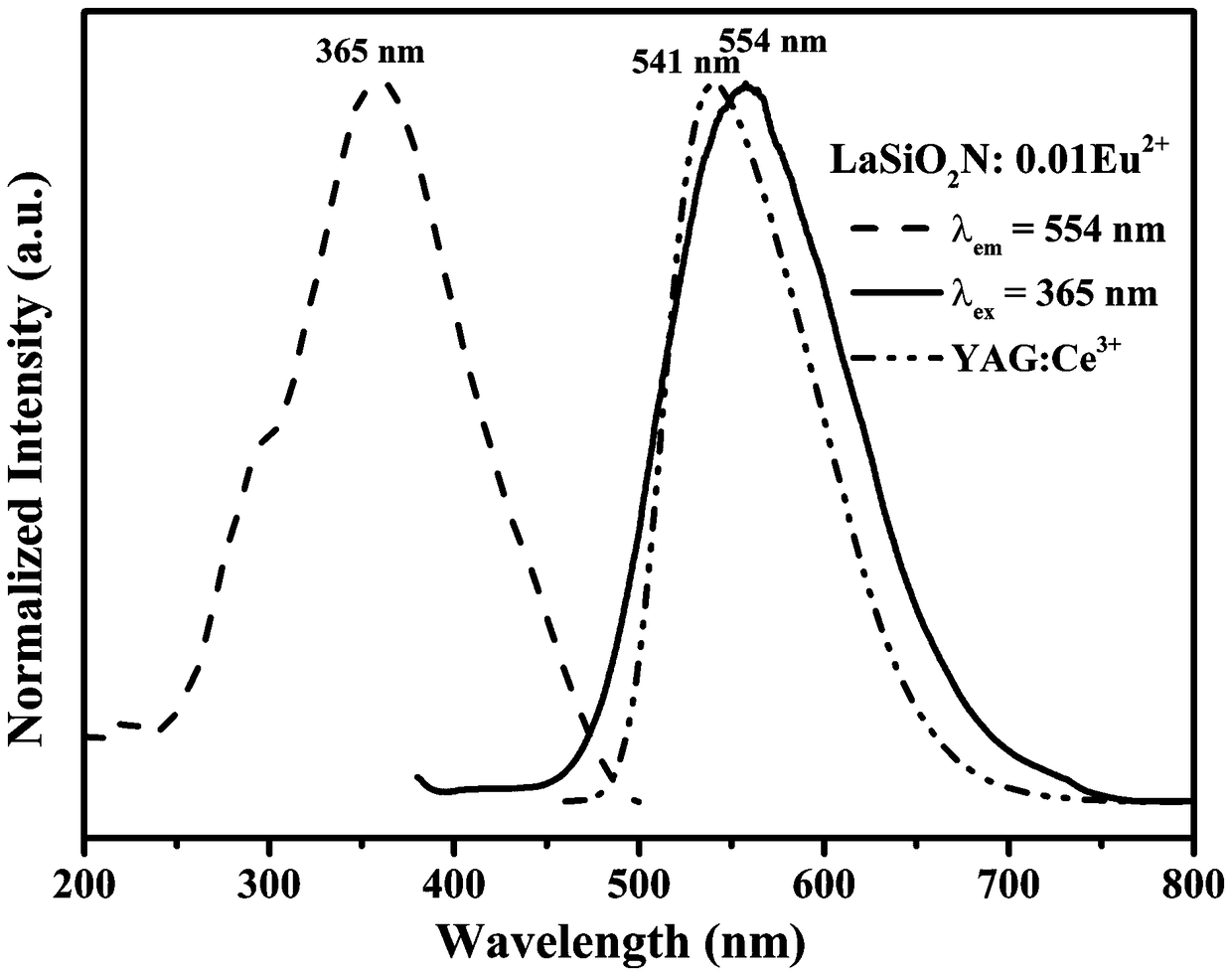

A kind of nitrogen oxide fluorescent material with yellow-orange light type wollastonite structure and preparation method thereof

A fluorescent material, wollastonite technology, applied in the fluorescent field, achieves excellent high temperature resistance, simple preparation method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Analytical pure La 2 o 3 、Si 3 N 4 、Eu 2 o 3 As a raw material, according to La 0.94 SiO 2 N:0.06Eu 2+ The molar ratio of each element in the formula, accurate ingredients, put it in an agate mortar and grind for about 30 minutes, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to an alumina crucible, nest a small corundum crucible in a large crucible with carbon powder, cover it and place it in an atmosphere furnace, and use a volume ratio of 10%:90% H 2 and N 2 The mixed gas is the reaction gas, keep the air pressure stable within the range of 0.1-2MPa, sinter at 1450°C for 12 hours, take it out after natural cooling, and grind again for about 15 minutes to obtain a single phase La 0.94 SiO 2 N:0.06Eu 2+ Phosphor.

Embodiment 2

[0022] Analytical pure La 2 o 3 、Si 3 N 4 、Eu 2 o 3 As a raw material, according to La 0.94 SiO 2 N:0.06Eu 2+ The molar ratio of each element in the formula, accurate ingredients, put it in an agate mortar and grind for about 30 minutes, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to an alumina crucible, nest a small corundum crucible in a large crucible with carbon powder, cover it and place it in an atmosphere furnace, and use a volume ratio of 10%:90% H 2 and N 2 The mixed gas is the reaction gas, keep the air pressure stable in the range of 0.1-2MPa, sinter at 1500°C for 6 hours, take it out after natural cooling, and grind again for about 15 minutes to obtain a single-phase La 0.94 SiO 2 N:0.06Eu 2+ Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com