Refining method of aloe polysaccharide having high content and high purity

The technology of aloe polysaccharide and refining method, which is applied in the field of plant processing, can solve problems such as low polysaccharide content, and achieve the effects of high polysaccharide purity, high explosion-proof safety requirements, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

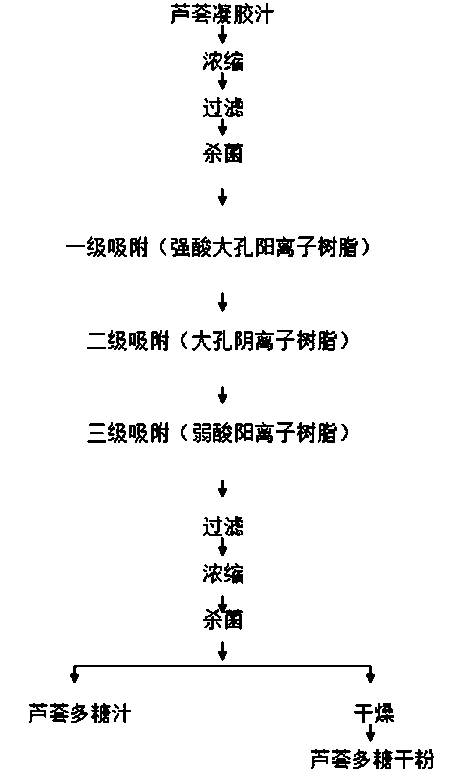

Method used

Image

Examples

Embodiment 1

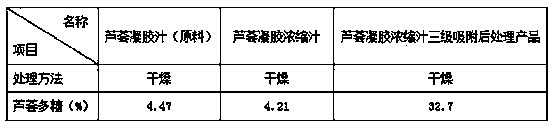

[0022] A. The raw material of aloe gel juice is obtained by cleaning, disinfecting, cleaning, squeezing and filtering the aloe leaves, and concentrates 40 tons of aloe gel juice raw materials (0.75% soluble solids, and 4.47% mass ratio of aloe polysaccharides) Until its soluble solids are 19%, then filter and sterilize to obtain 1.5 tons of concentrated aloe gel juice (the detection of aloe polysaccharide is 4.21% mass ratio);

[0023] B. According to the volume ratio of aloe gel concentrated juice: strong acid macroporous cation exchange resin=1.5:1, the aloe gel concentrated juice obtained in step A is passed through a commercially available industrial grade strong acid macroporous cation exchange resin column, and the contact time is controlled to be 25min , to obtain the aloe vera gel juice Ⅰ without protein and amino acid;

[0024] C. According to the volume ratio of aloe gel juice I: macroporous anion exchange resin=1:1, the aloe gel juice I obtained in step B is passed ...

Embodiment 2

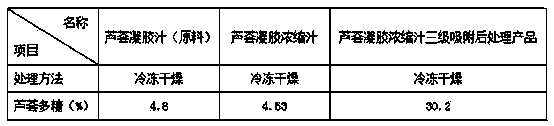

[0030] A. Obtain the aloe gel juice raw material by cleaning, disinfecting, cleaning, squeezing, and filtering the aloe leaves, and concentrate 25 tons of the aloe gel juice raw material (the soluble solids are 1.0%, and the detected aloe polysaccharide is 4.8% mass ratio) to The soluble solid content is 20%, and then filtered and sterilized to obtain 1.2 tons of concentrated aloe gel juice (the detection of aloe polysaccharide is 4.53% by mass);

[0031] B. According to the volume ratio of aloe gel concentrated juice: strong acid macroporous cation exchange resin=1:1, the aloe gel concentrated juice obtained in step A is passed through a commercially available industrial grade strong acid macroporous cation exchange resin column, and the control contact time is 25min , to obtain the aloe vera gel juice Ⅰ without protein and amino acid;

[0032] C, according to the volume ratio of aloe gel juice I: macroporous anion exchange resin=1.5:1, the aloe gel juice I obtained in step B...

Embodiment 3

[0038] A. The raw material of aloe gel juice (0.5% soluble solid content) is obtained by cleaning, disinfecting, cleaning, squeezing, and filtering the aloe vera leaves, and the raw material of aloe gel juice is concentrated to 18% of its soluble solid content, and then filtered , sterilizing and preparing concentrated aloe gel juice;

[0039] B. According to the volume ratio of aloe gel concentrated juice: strong acid macroporous cation exchange resin=5:1, the aloe gel concentrated juice obtained in step A is passed through a commercially available industrial grade strong acid macroporous cation exchange resin column, and the contact time is controlled to be 20min , to obtain the aloe vera gel juice Ⅰ without protein and amino acid;

[0040] C. According to the volume ratio of aloe gel juice I: macroporous anion exchange resin=2:1, the aloe gel juice I obtained in step B is passed through a commercially available industrial grade macroporous anion exchange resin column, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com