An automatic pancake machine

A pancake machine and pancake technology, which is applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problems that the toughness and taste of pancakes cannot be guaranteed, the difficulty of scraping pancakes to adjust, and the viscosity cannot be spread, etc., so as to avoid scraper damage, The effect of high degree of automation and guaranteed integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

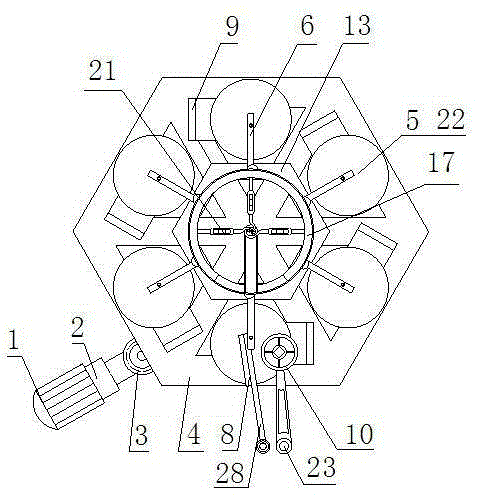

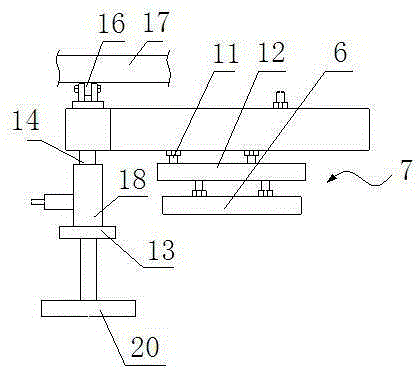

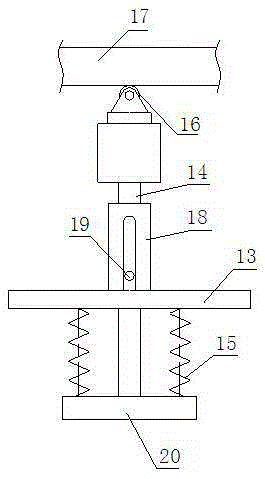

[0022] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. This automatic pancake machine includes a power unit, an oil rubbing device, a pancake spreading device, a heating and baking device, a pancake scraping device and a pancake output device, etc. The core of the machine is a pancake spreading device and a heating and baking device, and other parts It can be installed directly, and some actions can also be done manually.

[0023] This pancake machine is a disc-shaped pancake machine as a whole, and what plays the role of this machine frame is a turntable, and the turntable is made up of a bottom turntable 4 and an intermediate turntable 13 fixed together. In this embodiment, the turntables are all regular hexagons, and 6 grid plates are installed correspondingly. Of course, the turntable can also be changed into regular polygons with other numbers of sides, and corresponding grid plates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com