Al-Fe-Cu-Mg-Zn aluminum alloy for automobile wires and wire harness of Al-Fe-Cu-Mg-Zn aluminum alloy

An al-fe-cu-mg-zn, automotive wiring harness technology, applied in the field of aluminum alloys, can solve problems such as shedding, and achieve the effects of improving alloy strength, improving fatigue resistance, and overcoming processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An aluminum alloy for automotive wires, the components and weight percentages of each component are as follows (total weight: 1T):

[0042] components

Fe

Cu+Mg

Zn

Si

RE

Al

Weight (Kg)

2

0.1

0.01

/

/

997.89

Weight percentage (%)

0.2

0.01

0.001

/

/

99.789

[0043]In the above-mentioned aluminum alloy materials, it is preferable to add a certain amount of Zn. The addition of Zn will slightly reduce the electrical conductivity of the aluminum alloy, but can effectively improve the strength to a certain extent, and at the same time improve the creep rate of the conductor. It is preferable to add a certain amount of Cu, which has a certain solid solution strengthening effect, and the CuAl precipitated by aging 2 It has obvious aging strengthening effect, and the copper content in the alloy is most suitable at 0.01%-0.3%. If it exceeds this range, its aging strengthening effec...

Embodiment 2

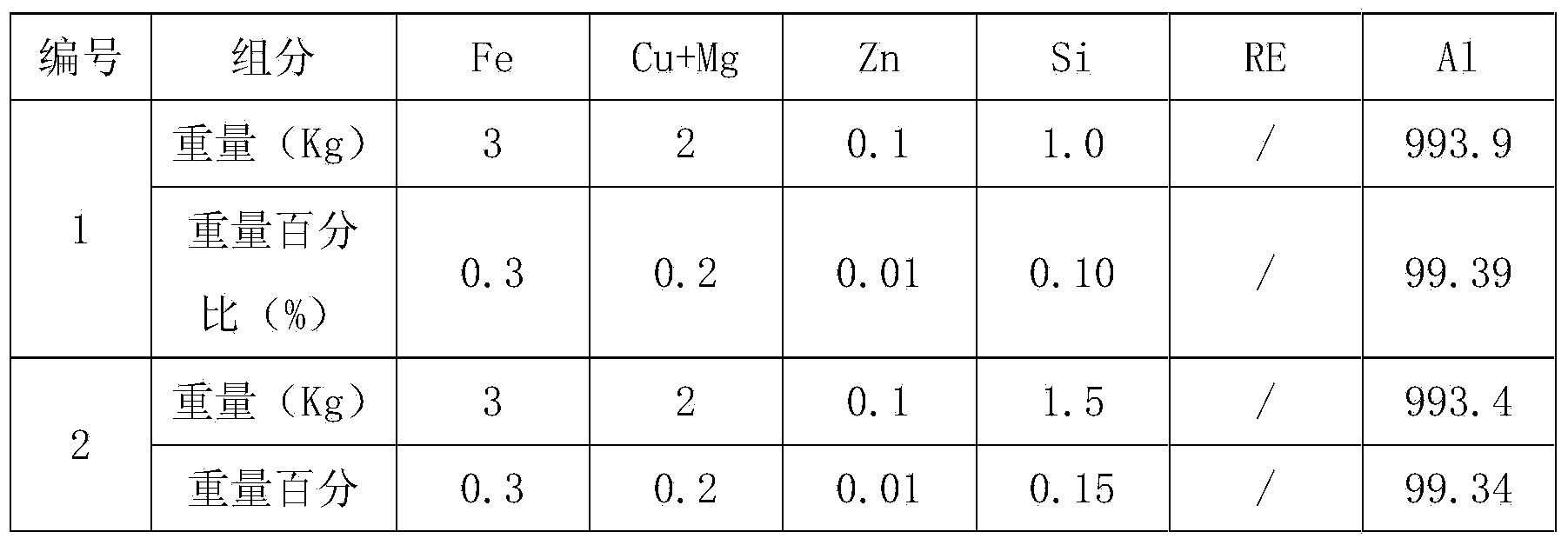

[0050] An aluminum alloy for automotive wires, the components and weight percentages of each component are as follows (total weight: 1T):

[0051]

[0052]

[0053] Among the above-mentioned aluminum alloy materials, the content of Si was compared. An appropriate amount of Si can increase the recrystallization temperature and refine the grains, while exceeding a certain content will reduce its electrical conductivity. In the process of implementation, it was found that the Si content Excessive samples are prone to breakage during the wire drawing process.

[0054] The method for preparing an aluminum alloy wire core by using the above-mentioned aluminum alloy material, the specific steps are as follows:

[0055] a. Melting and casting: add aluminum alloy components according to the above ratio, melt at 730°C, cast ingots at 670°C, and then roll into alloy rods after solution treatment and aging treatment. The aging treatment here is preferably at 140°C or at higher temp...

Embodiment 3

[0060] An aluminum alloy for automotive wires, the components and weight percentages of each component are as follows (total weight: 1T):

[0061] components

Fe

Cu+Mg

Zn

Si

RE

Al

Weight (Kg)

9.0

5.0

2.0

0.50

2.5

981.00

Weight percentage (%)

0.90

0.50

0.20

0.05

0.25

98.10

[0062] In the above-mentioned aluminum alloy materials, it is preferable to add a certain amount of RE elements, wherein Ce and La account for 50% of the total RE content, and rare earths can significantly improve the electrical properties of the alloy. In the present invention, rare earths are added to the aluminum alloy to make the aluminum alloy melt and cast Increase the supercooling of the composition, refine the grain, reduce the secondary grain distance, reduce the gas and inclusions in the alloy, and make the inclusion phase tend to be spheroidized. It can also reduce the surface tension of the melt,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com