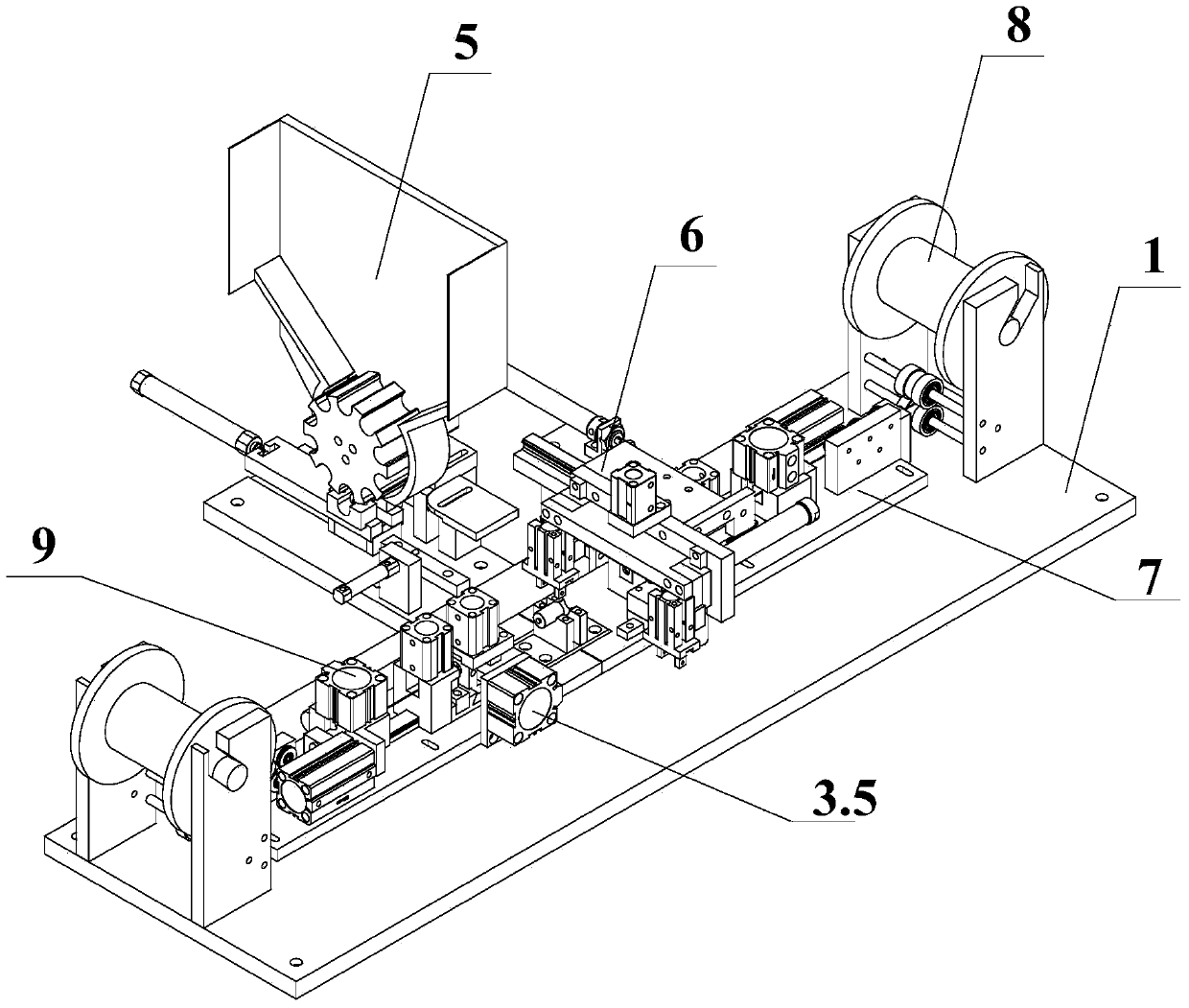

[0046]A one-time automatic welding device for cylindrical battery lead pins, the automatic welding device includes a fixed plate 1, the fixed plate 1 is in the shape of a "T", and a movable plate 7 is movably arranged on the fixed plate 1, and the center of the movable plate 71 is fixedly arranged There is a welding positioning mold 2, with the welding positioning mold 2 as the center, and its horizontal sides are symmetrically provided with a movable battery welding nozzle device 10, an electrode wire cutting mechanism 3 and an electrode wire straightening mechanism 4 sequentially from the inside to the outside. An electrode wire length fixing mechanism 9 is arranged between the wire cutting mechanism 3 and the electrode wire strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com