Extraction method for yolk lecithin

A technology of egg yolk lecithin and an extraction method, which is applied in the field of extraction of egg yolk lecithin, can solve the problems of loss, complex extraction process and technology, high difficulty, etc., and achieves the effects of convenient operation, convenient acid value detection and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for extracting egg yolk lecithin, characterized in that the steps are as follows:

[0022] A. Egg yolk powder subjected to supercritical CO 2 Egg oil is removed by fluid extraction to obtain deoiled egg yolk powder;

[0023] B. the deoiled egg yolk powder is extracted with 80-100% ethanol solution, filtered to obtain an ethanol extract, and the solid content of the ethanol extract is measured;

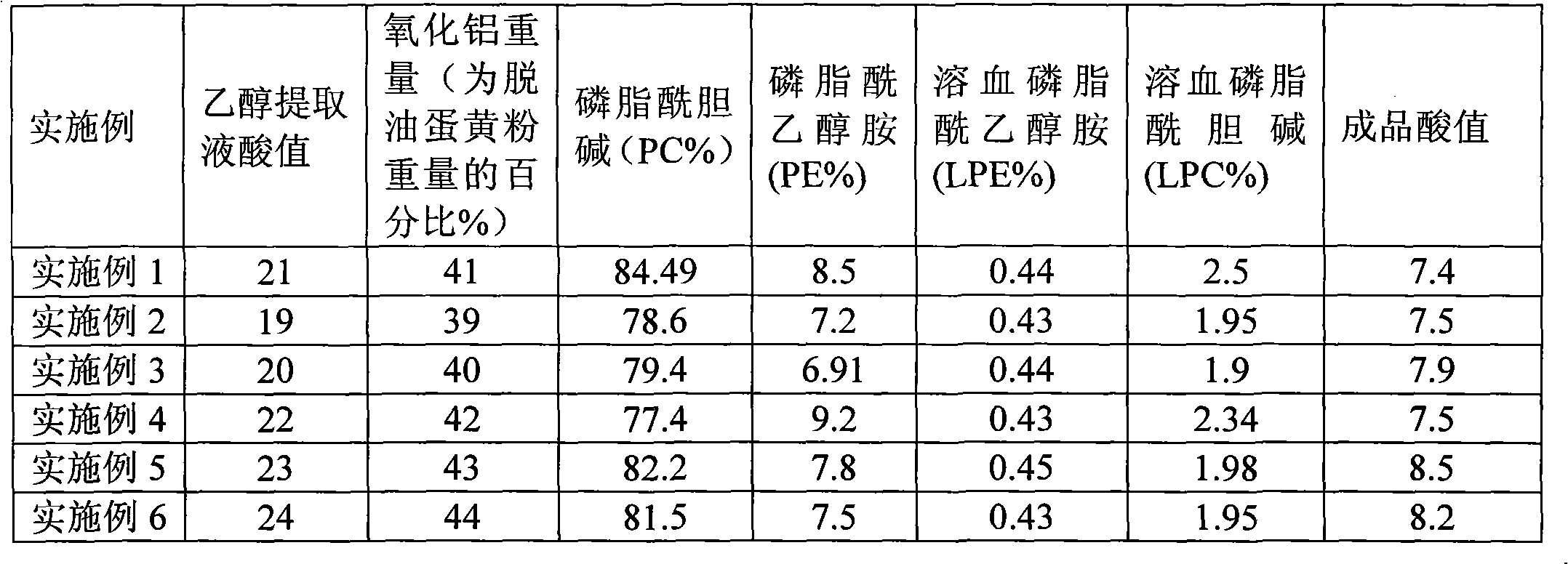

[0024] C. measure the acid value of the ethanol extract to be 21, add granularity in the ethanol extract obtained in step B and be that 100~200 mesh aluminum oxide is carried out adsorption treatment, and aluminum oxide weight is 41% of deoiled egg yolk powder weight;

[0025] D. The ethanol adsorption solution treated in step C is filtered and dried to obtain the finished egg yolk lecithin.

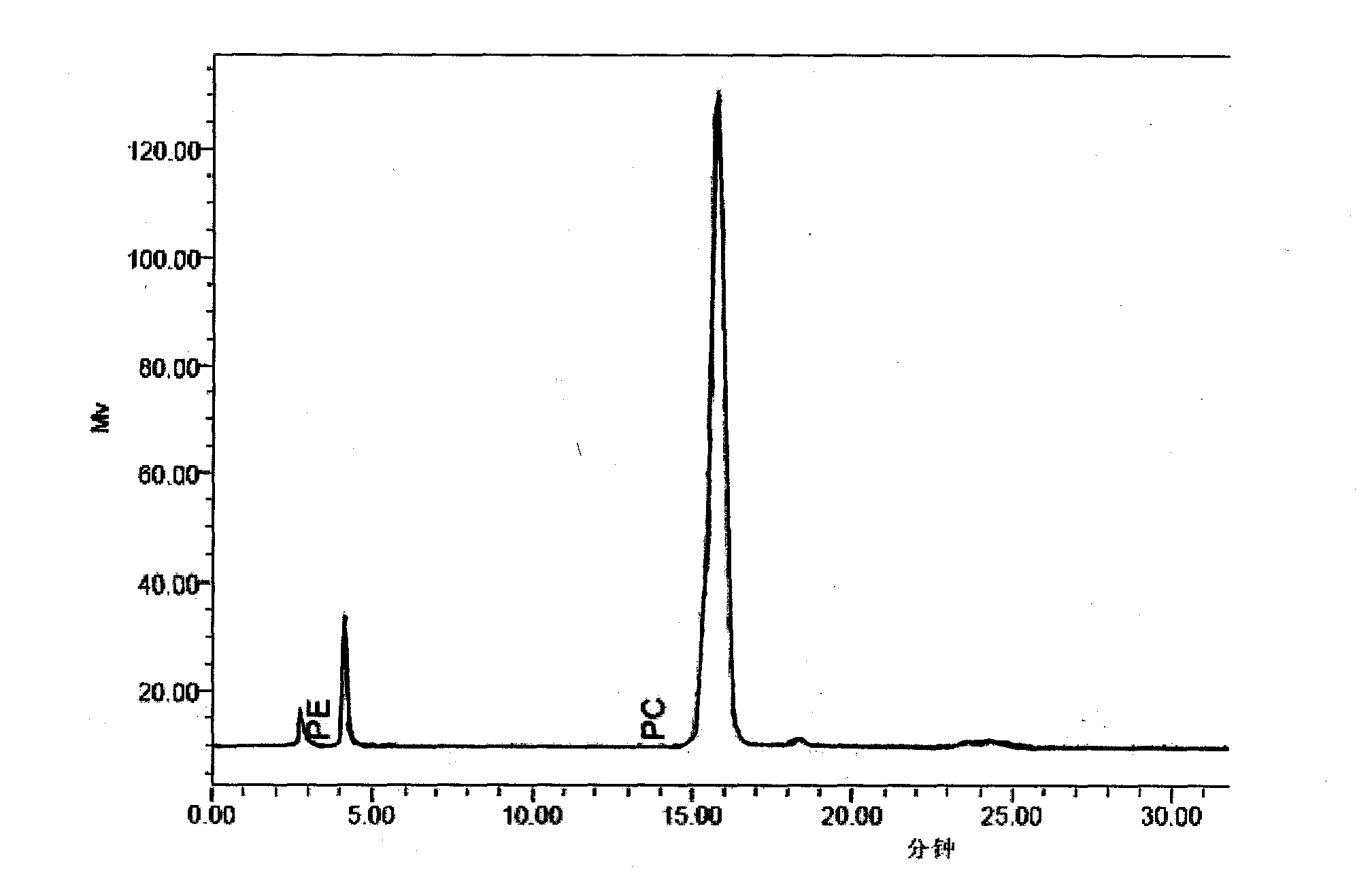

[0026] The obtained finished egg yolk lecithin has a content of 84.49% of phosphatidylcholine PC, 6.90% of phosphatidylethanolamine PE, 0.49% of lysophosphatidylethanolamine LPE...

Embodiment 2

[0028] Same as Example 1, the difference is:

[0029] In the step C, the acid value of the ethanol extract is 19, and the weight of aluminum oxide is 39% of the weight of deoiled egg yolk powder.

[0030] The obtained finished egg yolk lecithin has a PC content of 78.6%, a PE content of 7.2%, an LPE content of 0.43%, an LPC content of 1.95%, and an acid value of 7.5. All indicators are in line with the registration standard of refined egg yolk lecithin (YBF00022008).

Embodiment 3

[0032] Same as Example 1, the difference is:

[0033] In the step C, the acid value of the ethanol extract is 20, and the weight of aluminum oxide is 40% of the weight of deoiled egg yolk powder.

[0034] The obtained finished egg yolk lecithin has a PC content of 79.4%, a PE content of 6.91%, an LPE content of 0.44%, an LPC content of 1.9% and an acid value of 7.9. All indicators are in line with the registration standard of refined egg yolk lecithin (YBF00022008).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com