Heat pump air-conditioning system for electric automobile

A technology for heat pump air conditioners and electric vehicles, which is applied in high-efficiency regulation technology, lighting and heating equipment, climate sustainability, etc., can solve the problems of unreliable performance, complex system design, and high cost, and achieve reliable performance, compact system structure, and high cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

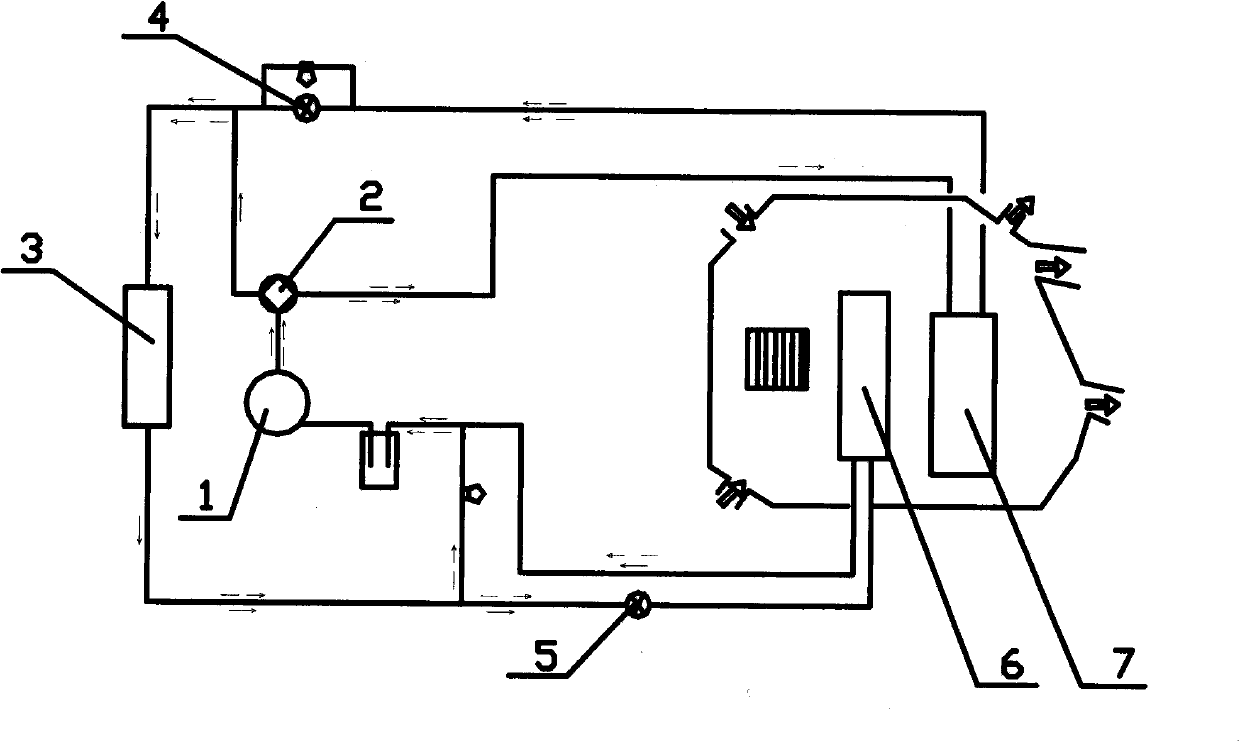

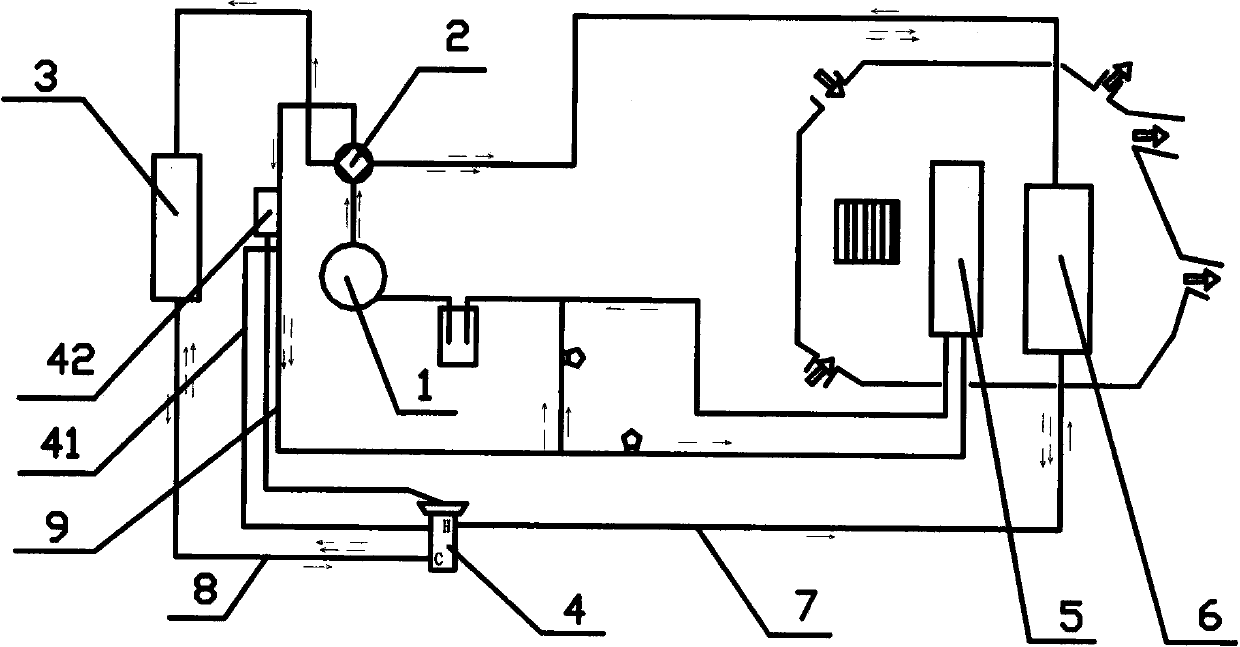

[0015] The present invention is mainly composed of a compressor 1, a four-way valve 2, an external heat exchanger 3, a two-way thermal expansion valve 4, an in-vehicle heat exchanger (A) 5, and an in-vehicle heat exchanger (B) 6. The expansion valve 4 is located between the external heat exchanger 3 and the internal heat exchanger (B) 6, the H interface of the two-way thermal expansion valve 4 is connected with the connecting pipe (A) 7, and the connecting pipe (A) 7 is connected with the vehicle The internal heat exchanger (B) 6 is connected, the C port of the two-way thermal expansion valve 4 is connected with the connecting pipe (B) 8, and the connecting pipe (B) 8 is connected with the external heat exchanger 3, and the two-way thermal expansion valve The outer balance pipe 41 communicates with the connecting pipe (C) 9 , and the temperature-sensing pipe 42 of the two-way thermal expansion valve contacts and binds with the connecting pipe (C) 9 .

[0016] It works as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com