Apatite-structure fluorescent powder capable of exciting blue green light and preparation method thereof

A technology of apatite and phosphor, applied in the field of phosphor with apatite structure and its preparation, can solve the problems of high color temperature, lack of red light, low light efficiency, etc., and achieve simple preparation method, no pollution to the environment, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

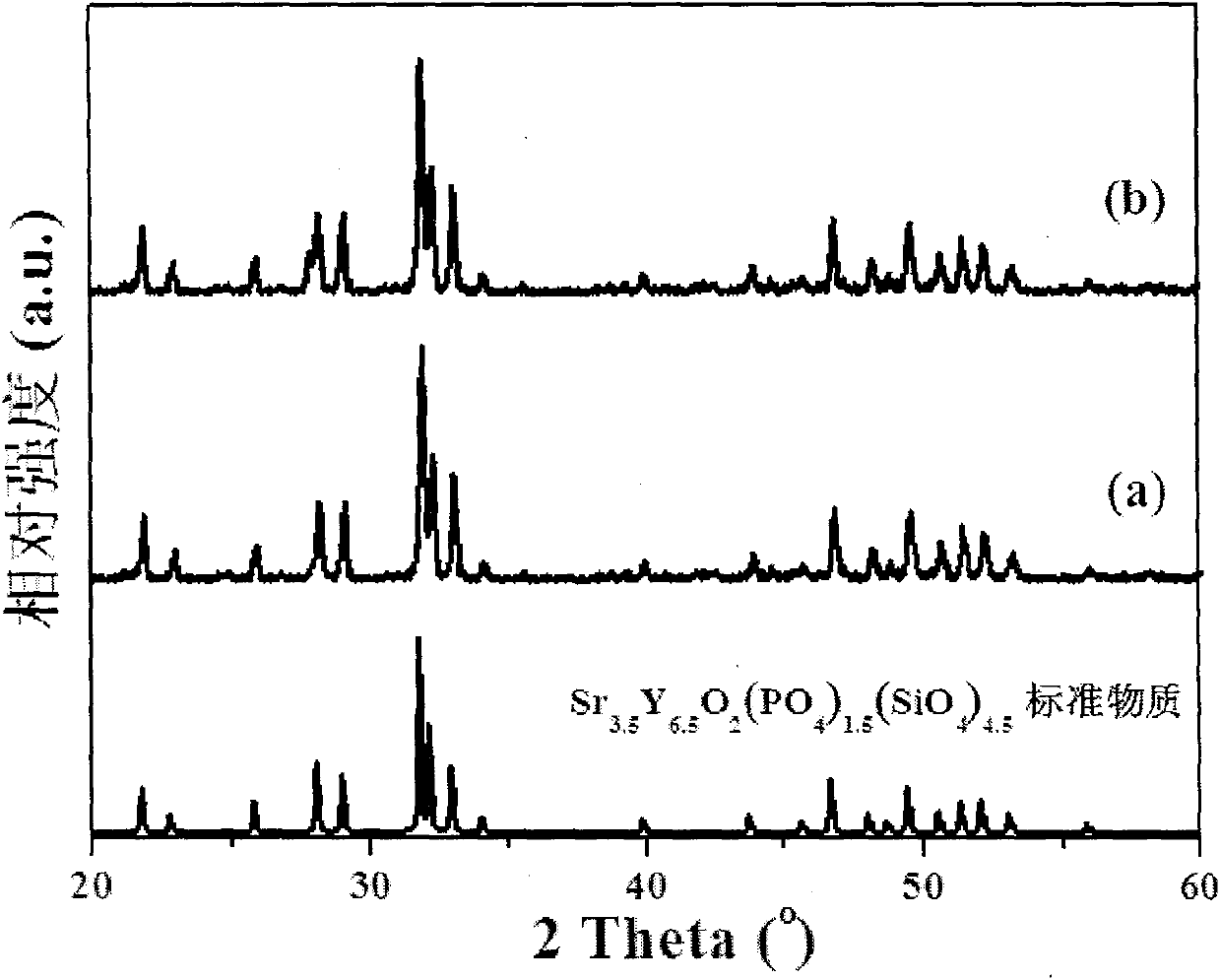

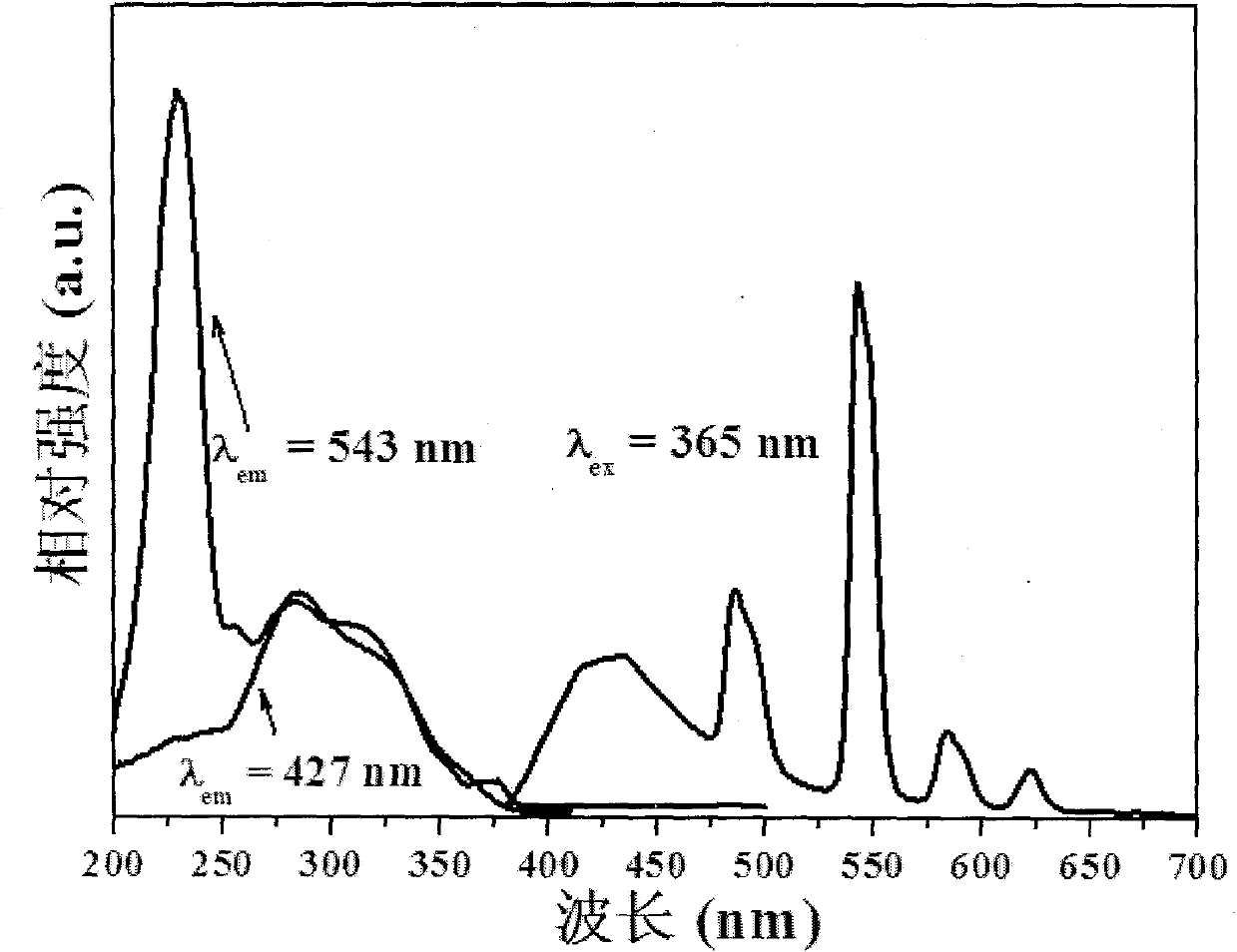

[0018] Embodiment 1: The material composition is Sr 3.5 Y 6.45 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+

[0019] Press Sr 3.5 Y 6.45 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ In the molar ratio of each element, accurately weigh 0.5gSrCO 3 , 0.7047g Y 2 o 3 , 0.1917g (NH 4 ) 2 HPO 4 , 0.2616g SiO 2 and 0.0083g CeO 2 High-purity powder raw materials are placed in an agate mortar and ground for about 30 minutes to fully mix the raw materials evenly. Transfer the mixed raw materials to the alumina crucible, add and nest the small corundum crucible in the large crucible with carbon powder, cover it and place it in a high-temperature reaction furnace for sintering at 1500°C for 5 hours, take it out after natural cooling, and grind again In about 15 minutes, a single-phase Sr 3.5 Y 6.45 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ Phosphor.

Embodiment 2

[0020] Embodiment 2: The material composition is Sr 3.5 Y 6.4 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ , 0.05Tb 3+

[0021] Press Sr 3.5 Y 6.4 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ , 0.05Tb 3+ In the molar ratio of each element, accurately weigh 0.5g SrCO 3 , 0.6992g Y 2 o 3 , 0.1917g (NH 4 ) 2 HPO 4 , 0.2616g Si0 2 , 0.0090g Tb 4 o 7 and 0.0083g CeO 2High-purity powder raw materials are placed in an agate mortar and ground for about 30 minutes to fully mix the raw materials evenly. Transfer the mixed raw materials to the alumina crucible, add and nest the small corundum crucible in the large crucible with carbon powder, cover it and place it in a high-temperature reaction furnace for sintering at 1500°C for 5 hours, take it out after natural cooling, and grind again In about 15 minutes, a single-phase Sr 3.5 Y 6.4 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ , 0.05Tb 3+ Phosphor.

Embodiment 3

[0022] Embodiment 3: The material composition is Sr 3.5 Y 6.3 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ , 0.15Tb 3+

[0023] Press Sr 3.5 Y 6.3 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ , 0.15Tb 3+ In the molar ratio of each element, accurately weigh 0.5g SrCO 3 , 0.6883g Y 2 o 3 , 0.1917g (NH 4 ) 2 HPO 4 , 0.2616g SiO 2 , 0.0271g Tb 4 o 7 and 0.0083g CeO 2 High-purity powder raw materials are placed in an agate mortar and ground for about 30 minutes to fully mix the raw materials evenly. Transfer the mixed raw materials to the alumina crucible, add and nest the small corundum crucible in the large crucible with carbon powder, cover it and place it in a high-temperature reaction furnace for sintering at 1500°C for 5 hours, take it out after natural cooling, and grind again In about 15 minutes, a single-phase Sr 3.5 Y 6.3 o 2 (PO 4 ) 1.5 (SiO 4 ) 4.5 : 0.05Ce 3+ , 0.15Tb 3+ Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com