Embossing device for embossing non-woven fabric with concave-convex pattern

A technology of embossing and embossing equipment, which is applied in printing, printing presses, rotary printing presses, etc., can solve the problems of poor production quality, low efficiency, easy moisture, etc., to improve hardness and elasticity, high production efficiency, and increase friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

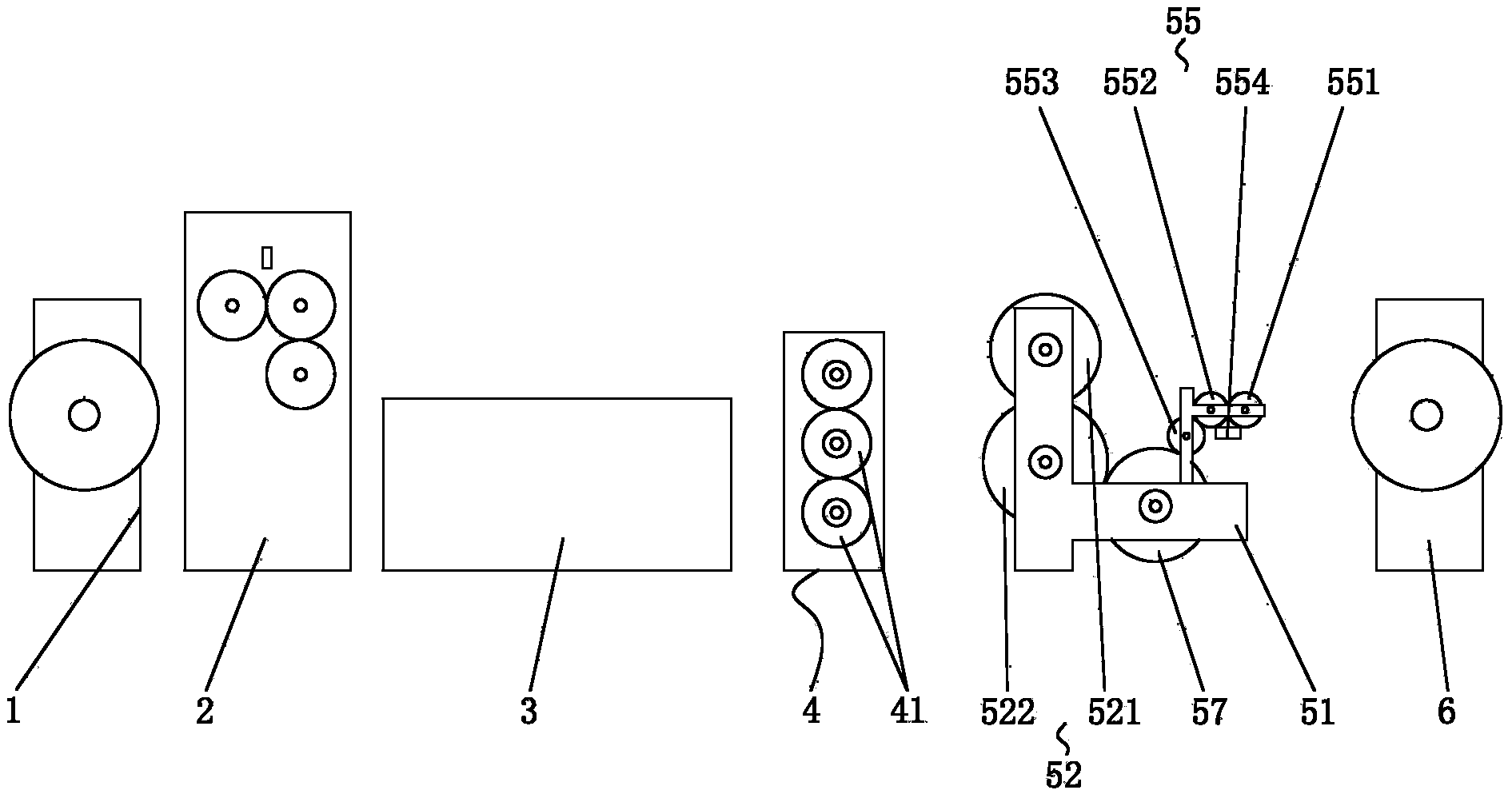

[0024] Embodiment 1: as figure 1 As shown, the non-woven fabric enters the coloring and embossing mechanism 5 after being glued, dried, and heated and flattened. On the surface of the roller 522, the color guide roller 57 is on the right side of the embossing roller 522, and the driving roller 521 is above the embossing roller 522. When the non-woven fabric flows to the gap between the embossing roller 522 and the driving roller 521, the embossing The roller 522 simultaneously colors and embosses the surface of the nonwoven fabric. When the color material transfer mechanism 55 does not transfer the color material to the embossing roller 522 surface, the color embossing mechanism 5 only embosses the surface of the non-woven fabric without coloring, and finally the non-woven fabric is collected by the winding mechanism 6 .

Embodiment 2

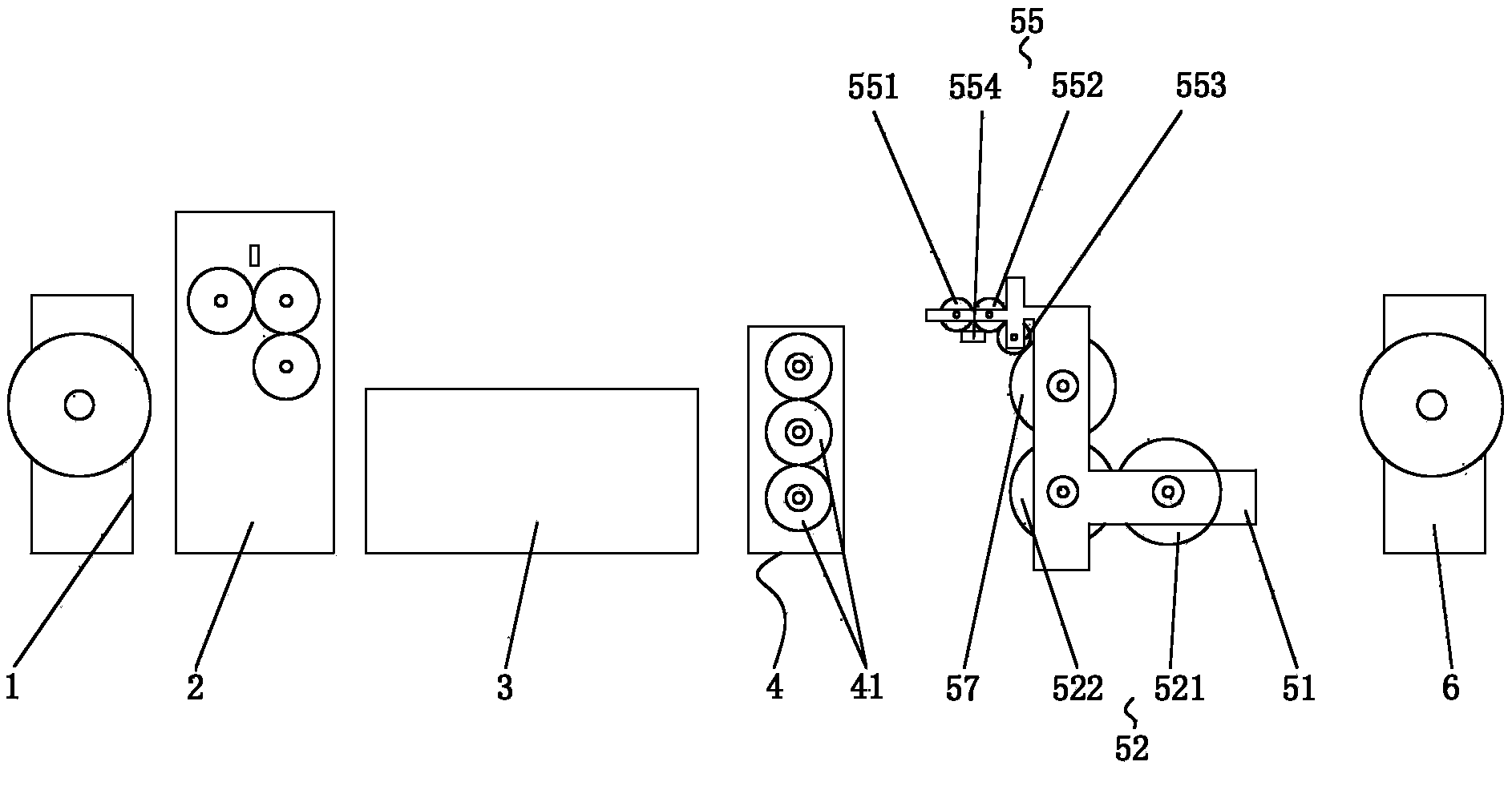

[0025] Embodiment 2: as figure 2 As shown, the working principle of embodiment 2 is the same as that of embodiment 1, the difference is that the color guide roller 57 is above the embossing roller 522 , and the driving roller 521 is on the right side of the embossing roller 522 .

Embodiment 3

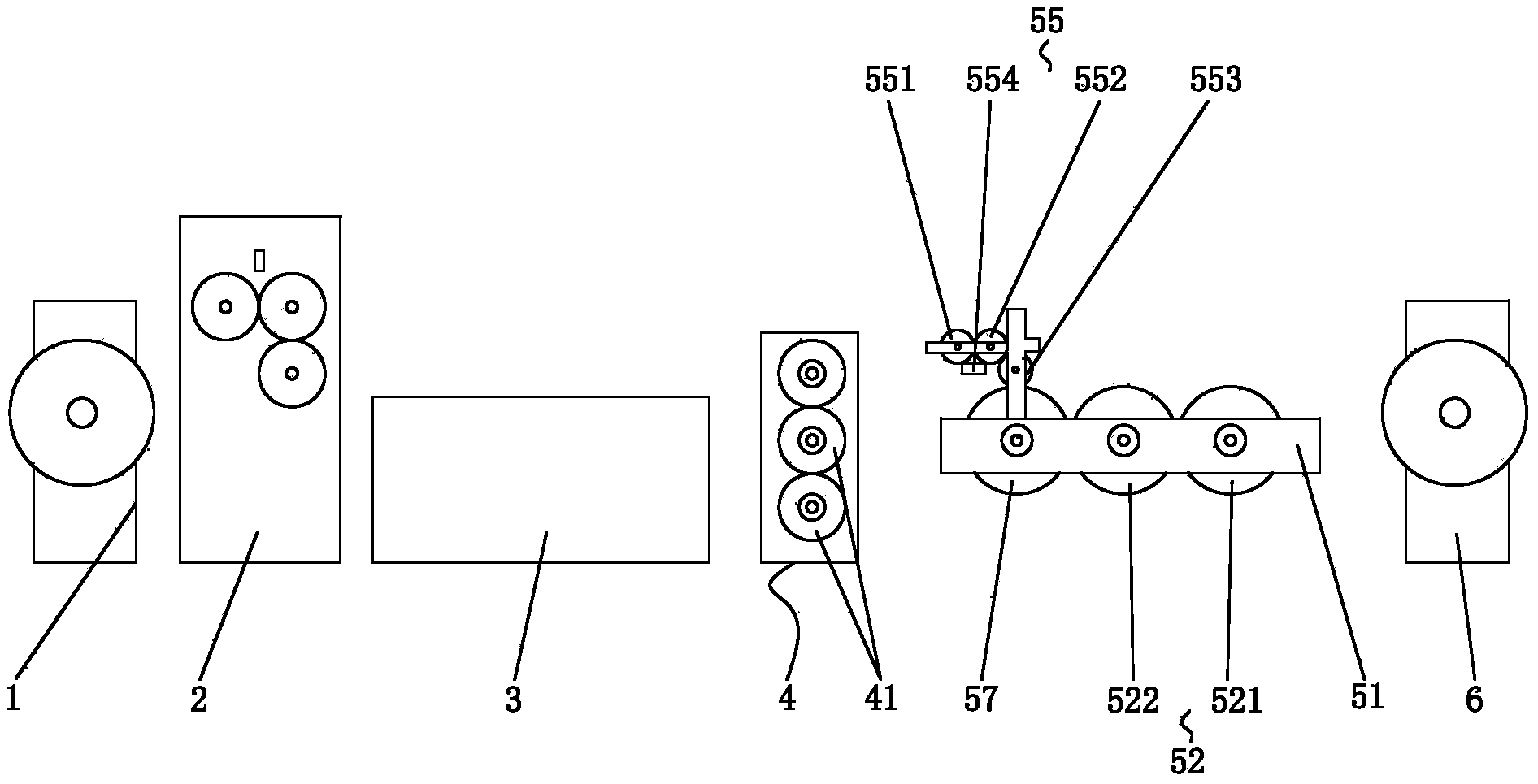

[0026] Embodiment 3: as image 3 As shown, the working principle of embodiment 3 is the same as that of embodiment 1, the difference is that the color guiding roller 57 is on the left side of the embossing roller 522 , and the driving roller 521 is on the right side of the embossing roller 522 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com