A chemical mechanical polishing method and device

A chemical-mechanical and grinding method technology, used in grinding devices, grinding machine tools, metal processing equipment, etc., can solve problems such as instability, inability to maintain removal rate, reduction of removal rate, etc., and achieve the effect of stable polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

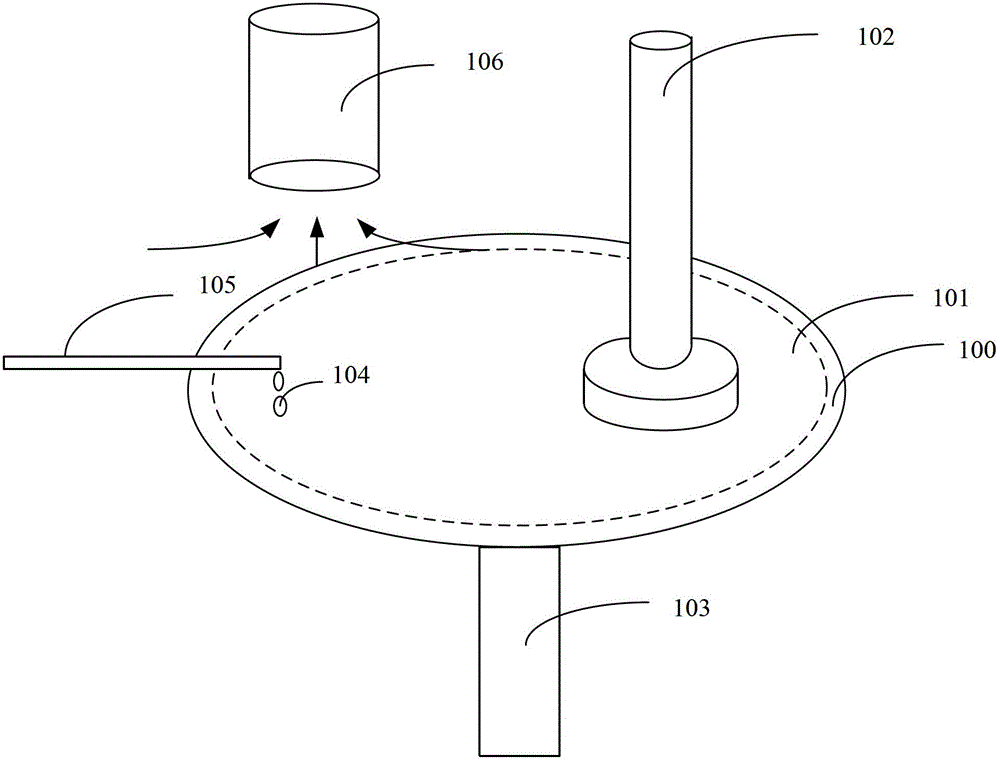

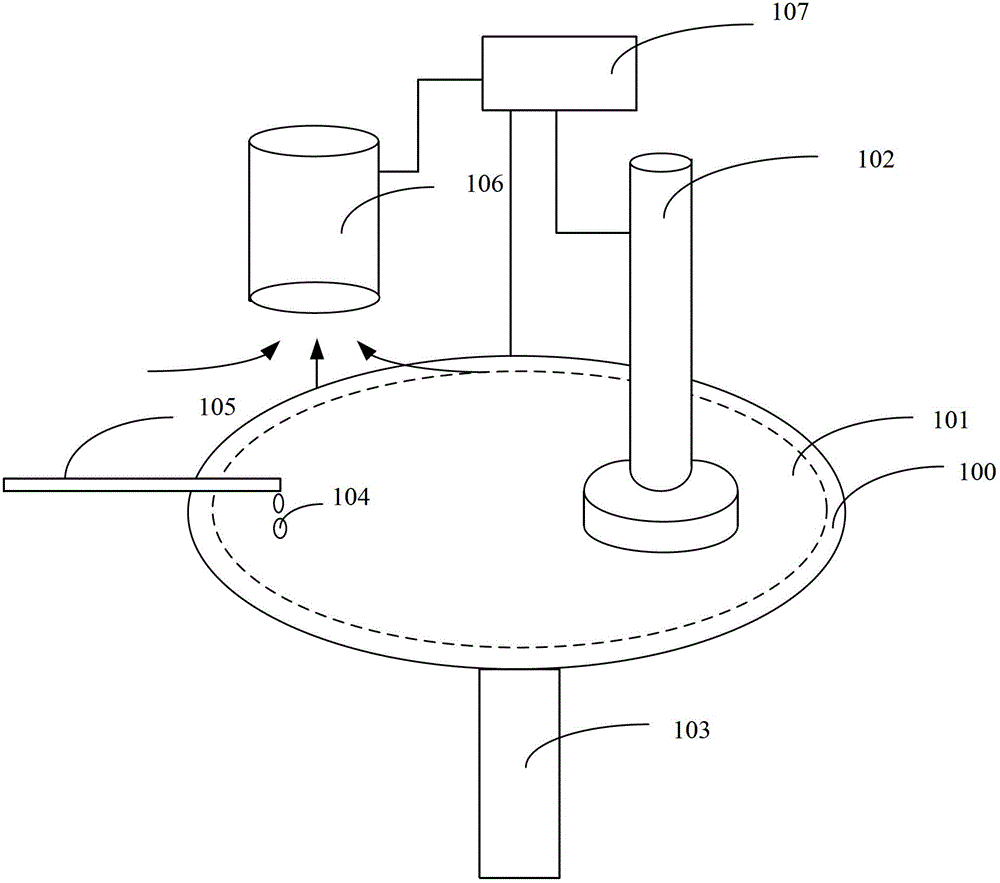

[0025] Such as figure 2 As shown, the present invention provides a chemical mechanical polishing device, which includes: a grinding platform, a polishing rate detection system and an exhaust system, wherein the exhaust system further includes an exhaust port 106, an exhaust fan, an exhaust duct, and an exhaust system. Valves and sensors on the air pipeline (not shown in the figure);

[0026] This chemical mechanical polishing device comprises grinding platform, exhaust system and polishing rate detection system 107 altogether, and wherein, grinding platform is used for carrying out the chemical mechanical grinding of wafer, further comprises: grinding disc 100, the grinding pad 101 that is fixed on the grinding disc 100 1. The grinding head 102 and the grinding fluid supply pipe 105 are driven by a motor, and one end of the rotating shaft 103 below the grinding disc 100 is connected to the driving motor and the other end is connected to the grinding disc 100 . The grinding l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com