Sealing valve discharge method and discharge device using same

A technology of valves and pressing devices, which is applied in the direction of transportation and packaging, conveyors, rotary conveyors, etc., can solve the problems of large particle material jamming, large particle material bridging, screw ash discharge valve leakage, etc., to achieve unloading Smooth ash, smooth nesting, and solve the stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

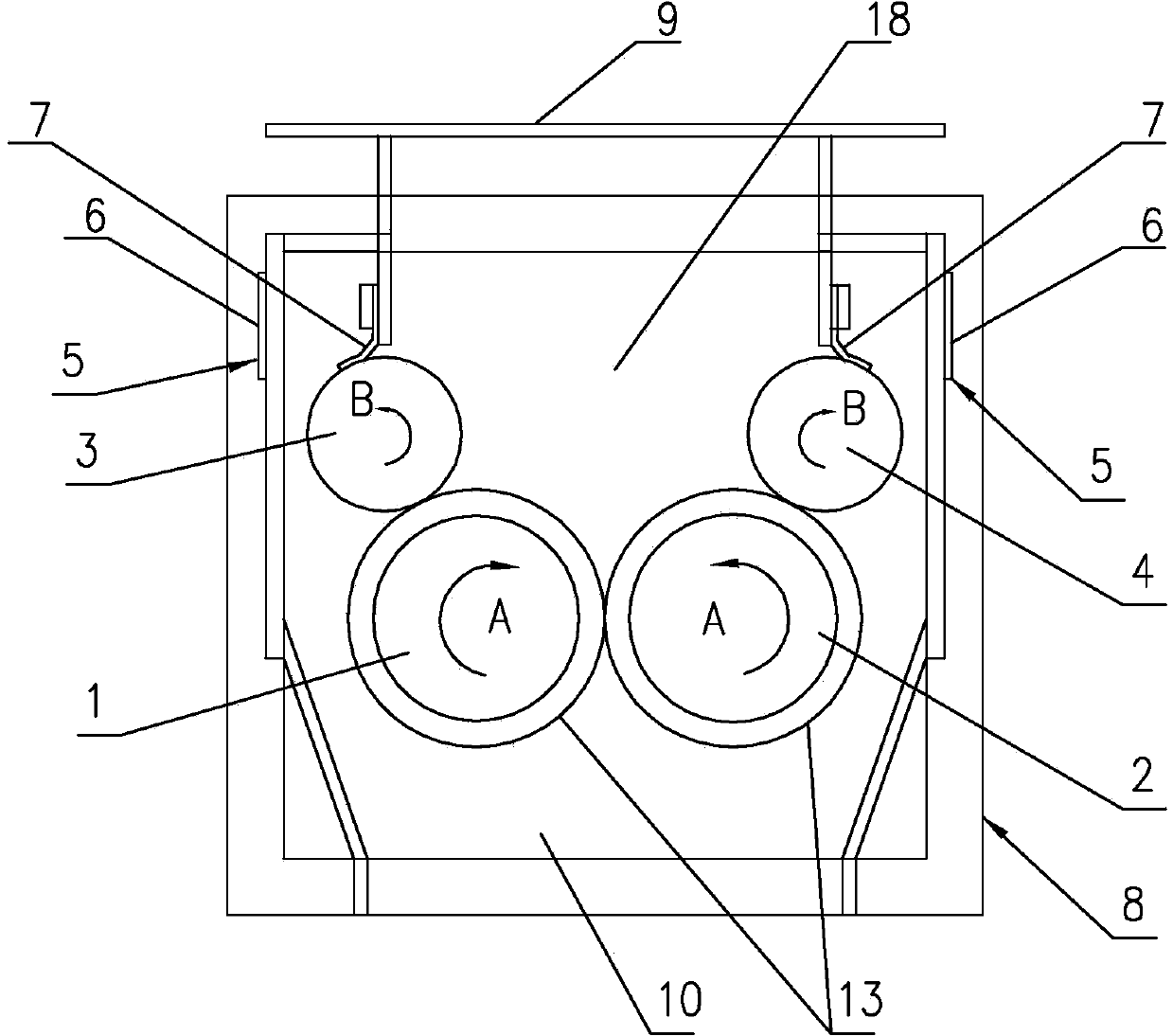

[0045] It is a sealing valve discharge method of the present invention. In an installation space, a pair of rollers arranged side by side, pressed against each other and capable of rotating inwardly in reverse are arranged. The rollers and the installation space form a closed space, and the outer wall of the rollers is wrapped Covered with elastic and wear-resistant lagging, the lagging on the two rollers is close to each other, and the material is squeezed out from the discharge space between the lagging on the two rollers, and the discharge space is squeezed by the elastic rubber on the roller. The lagging is formed by extrusion. When the material is squeezed by the elastic lagging on the two rollers, the lagging will release space for the material to be discharged under the action of elasticity. After the material is discharged, the lagging will remain in close contact under the action of elasticity to ensure no Air leak.

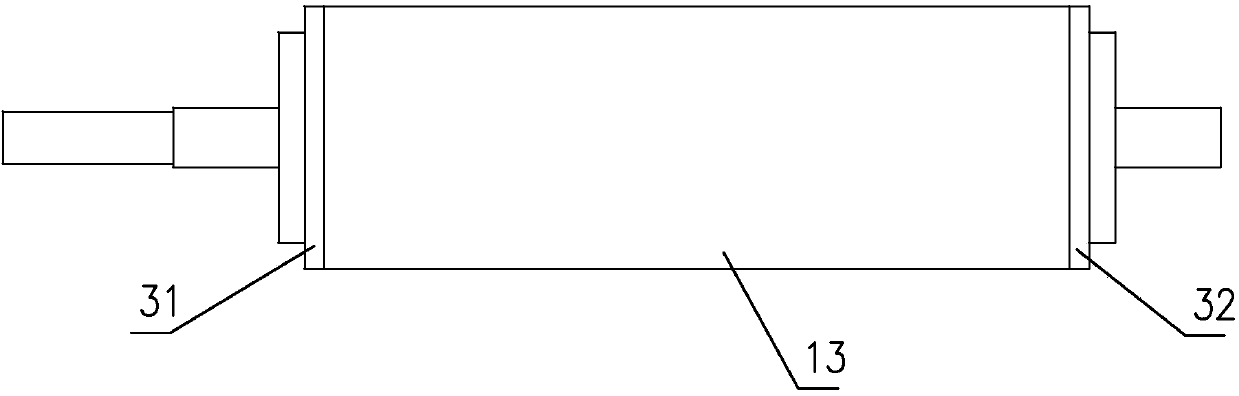

[0046] Such as Figure 1~3 As shown, it is a dis...

Embodiment 2

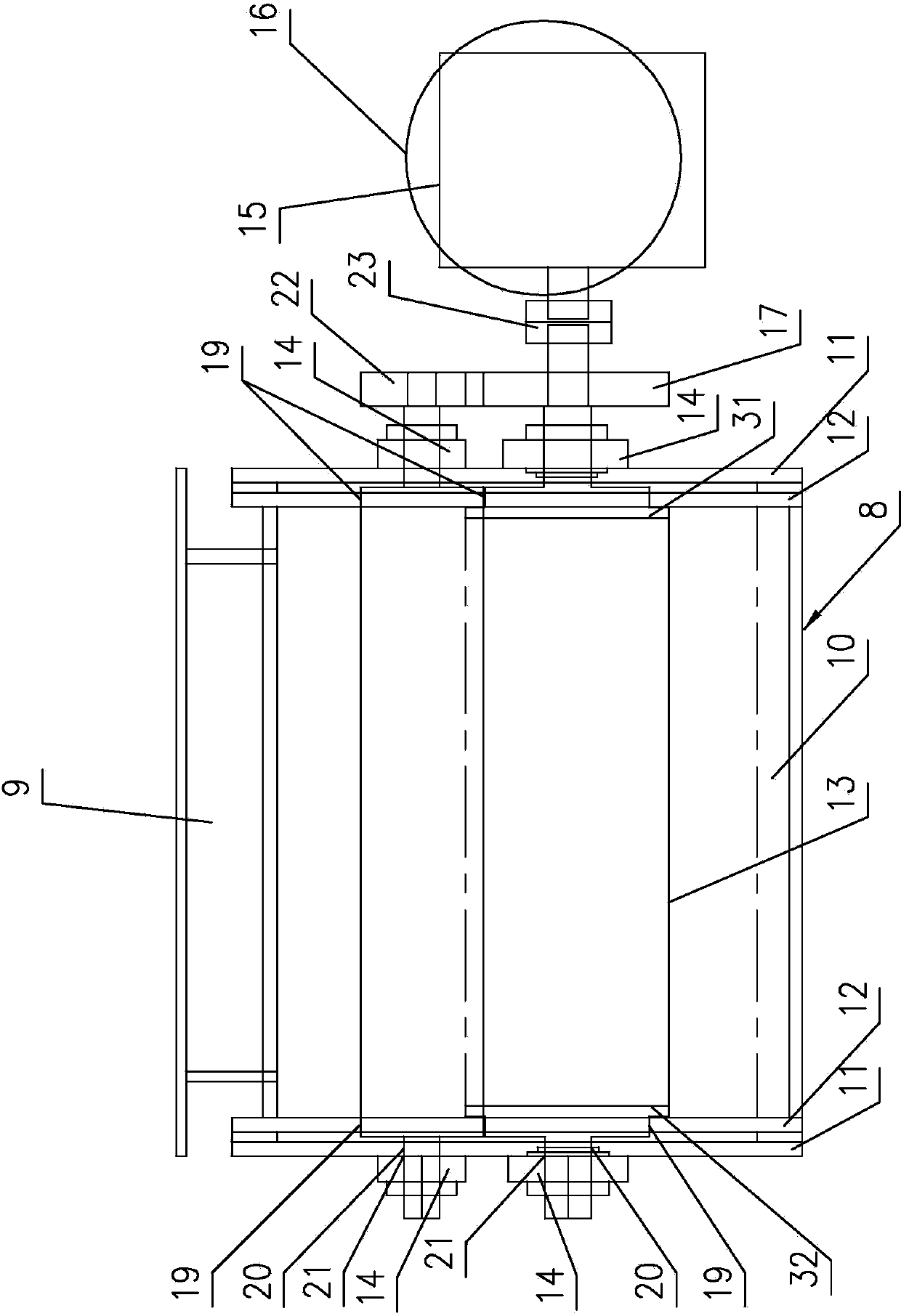

[0054] Such as Figure 4 , 5 As shown, the difference between this embodiment and Embodiment 1 is that a pair of pressing devices are installed on one of the closely attached rollers, and the material squeezes the rollers so that the rollers move outwards through the pressing devices to form a discharge space To ensure that the material is squeezed out from the discharge space. After the material is discharged, the pressing device will press the squeezed roller back to the tight state to ensure no air leakage. The pair of pressing devices are respectively arranged on both sides of the outer end of the outer plate of the casing. The pressing device includes two parallel support slide rails 41 fixed on the outer plate, and a T that is slidably installed on the two support slide rails. Type bearing 42, slide bar 43, spring pressing plate 41a and compression spring 44, and spring pressing plate 41a is fixed on the end of support slide rail 41, and the axle head of wherein a cyli...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 2 is that no lagging is provided on the drum, and the discharge space is only formed by the space released by the material pressing the drum to move the drum outward. Specifically, it is realized by the pressing device in Embodiment 2, and the structure of the pressing device will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com