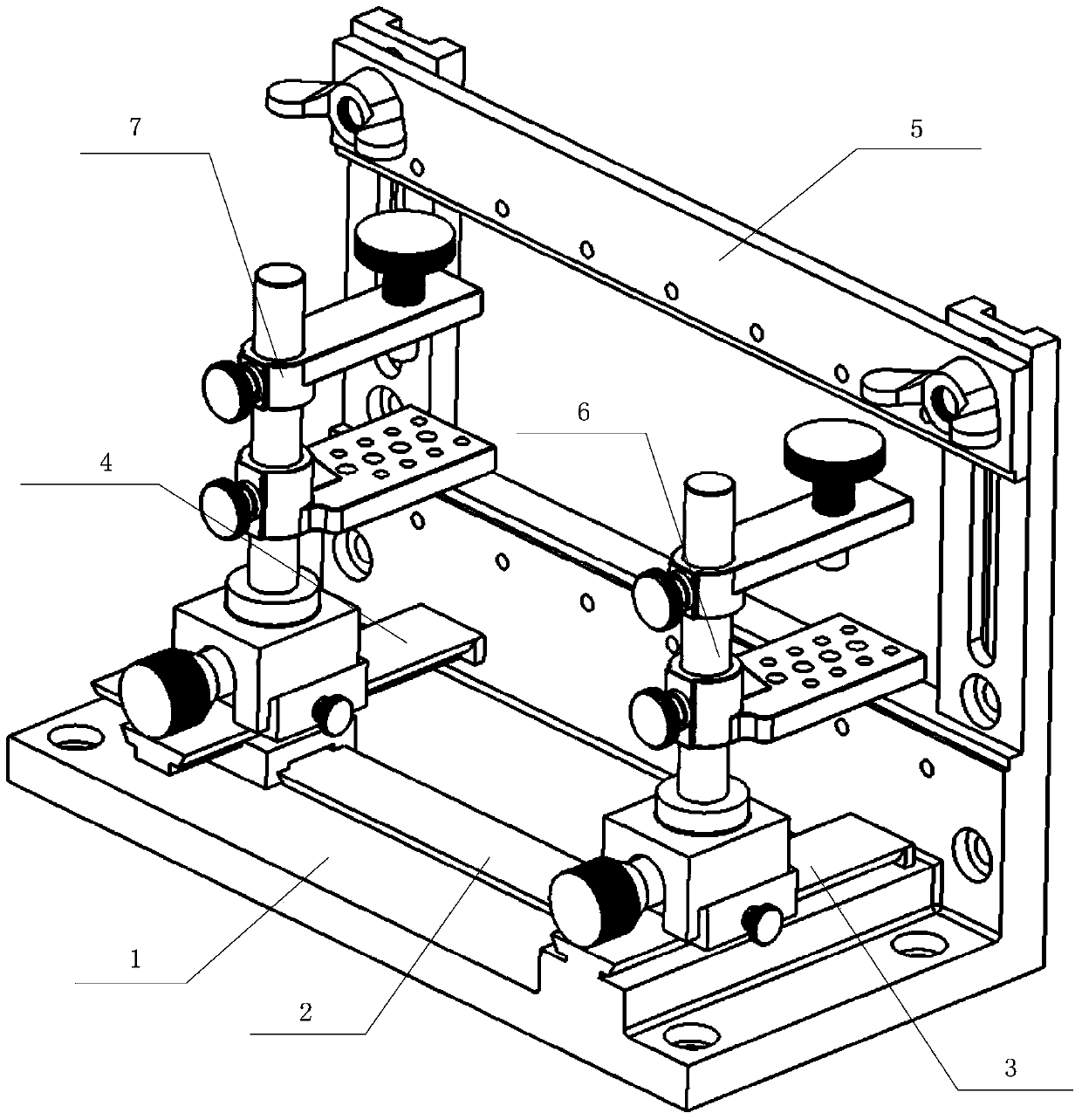

Optical waveguide parameter testing clamp

A parametric testing and optical waveguide technology, applied in the field of optical waveguides, can solve the problems of increasing test difficulty and detector requirements, inability to adjust the gap between the bottom surfaces of prisms, low coupling efficiency of optical waveguides, etc., to achieve reliable transmission loss, simple structure, test high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

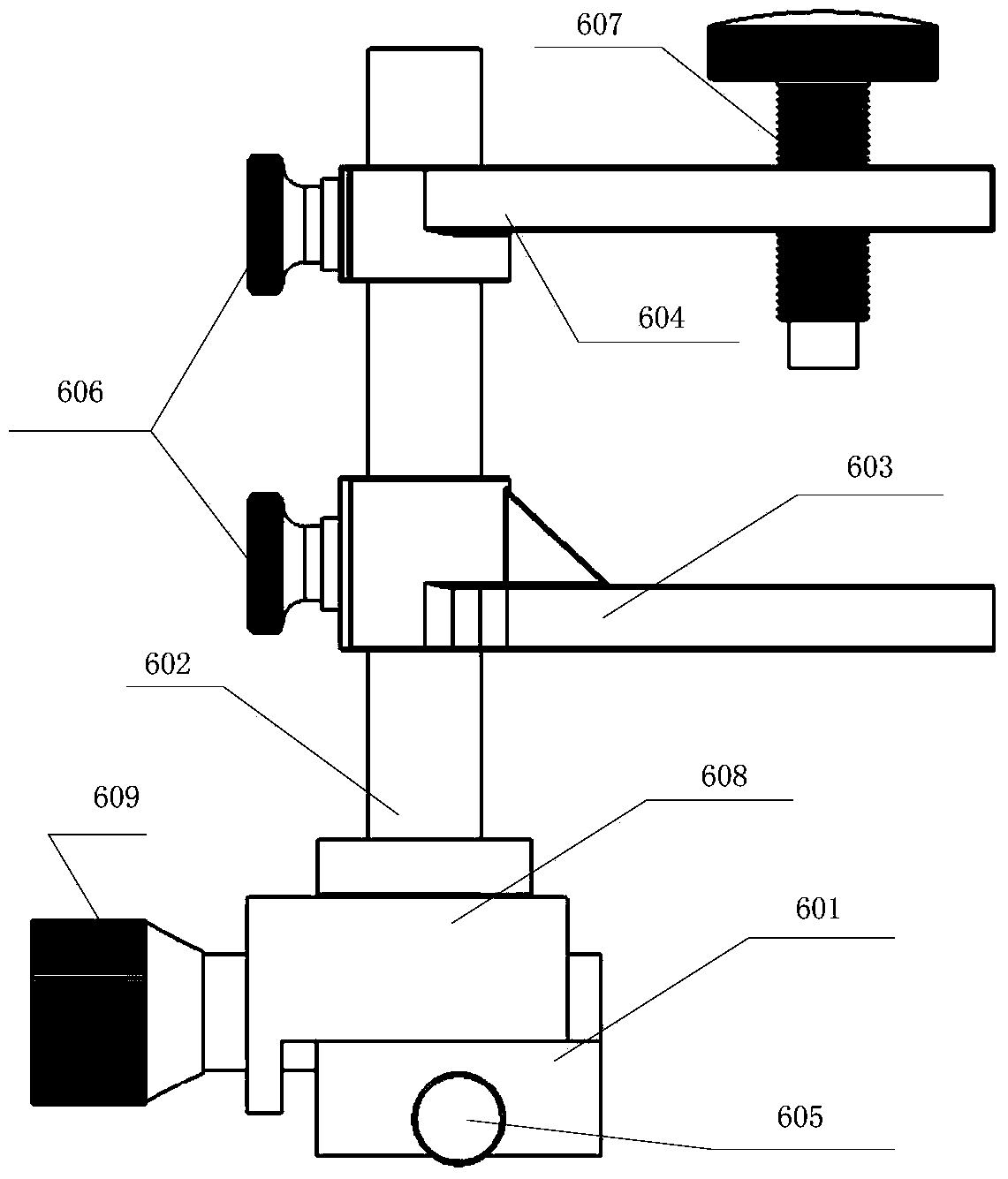

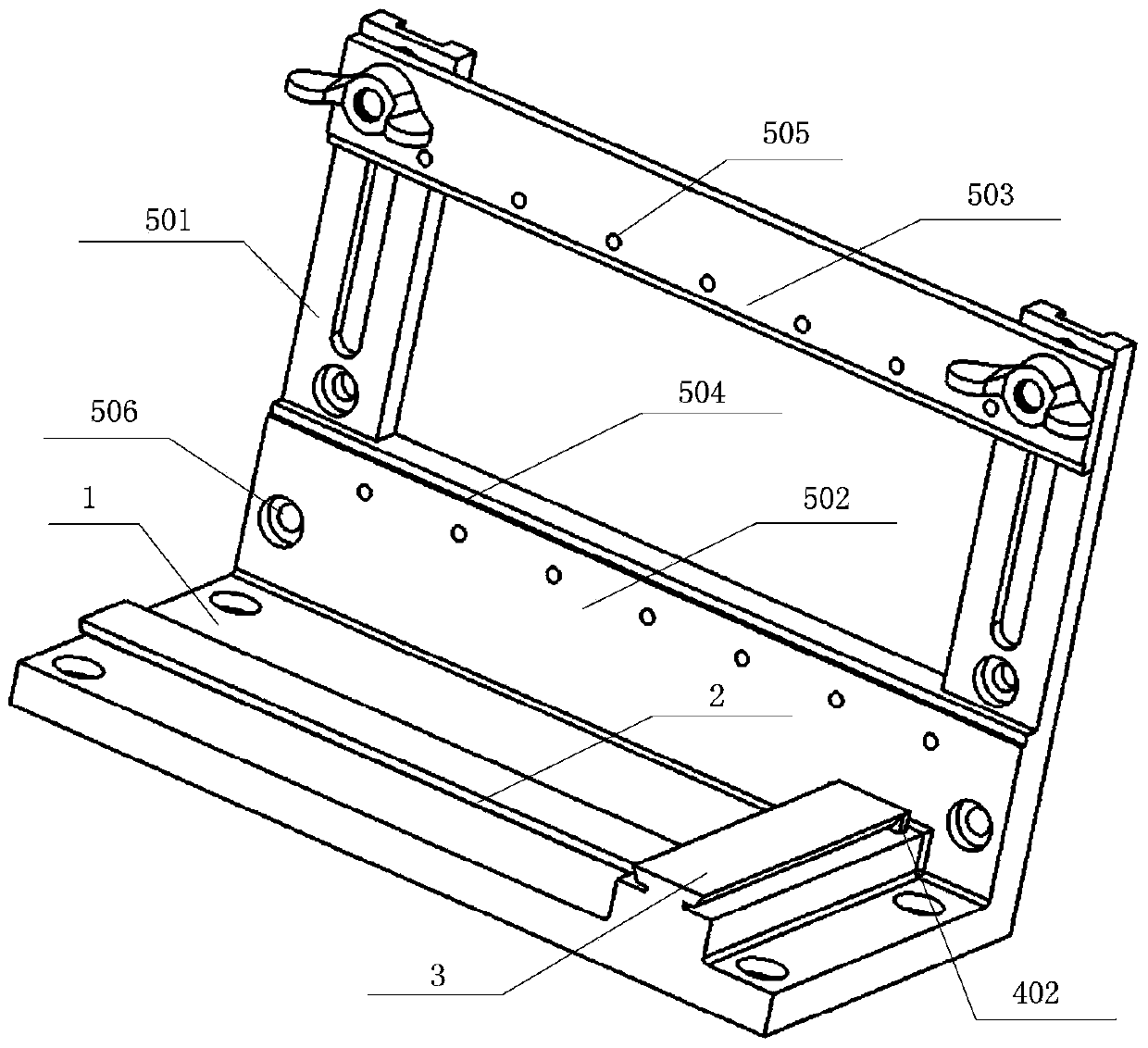

example 1

[0059] Stainless steel or aluminum alloy is selected as the manufacturing material, and standard parts such as set screws, lag screws and wing nuts are selected. The base is L-shaped, 120mm long, 60mm wide, 8mm thick, and 24mm high. The length of the longitudinal guide rail 2 is 90mm, the length of the fixed transverse guide rail 3 and the sliding transverse guide rail 4 are both 48mm, and the plane of the guide rail after the longitudinal guide rail 2 of the sliding transverse guide rail 4 is on the longitudinal guide rail 2 coincides with the plane of the fixed transverse guide rail 3. The vertical slide rail 501 of the optical waveguide fixture 5 has a length of 54 mm, a width of 15 mm, and a thickness of 5 mm. The sliding support plate 503 is 120mm long, 15mm wide and 3mm thick. The threaded holes on the fixed support plate 502 and the sliding support plate 503 are M5, and the limit steps are 2mm×0.5mm. The size of the prism is 20mm×20mm×20mm, and the optical waveguide t...

example 2

[0062] The optical waveguide loss is measured by CCD digital photography. Remove the output prism fixture 7, and excite the optical waveguide light by retaining the prism coupler clamped by the input prism fixture 6. The schematic diagram of the test principle is as follows Figure 6 shown. After using the image acquisition card to collect the light intensity data reflected in the photos taken by the CCD camera 8, digital image processing technology is used to filter and reduce noise, and the transmission light intensity change graph of the optical waveguide light in the optical waveguide layer can also be drawn, so as to obtain The transmission loss of the optical waveguide to be measured is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com