Low-rank coal alcoholysis deoxidization method

A low-rank coal, anhydrous ethanol technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of reaching 20.71%, harsh process conditions, low total coal oxygen removal rate, etc., to reduce production costs, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Low-order coal alcohol solution deoxygenation method of the present invention, its preferred embodiment is:

[0020] Include steps:

[0021] A. Weigh 1 part by weight of dry-based low-rank coal and 3 to 10 parts by weight of absolute ethanol, mix them uniformly and pour them into an autoclave;

[0022] B. Fill the sealed autoclave with N with a purity greater than 99% 2 The oxygen in the kettle is exhausted, the stirring speed in the high-pressure reactor is 300-400rad / min, the heating rate is controlled at 5-10°C / min to the reaction temperature of 220°C-300°C, and then the temperature is kept constant for 30min-120min;

[0023] C. Cool the high-pressure reactor to room temperature, take out the reaction product and vacuum filter to obtain filtrate and filter residue respectively, and obtain deoxidized coal after vacuum drying the obtained filter residue.

[0024] In described step B, use the N that purity is greater than 99% earlier 2 After purging for 3 to 5 times,...

Embodiment 1

[0033] Example 1, the process conditions are temperature (220°C or 300°C), constant temperature time (30min or 120min), and coal dissolving ratio (3:1 or 10:1).

[0034] In the first step, weigh 1 part by weight of low-rank coal (dry basis) and 3 or 10 parts by weight of absolute ethanol, mix them uniformly, and pour them into an autoclave;

[0035] The second step is to seal the autoclave and fill it with nitrogen with a purity greater than 99% to remove the oxygen in the autoclave. The stirring speed in the autoclave is (300-400) rad / min, and the heating rate is controlled to be (5-10) ℃ / Min to the reaction temperature (220°C or 300°C) and then keep the temperature for 30min or 120min;

[0036] In the third step, the high-pressure reactor is cooled to room temperature, and the reaction product is taken out for vacuum filtration to obtain filtrate and coal sample respectively, and the obtained filter residue is vacuum-dried to obtain deoxidized coal.

Embodiment 2

[0037] Example 2, the process conditions are temperature (220-300°C), constant temperature time (30-120min), and coal-dissolving ratio (3:1-10:1).

[0038] In the first step, weigh 1 part by weight of low-rank coal (dry basis) and 3-10 parts by weight of absolute ethanol, mix them uniformly and pour them into a high-pressure reactor;

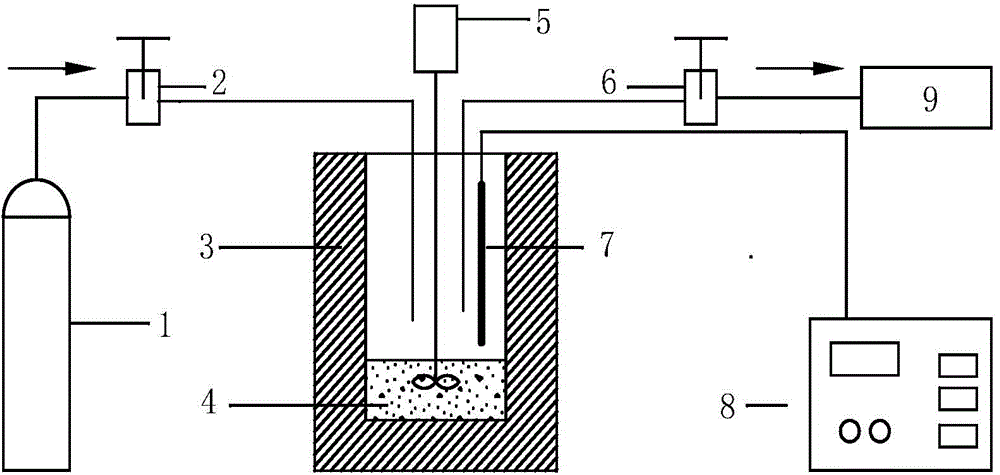

[0039] In the second step, the autoclave is sealed and filled with nitrogen with a purity greater than 99% ( figure 11) Exclude the oxygen in the kettle, the stirring speed in the high-pressure reactor is (300-400) rad / min, control the heating rate to be (5-10) °C / min to the reaction temperature (220-300 °C), and then keep the temperature for 30 minutes— 120min;

[0040] In the third step, the high-pressure reactor is cooled to room temperature, and the reaction product is taken out for vacuum filtration to obtain filtrate and coal sample respectively, and the obtained filter residue is vacuum-dried to obtain deoxidized coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com