Lattice type derrick of electric transmission line

A technology of transmission lines and lattice structure, which is applied in the field of transmission line lattice poles, which can solve the problems that FRP cannot be used for a long time at high temperature, the temperature resistance period is not long, and the performance is easy to decline, so as to facilitate transportation and use in mountainous areas , good water resistance, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

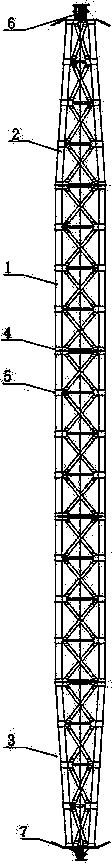

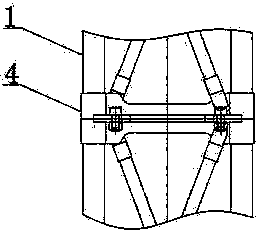

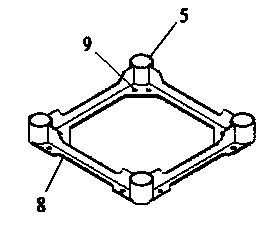

[0024] like figure 1 and figure 2 As shown, a transmission line lattice-type holding pole, the lattice-type holding pole is composed of a suspension base 7, a standard section 1 and a pulley 6 connected in sequence, and the two ends of the standard section 1 are provided with tapered end sections , the end section includes an upper end section 2 and a lower end section 3, the upper end section 2, the standard section 1, and the lower end section 3 are composed of a plurality of joint bodies, and adjacent joint bodies are connected by flanges 4, such as image 3 and Figure 4 As shown, the flange 4 includes a rectangular base 8 and intubation tubes 5 arranged at the four corners of the rectangular base. The intubation tubes 5 are preferably made of aluminum alloy. They are respectively inserted into the intubation tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com