Screw pump oil production real-time monitoring device

A real-time monitoring, screw pump technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problem that screw pump wells are difficult to diagnose accurately, and achieve intuitive test results, low test costs, fast and accurate testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

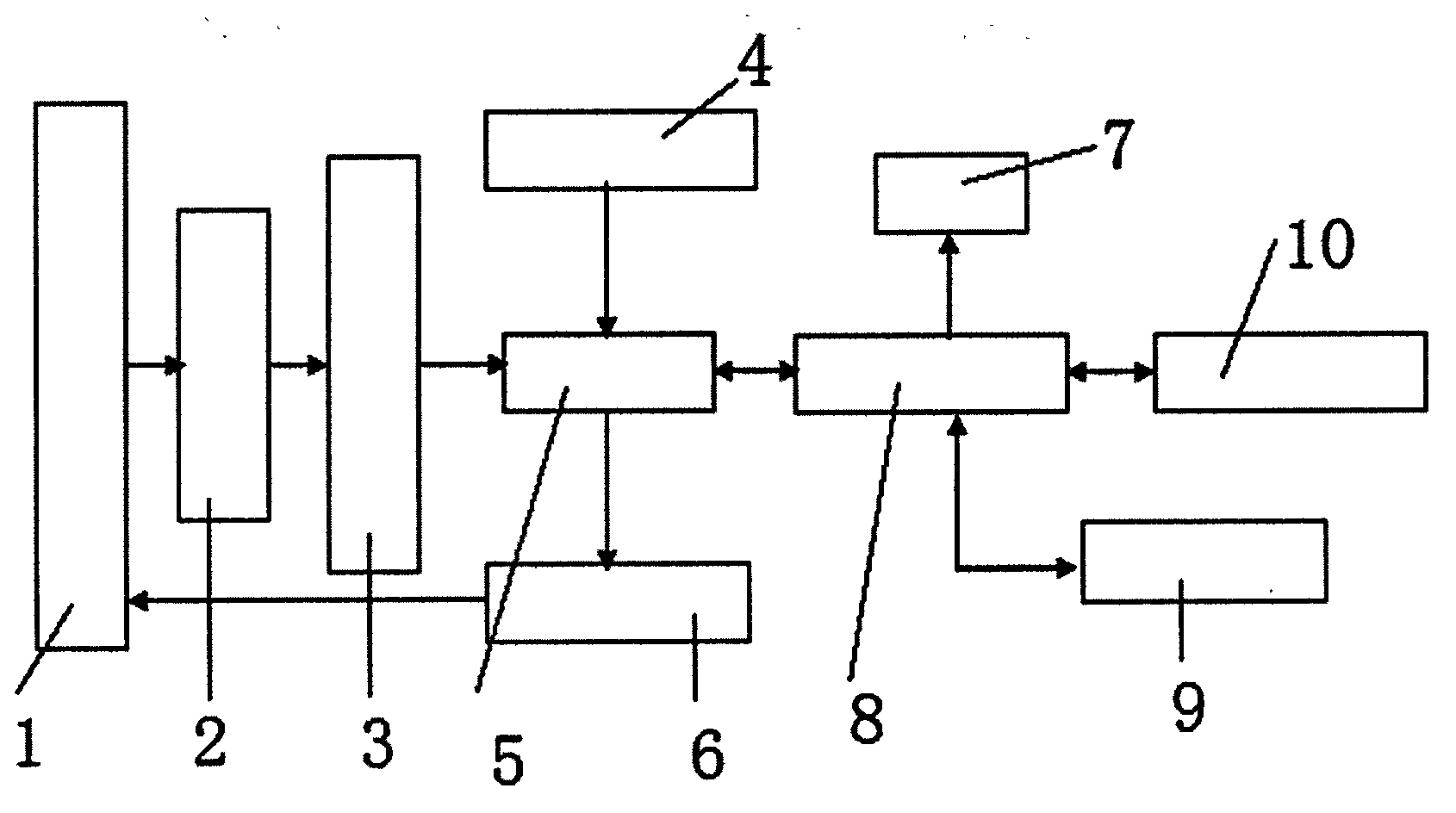

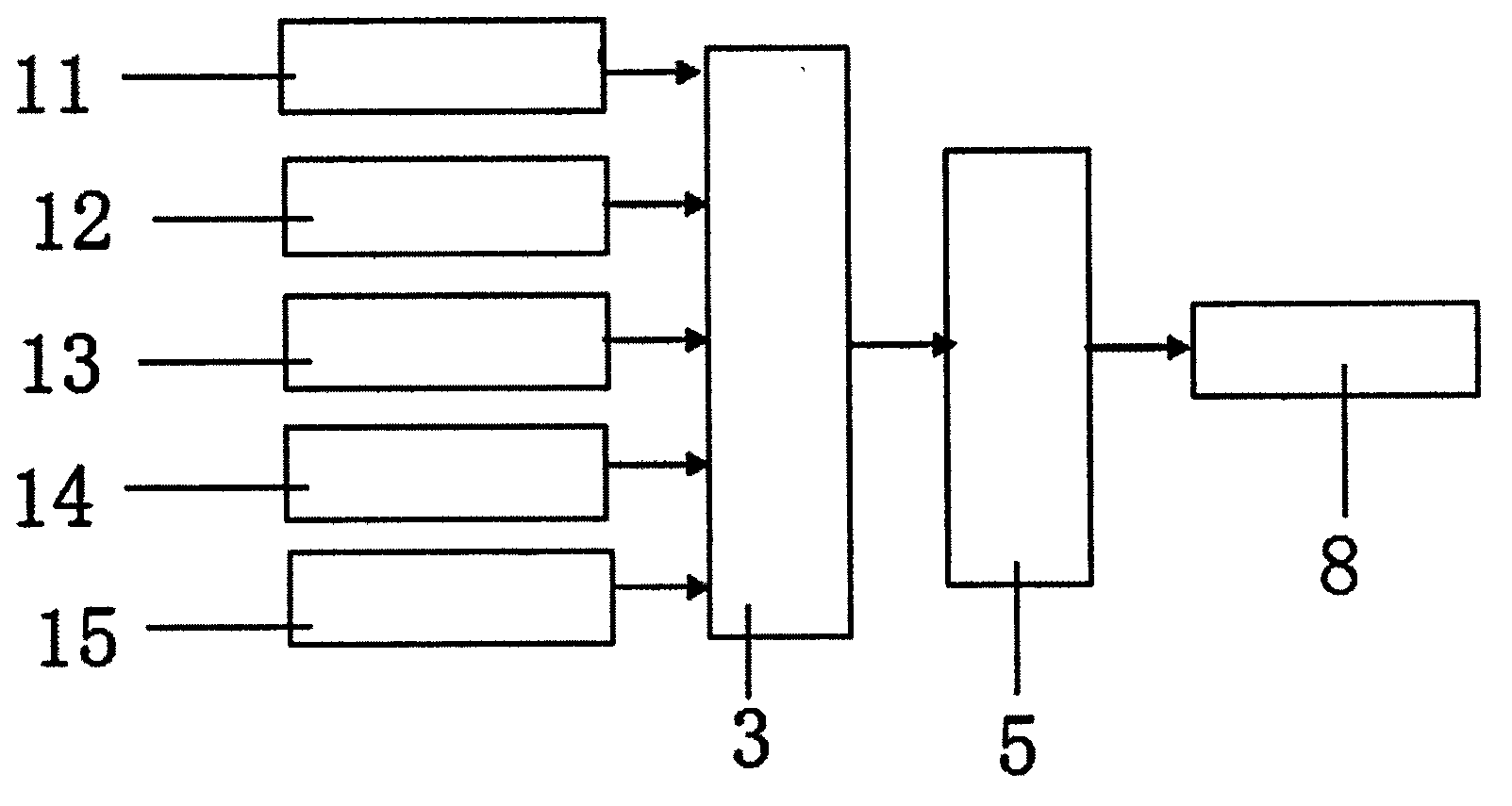

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] The sensor installed on the polished rod collects oil pressure, casing pressure, voltage, current, speed and torque signals, and converts them into weak voltage signals. The sensors all use bridge-type resistance strain gauge sensors, and the resistance values of the four resistors are equal to the working resistance. When working, the two pieces are under tension and pressure, which increases the sensitivity of the bridge to 4 times that of a single piece. Then, the preamplifier circuit properly amplifies, filters, and transforms the weak voltage signal collected by the sensor into a digital signal for transmission. microcontroller. These digital signals are processed by the single-chip microcomputer and then sent to the host computer for display, storage or printing. The screw pump 1 mentioned in the embodiment here can be a single-screw pump, a twin-screw pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com