Metal shell soldering method

A metal shell and soldering technology, used in metal processing, metal processing equipment, welding equipment, etc., can solve problems such as affecting product performance, inability to do anything about double-sided printed boards, and inability to reserve screw holes, and achieve good grounding effect. , The effect of good impact resistance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

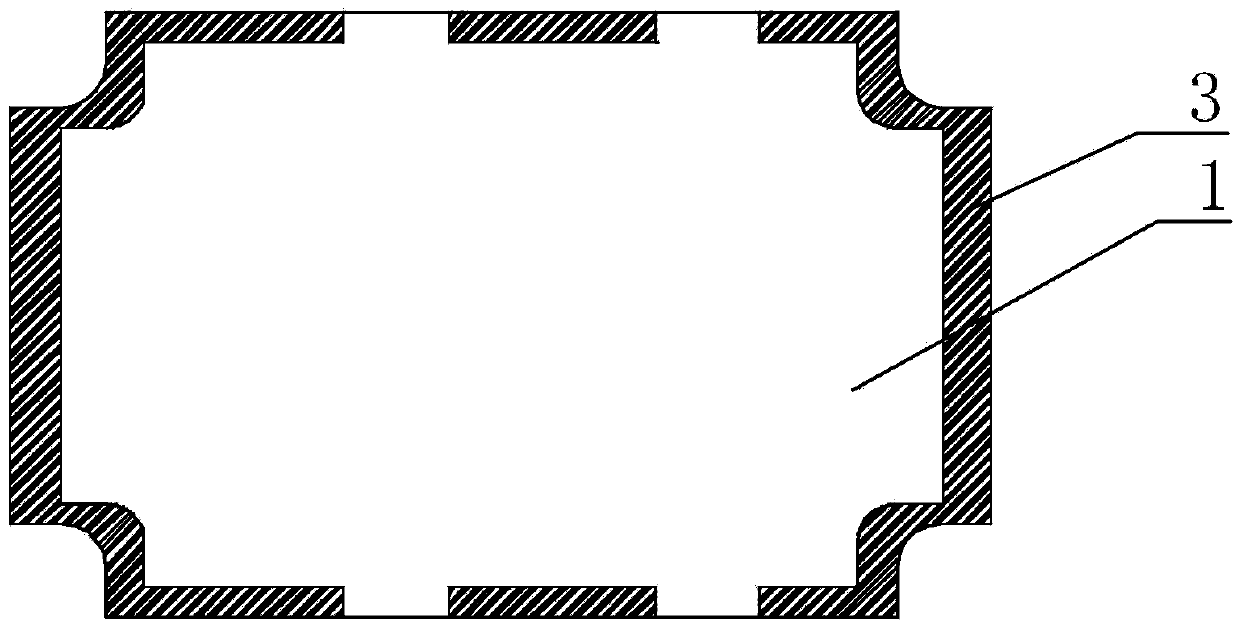

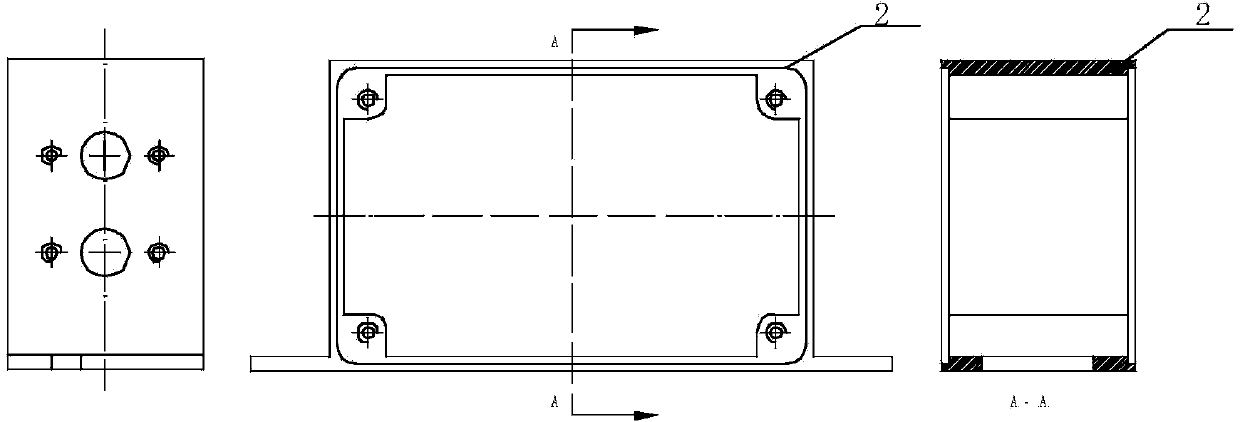

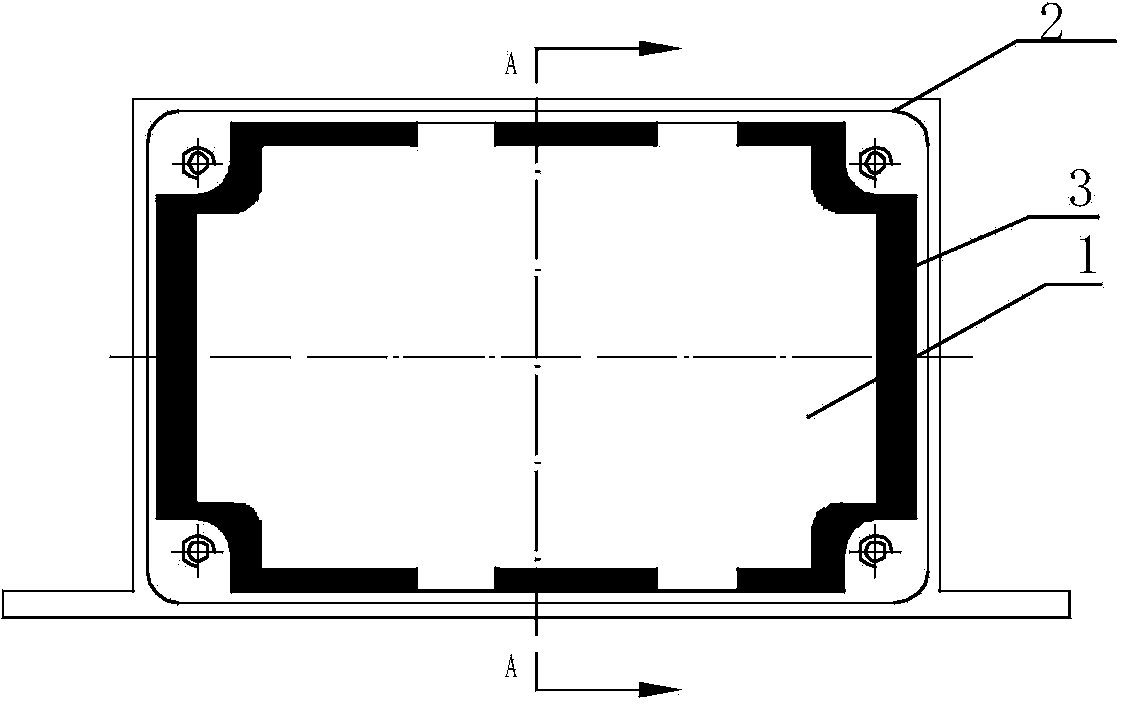

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] As shown in the accompanying drawings, a metal shell soldering method is:

[0041] Step 1: Fixing, position the printed board 1 in the box body 2, and initially fix the printed board 1 and the box body 2 with solder; there are grounding holes around the printed board;

[0042] Step 2: Preheat

[0043] Place the fixed printed board and box body on a temperature-controlled heating table for preheating. The preheating temperature is between 130°C and 180°C, and the preheating time is not less than 3 minutes.

[0044] Step 3: Apply Rosin Flux

[0045] Apply rosin flux to the solder joints;

[0046] Step 4: Soldering

[0047] Adjust the temperature-adjustable soldering iron to 300°C to 380°C, wipe the tip of the soldering iron with wet foam cotton, and apply an appropriate amount of solder (until the solder does not fall off), and the tip of the soldering iron is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com