Non-magnetic hard austenitic stainless steel for precision electron and manufacturing method thereof

A technology of austenitic stainless steel and precision electronics, which is applied in the field of nitrogen-containing nickel-saving stainless steel for precision electronics and its manufacturing field, can solve the problems of rising material cost, low Ni content and high Mn content, and achieve the effect of making up for adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

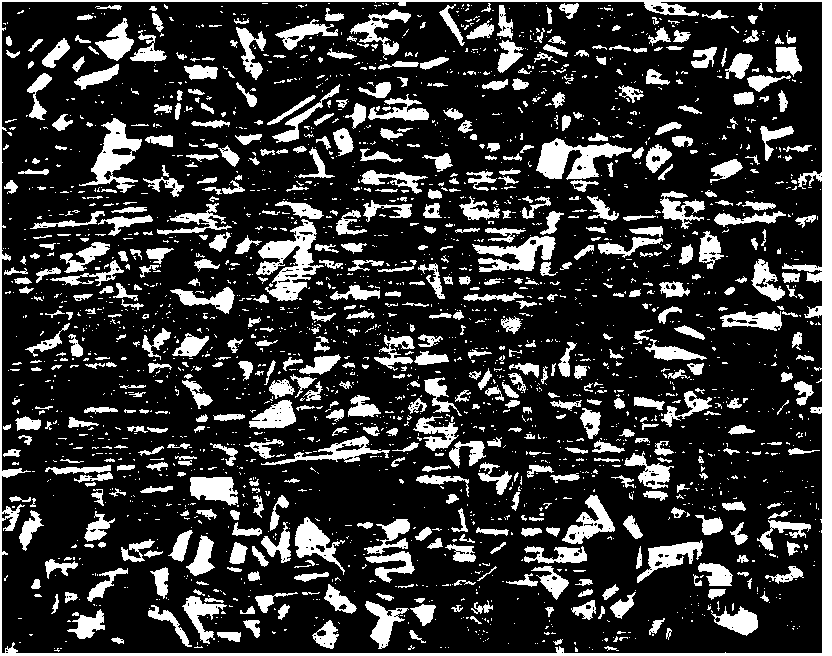

[0070] The alloy metallographic diagram of embodiment 2 is as figure 1 As shown (austenite structure at room temperature), the sample was electrolytically corroded, the etchant was saturated oxalic acid solution, and the corrosion current was 0.2-0.4A / cm 2 .

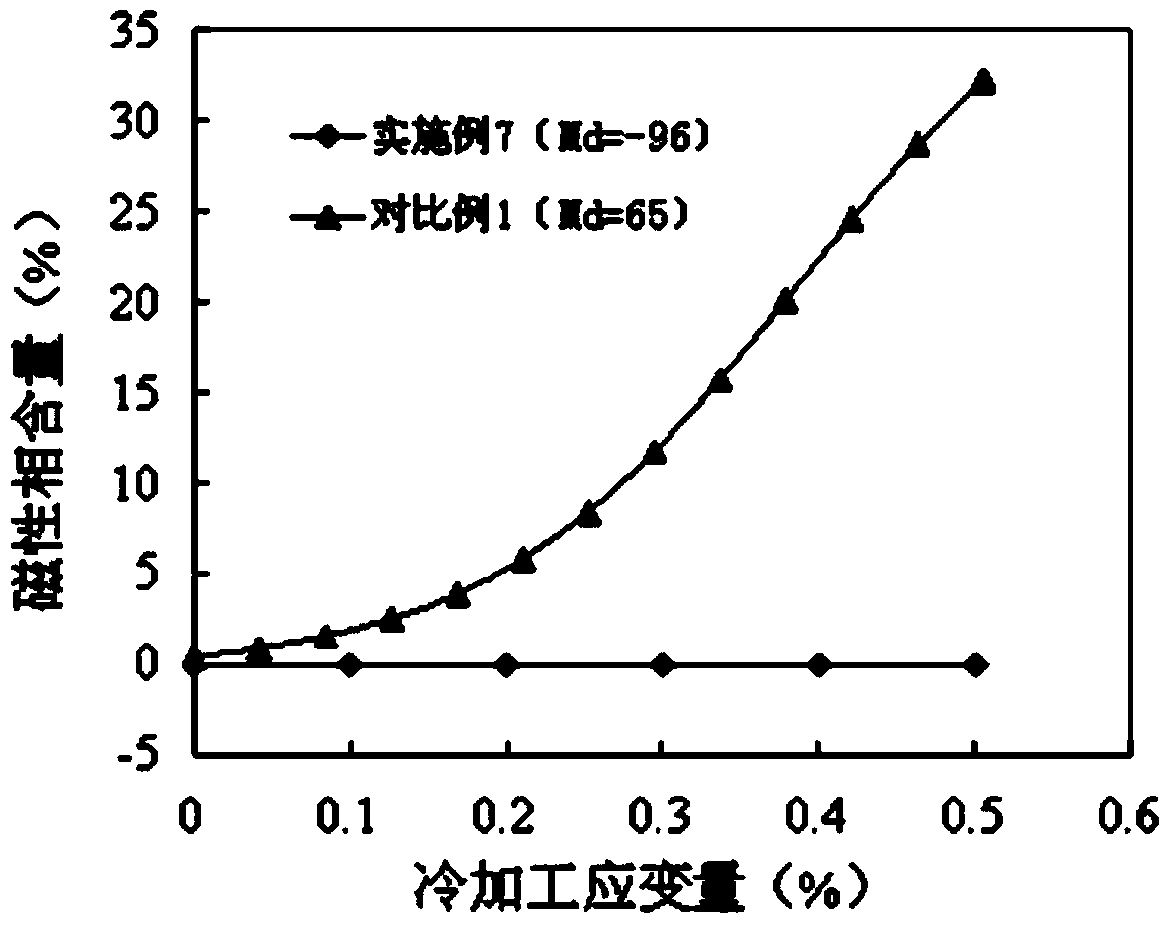

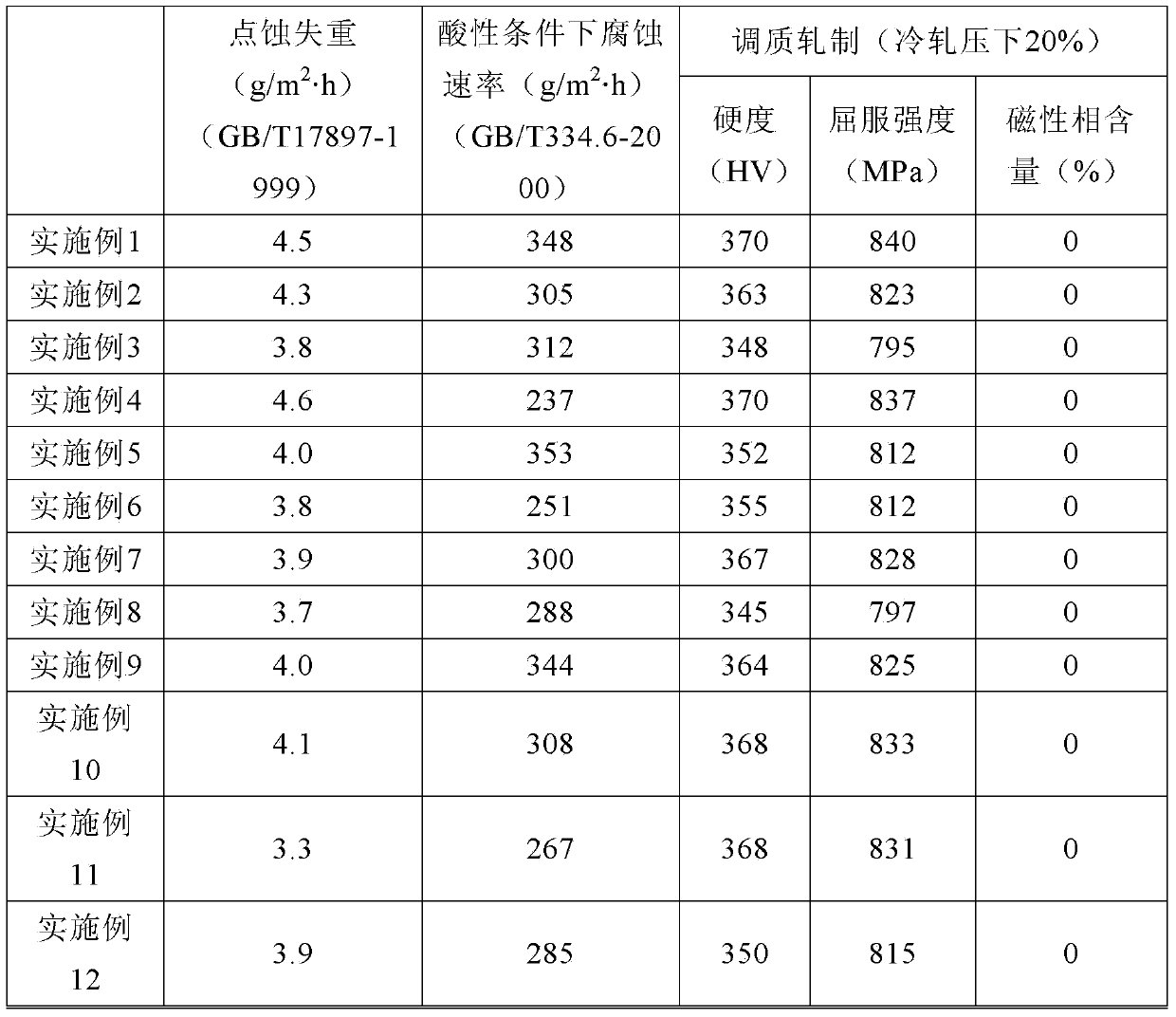

[0071] Table 1 shows the chemical composition of the steel of the embodiment of the present invention, the balance of which is Fe. Table 2 shows that steel M of the embodiment of the present invention d30 / 50 Temperature, chromium-nickel equivalent, pitting equivalent PREN, simulation value of acid corrosion resistance coefficient, etc.

[0072] Table 1 also shows the chemical composition of standard 304 austenitic stainless steel and Mn-N nickel-free austenitic stainless steel as comparative examples.

[0073] It can be seen from Table 2 and Table 3 that the pitting corrosion resistance equivalent and acid corrosion resistance coefficient of the traditional Fe-Cr-Mn-Ni-N series nickel-free austenitic stainless steel (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com