Cooperative control method for unmanned aerial vehicle power line routing inspection

A power line and collaborative control technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of lack of overall system design, synchronization, complex working mode, lack of connection, etc., and achieve the effect of improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

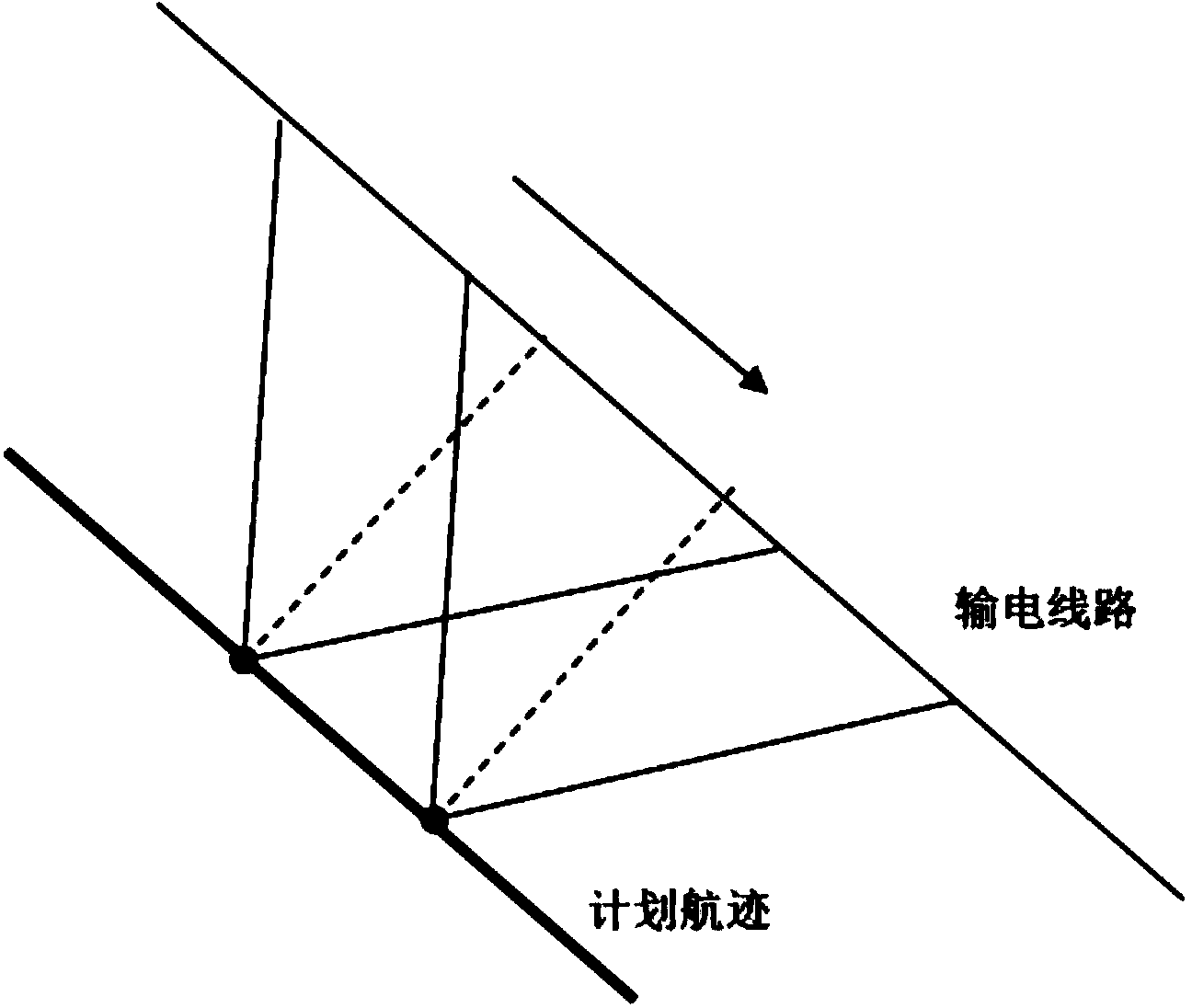

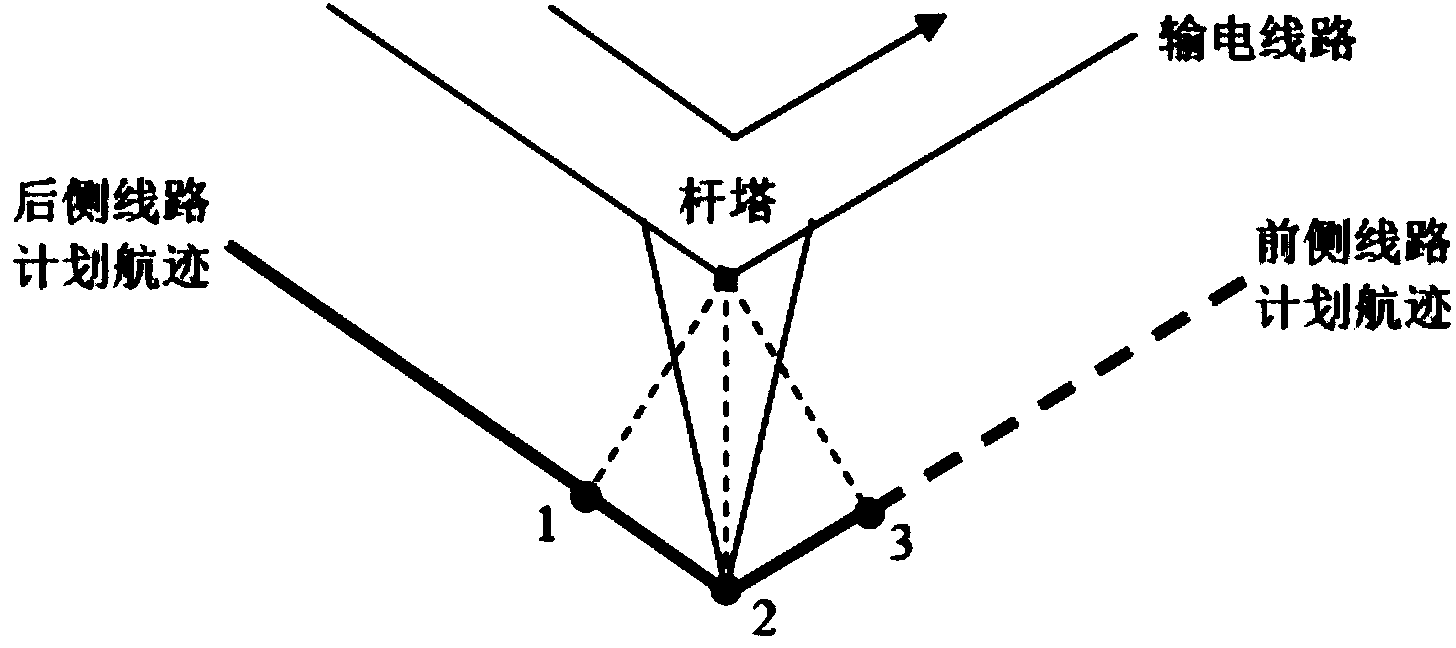

[0037] In order to further illustrate the technical means adopted by the present invention and the achieved effects, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and preferred embodiments.

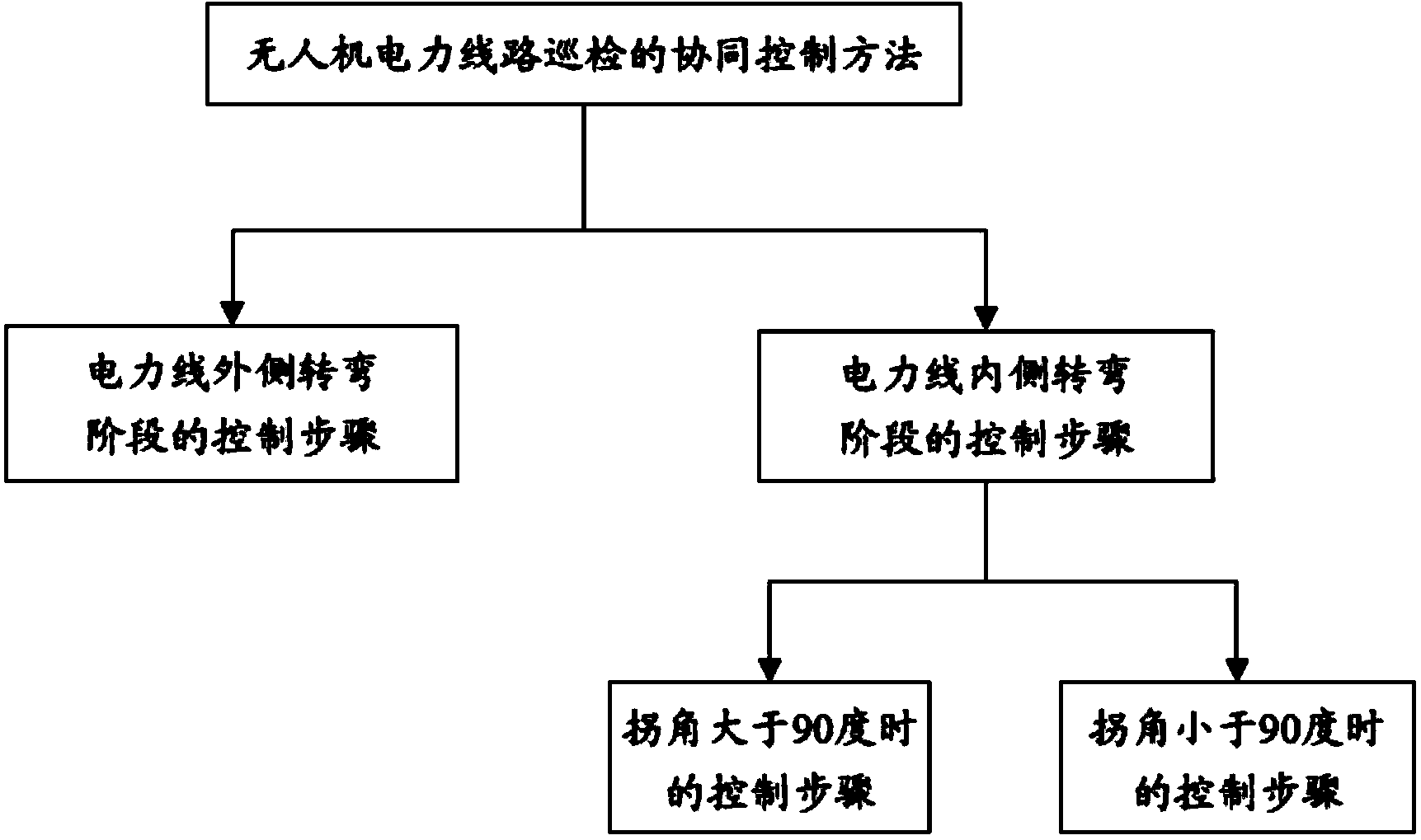

[0038] see figure 1 , is a schematic flow chart of the cooperative control method of the UAV power line inspection of the present invention.

[0039] The cooperative control method of the UAV power line inspection of the present invention includes the control steps of the power line outer turning stage and the power line inner turning stage in the UAV power line inspection;

[0040] Wherein, the control steps of the outer turning stage of the power line include:

[0041] When the UAV flies to the preset hovering position, the tower is photographed sequentially through the short-focus camera and the long-focus camera;

[0042] After shooting the tower, start the locking mode of the UAV stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com