Crystallized glass and method for manufacturing same

A technology of crystallized glass and a manufacturing method, applied in the field of crystallized glass, can solve the problems of insufficient photocatalytic properties, high production cost, no crystal structure, etc., and achieve excellent photocatalytic activity, less performance degradation, and excellent durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21

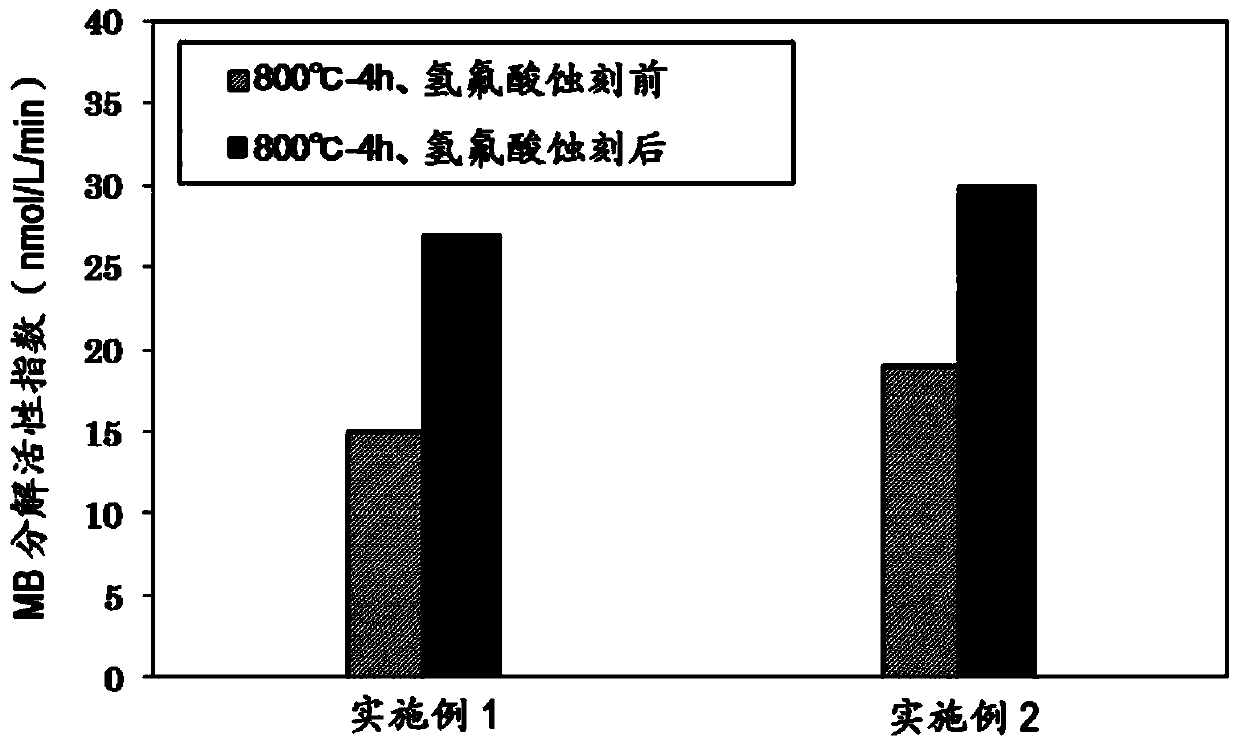

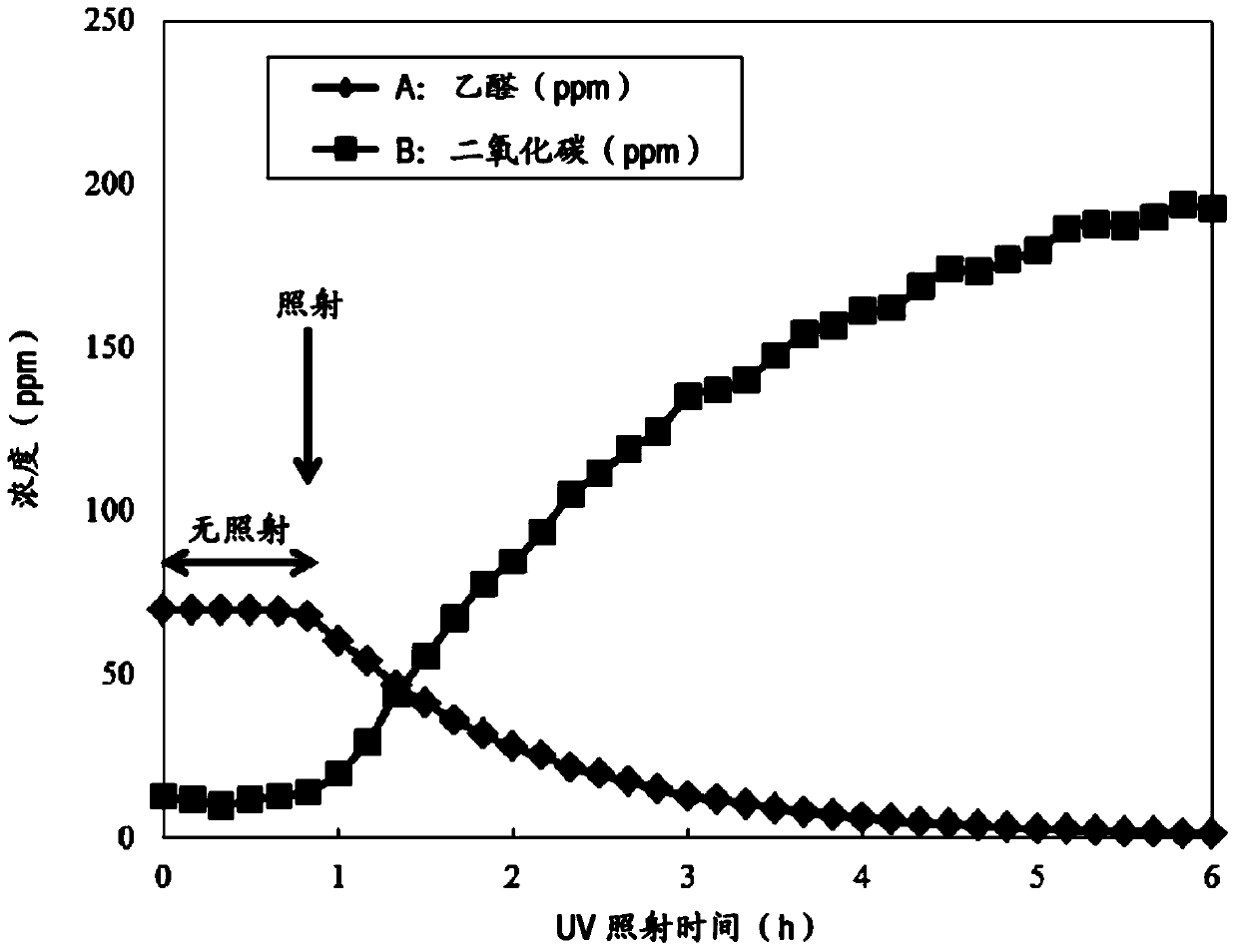

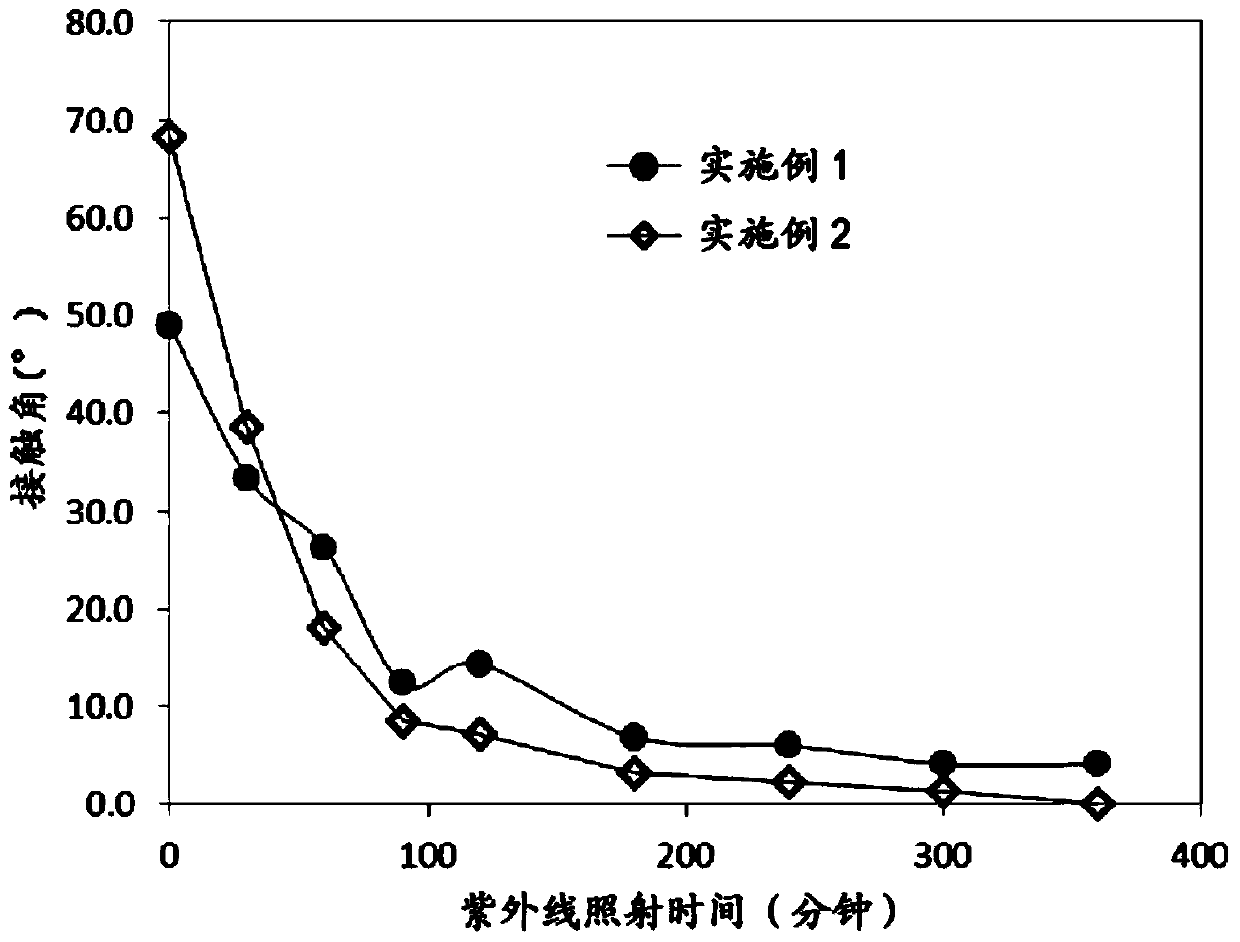

[0207] Tables 1 to 3 show glass compositions, heat treatment (crystallization) conditions of Examples 1 to 21 of the present invention, and decomposition activity indices of these crystallized glasses. The crystallized glasses of Examples 1 to 21 all select and use oxides, hydroxides, carbonates, nitrates, fluorides, chlorides, metaphosphoric acid compounds, etc., which are generally used in the high temperature of glass, as the raw materials of each component. Purity of raw materials. Weigh and mix these raw materials according to the composition ratio of each example shown in Table 1 to Table 3, and then put them into a platinum crucible. According to the melting difficulty of the glass composition, use an electric furnace at a temperature of 1200 ° C to 1600 ° C Melt within the range of 1 to 24 hours, stir evenly for defoaming, etc. The molten glass is then cast into molds and cooled slowly to make glass. The obtained glass was ground, heated to the crystallization temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com