A processing method of a crescent groove of aero-engine valve shell

A technology of aero-engine and processing method, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high dimensional accuracy of parts, low pass rate of tiny precision parts such as nozzles, and difficulty in clamping parts, etc., to achieve improved The effect of batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0020] See attached Figure 2-6 As shown, the steps of the processing method of this kind of aero-engine valve housing crescent groove are:

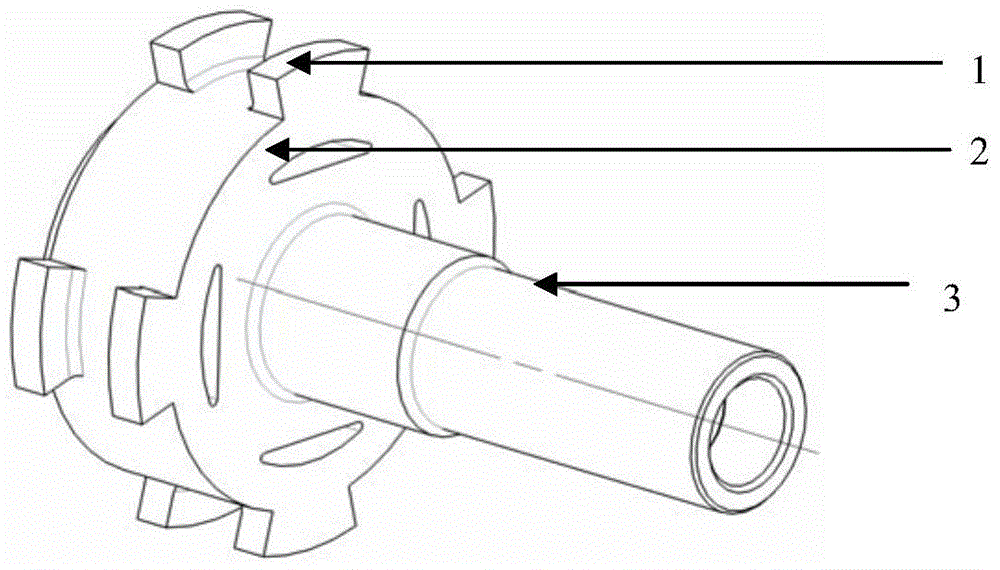

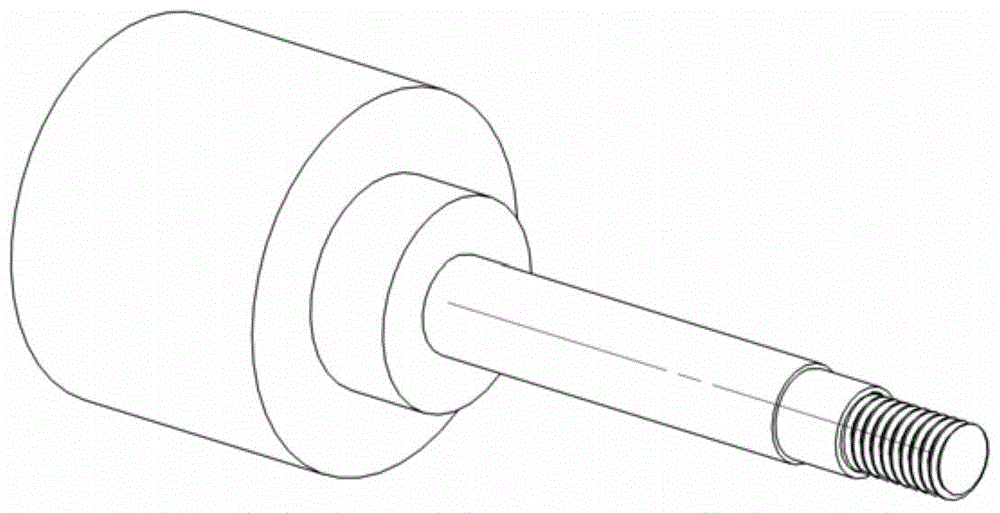

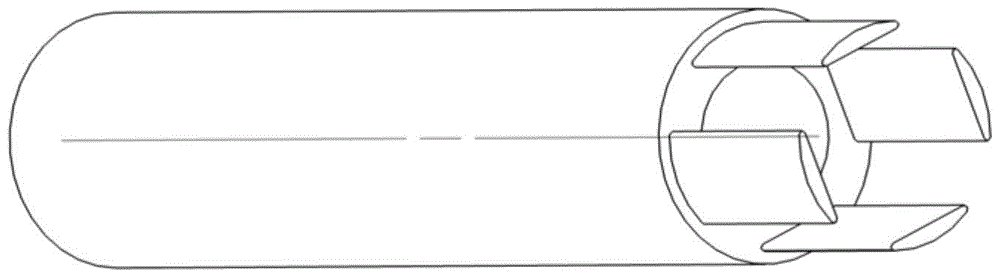

[0021] (1) A crescent-shaped electrode fixture 5 is installed on the basic fixture 10 of the DMU60P CNC machine tool, and the bar material 11 for processing the crescent-shaped electrode 4 is clamped by the crescent-shaped electrode fixture 5. The indication value of the sub-meter is <0.002mm. Four evenly distributed crescent-shaped electrodes 4 are formed and processed on the bar 11 at one time, and the position and shape of the crescent-shaped electrodes 4 coincide with the four evenly distributed crescent grooves 2 on the valve housing 7 .

[0022] (2) After the crescent-shaped electrode 4 is processed, install the crescent-shaped electrode fixture 5 together with the crescent-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com