Slub yarn production control system

A technology for production control and slub yarn, applied in the direction of yarn, textile and paper making, etc., can solve the problems that it takes several minutes or even dozens of minutes, affects the utilization rate of the spinning frame, and the parameter setting is cumbersome, etc., to reduce the number of workers. Labor intensity, quick setup, and the effect of centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

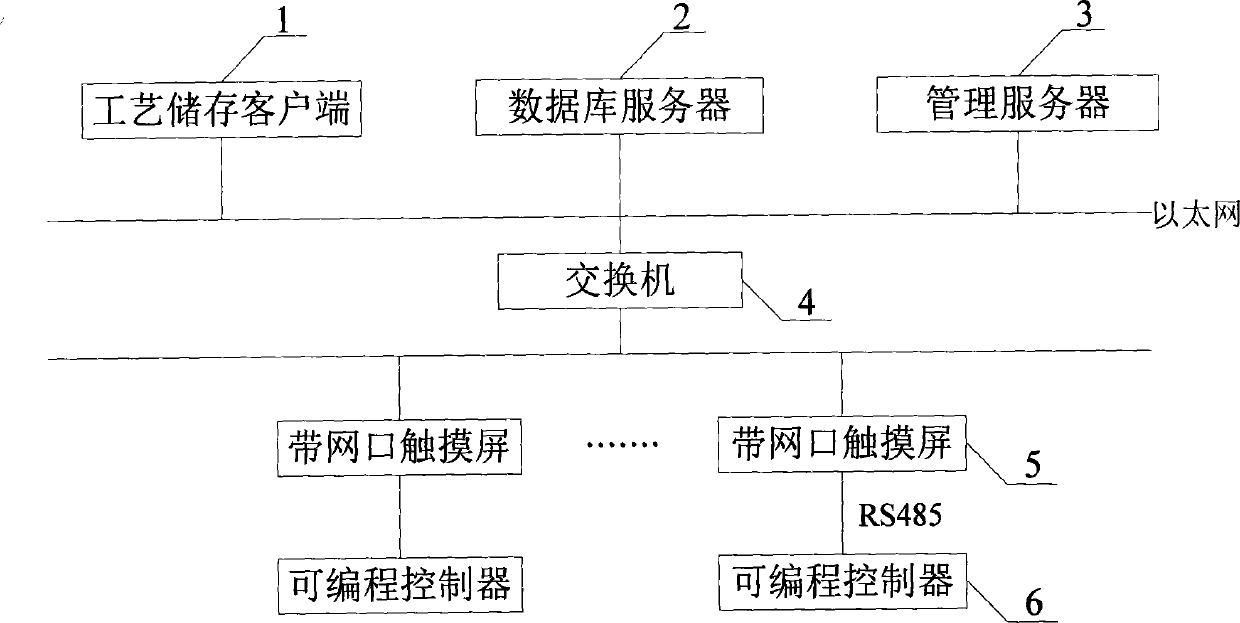

[0019] The slub yarn production control system consists of a process storage client 1, a database server 2, a management server 3, a switch 4, a touch screen 5 with an Ethernet port and a programmable controller 6.

[0020] The process storage client 1, the database server 2, the management server 3 and the touch screen 5 with an Ethernet port are all connected to the industrial Ethernet of the workshop through 4 pairs of shielded twisted-pair cables of super category 5, and the wiring length is 40 meters, exceeding 40 meters The industrial switch 4 is used to realize the expansion; the industrial switch supports IEEE802.3 / 802.3u / 802.3x standards, has an adaptive RJ45 interface, and adapts to a temperature range of -40 to 75°C to ensure that the temperature of the workshop can be normal Work.

[0021] The touch screen 5 with an Ethernet port also has a seria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com