A concentric circular corrugated solar cell silicon substrate and its manufacturing process

A solar cell and manufacturing process technology, applied in the field of solar cells, can solve the problems of large light reflection loss and lack of light concentrating performance, and achieve the effects of low production cost, prolonging effective power generation time, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

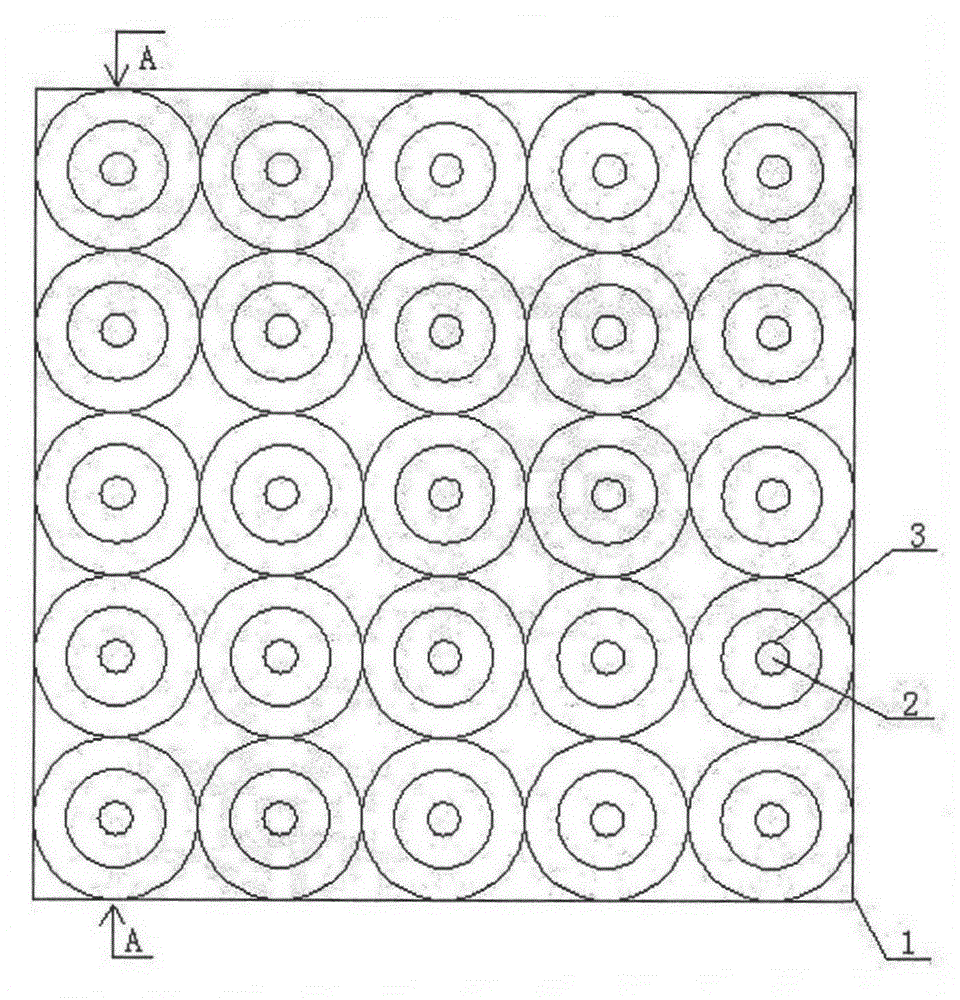

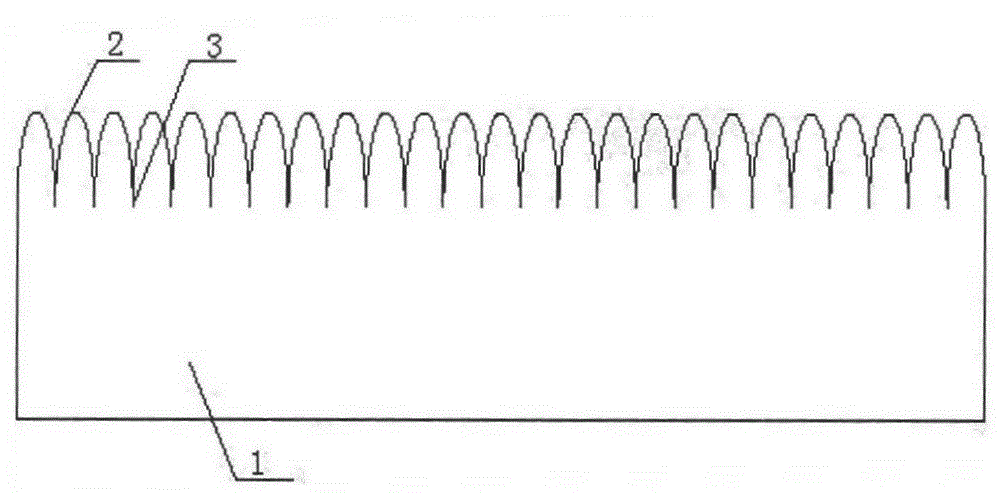

[0029] Such as figure 1 , 2 . As shown in 3, a concentric circular corrugated solar cell silicon substrate includes a silicon substrate body 1, and the surface of the silicon substrate body 1 is a concentric circular corrugated non-planar structure arranged sequentially in strips. The height difference between the top 2 and the bottom 3 of the concentric circles of the silicon substrate body 1 is in the range of 2-3 mm. The width difference between the diameters of the bottom surfaces of the concentric circles of the silicon substrate body 1 is in the range of 7-12 mm.

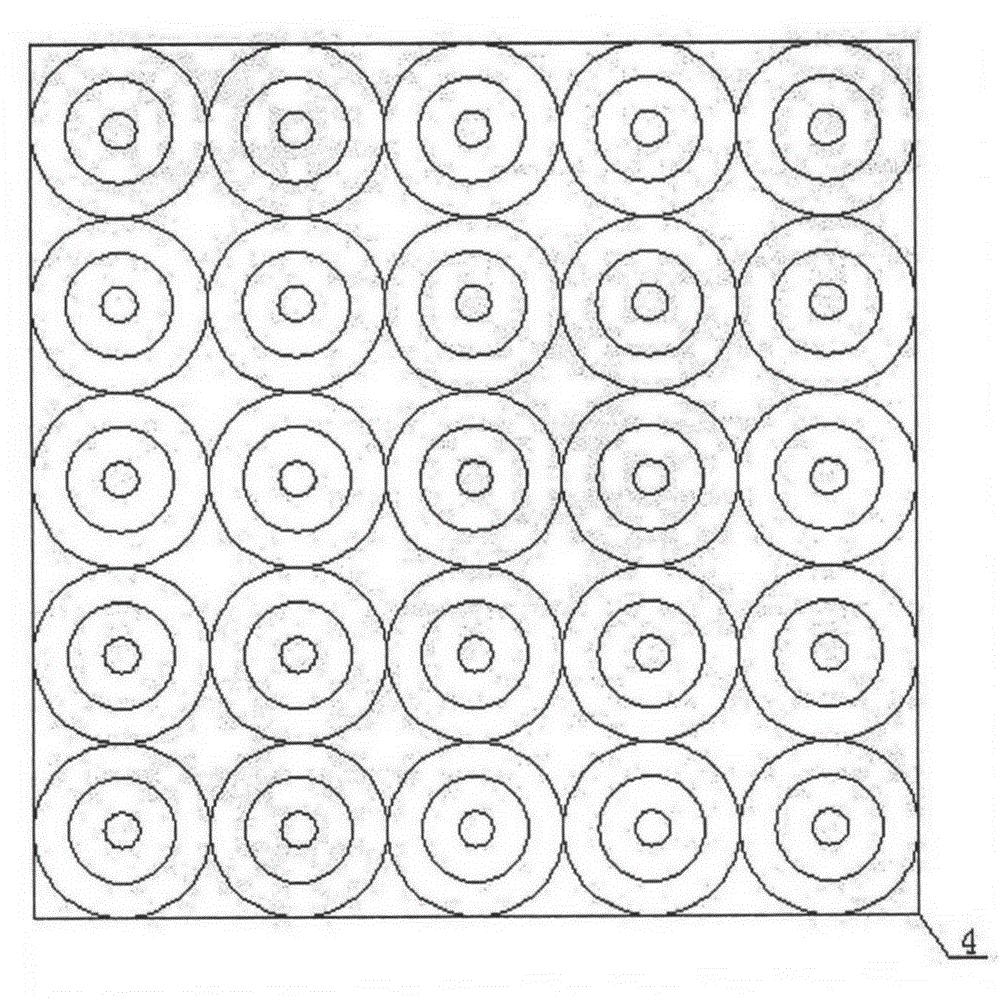

[0030] Such as Figure 4 Shown, a kind of manufacturing process of concentric circular corrugated solar cell silicon substrate comprises the following steps:

[0031] Step 1, oxidation masking layer deposition: Utilize the silk screen 4 that has the concentric circular window arranged in strip order to deposit the silicon dioxide oxide layer on the silicon substrate, form the two layers with concentric circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com