Absorption compression type automatic-overlapping refrigerating system and use method

A refrigeration system, self-cascading technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of not being able to make more use of low-grade heat sources, greatly affecting system efficiency, and large irreversible losses, and achieve reduction High-grade energy consumption, expansion of utilization rate, and effect of increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

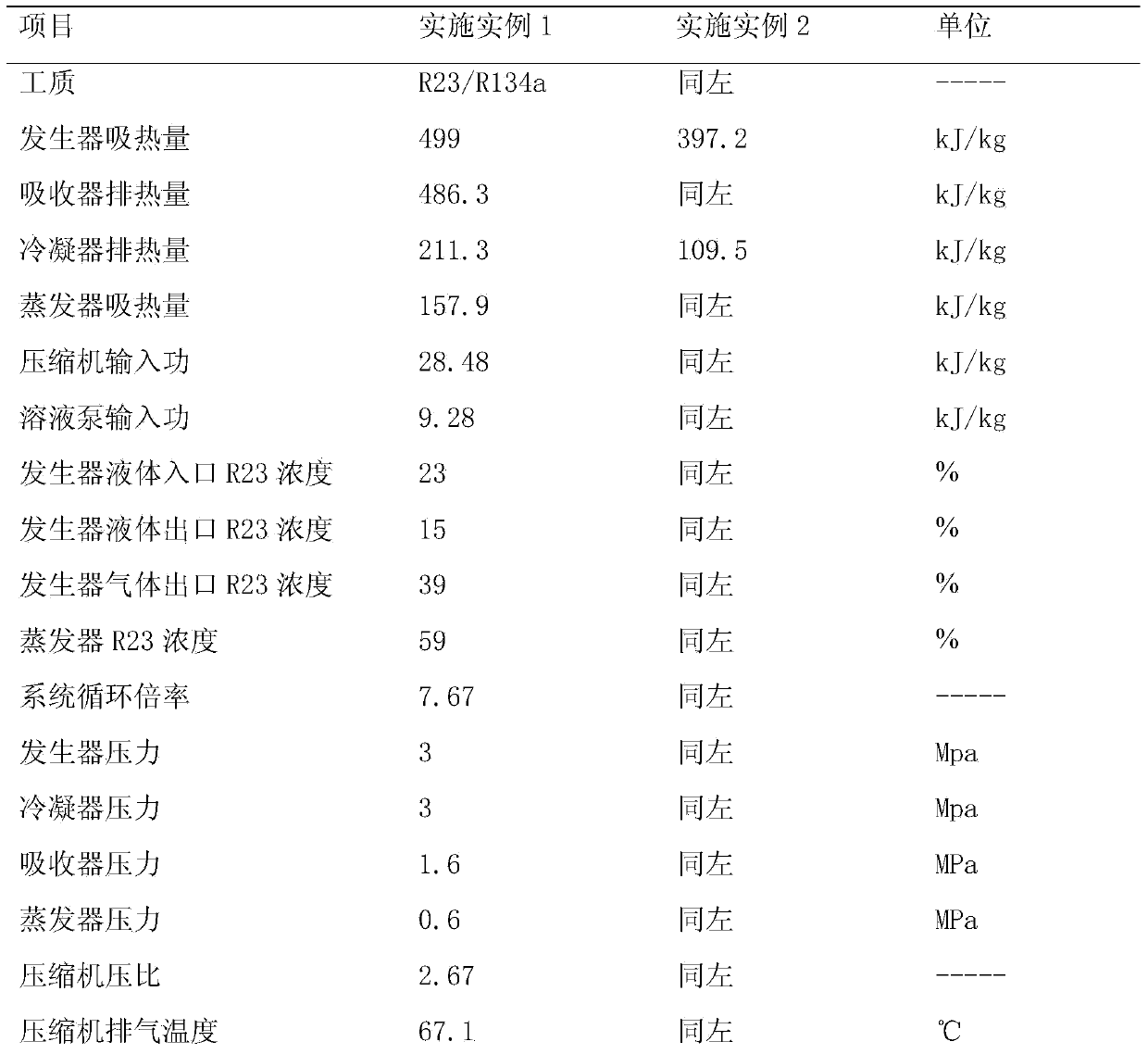

Embodiment 1

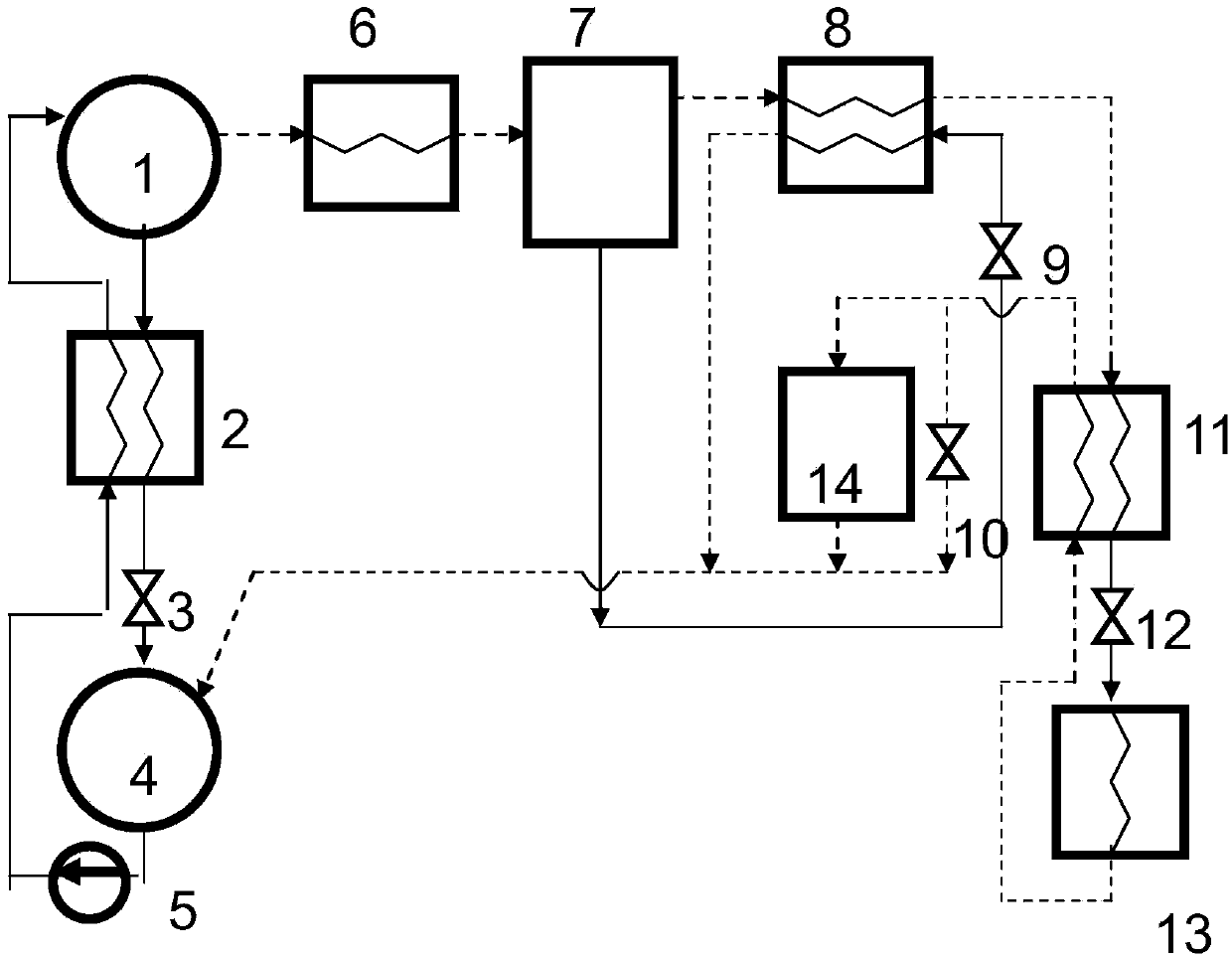

[0020] Implementation example 1, such as figure 1 An absorption-compression self-cascading refrigeration system is given, including a generator 1, a solution heat exchanger 2, an absorber 4, a solution pump 5, a condenser 6, a gas-liquid separator 7, an evaporative condenser 8, the first Gas-liquid heat exchanger 11, evaporator 13 and compressor 14.

[0021] The solution outlet of the generator 1 communicates with one end of the high-temperature solution pipeline of the solution heat exchanger 2, and the other end of the high-temperature solution pipeline of the solution heat exchanger 2 communicates with the solution inlet of the absorber 4; the high-temperature solution pipeline of the solution heat exchanger 2 A first throttle valve 3 is arranged between the solution pipeline port and the solution inlet of the absorber 4; the solution outlet of the absorber 4 communicates with one end of the low-temperature solution pipeline of the solution heat exchanger 2, and the low-tem...

Embodiment 2

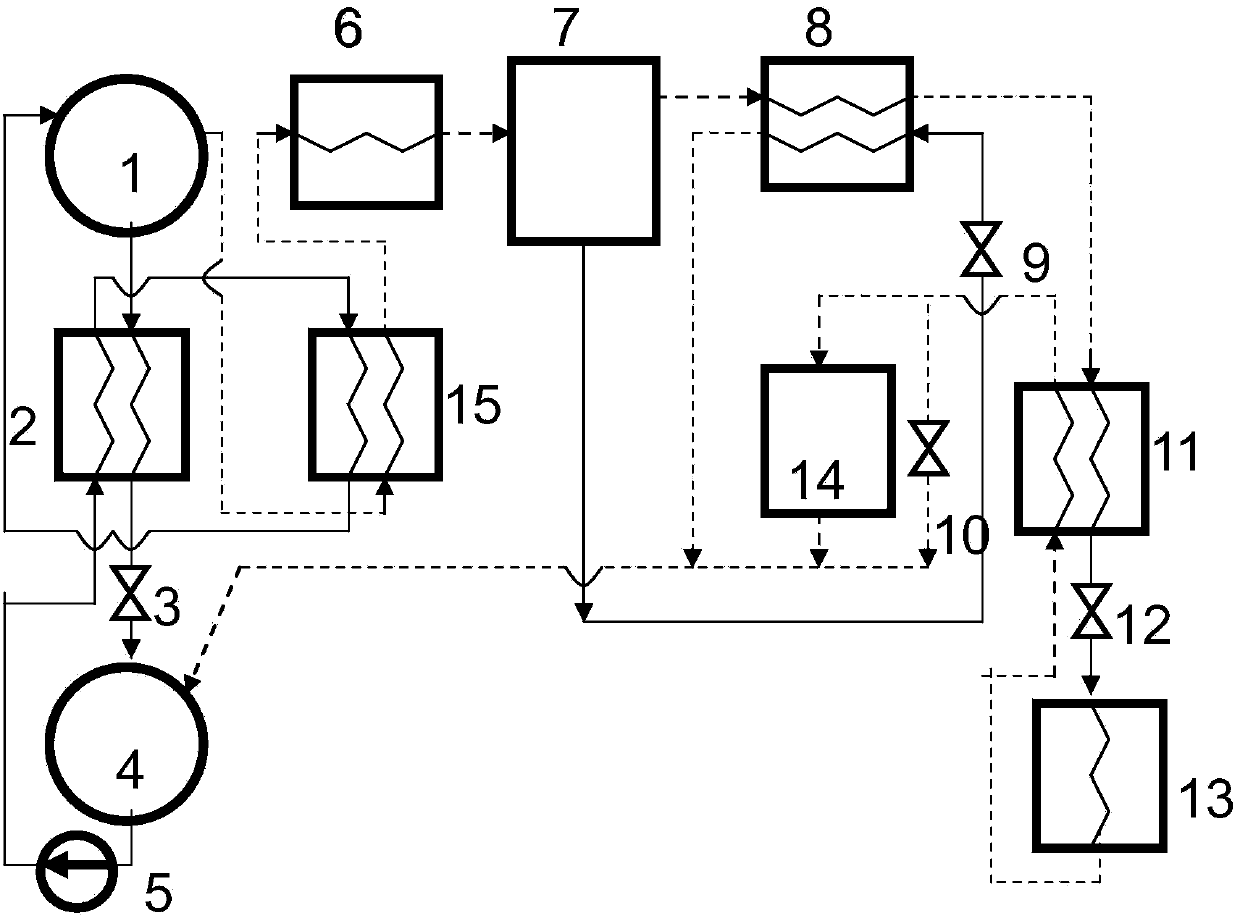

[0056] Implementation example 2, such as figure 2 , the system consists of generator 1, solution heat exchanger 2, first throttle valve 3, absorber 4, solution pump 5, condenser 6, gas-liquid separator 7, evaporative condenser 8, second throttle valve 9, The two-way valve 10, the first gas-liquid heat exchanger 11, the third throttle valve 12, the evaporator 13, the compressor 14 and the second gas-liquid heat exchanger 15 are composed.

[0057] In order to reduce the heat absorption of the generator and improve the COP of the system, in Embodiment 2, the absorption compression self-cascading refrigeration system of the present invention is adopted on the basis of the configuration of Embodiment 1, and the generator 1, the solution heat exchanger 2 and the condenser 6 are provided with a second gas-liquid heat exchanger 15: that is, the low-temperature solution pipeline of the solution heat exchanger 2 is connected to the low-temperature liquid pipeline of the second gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com