Method for detecting content of micro-stickies in paper pulp

A detection method and sticky technology, which is applied in the field of papermaking, can solve the problems of lack of detection instruments and equipment, production process equipment and parameter scientific research obstacles, etc., and achieve the effect of convenient and fast detection method and direct and clear results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

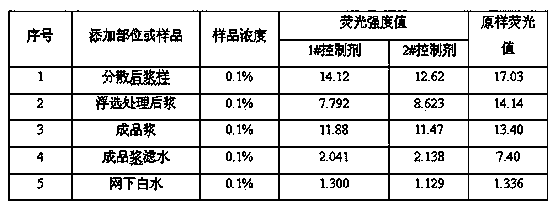

Embodiment 1

[0033] A method for detecting the content of fine stickies in pulp, comprising the following steps:

[0034] 1) Firstly, take pulp samples with different concentrations, add the first dispersion medium and stir, and prepare 500mL of suspensions with a mass fraction of 0.1% respectively, requiring uniform dispersion, and tap water is selected as the first dispersion medium;

[0035] 2) Then select the corresponding fluorescent dye, add distilled water and stir. In this experiment, Nile Red dye is selected to prepare a Nile Red dye solution with a mass fraction of 0.5%, and it is stored in a dark place at 5°C;

[0036] 3) When measuring, add 5 mL of the Nile Red dye solution prepared above to the 500 mL suspension in step 1); mix thoroughly for 10 minutes, and stir evenly to fully dye the lipid impurities in the pulp sample;

[0037] 4) Take the first dispersion medium, that is, tap water, and measure the fluorescence value, and use the measurement result as a blank value; respe...

Embodiment 2

[0040] A method for detecting the content of fine stickies in pulp, comprising the following steps:

[0041] 1) First, take pulp samples of different concentrations, add the first dispersion medium and stir, and prepare 500mL of suspensions with a mass fraction of 0.1% respectively. The first dispersion is required to be uniform, and tap water is selected as the first dispersion medium;

[0042] 2) Then select the corresponding fluorescent dye, add distilled water and stir. In this experiment, Nile Red dye is selected to prepare a Nile Red dye solution with a mass fraction of 0.5%, and it is stored in a dark place at 5°C;

[0043]3) During the measurement, add 10 mL of the above-prepared Nile Red dye solution to the 500 mL pulp fiber suspension in step 1); mix thoroughly for 10 minutes, and stir evenly to fully dye the lipid impurities in the pulp sample;

[0044] 4) Take the first dispersion medium, that is, tap water, and measure the fluorescence value, and use the measureme...

Embodiment 3

[0047] 1) First, take pulp samples with different concentrations, add the first dispersion medium and stir, and prepare 500mL of suspensions with a fraction of 0.5% respectively, requiring uniform dispersion, and tap water is selected as the dispersion medium;

[0048] 2) Then select the corresponding fluorescent dye, add distilled water and stir. In this experiment, Nile Red dye is selected to prepare a Nile Red dye solution with a mass fraction of 0.5%, and it is stored in a dark place at 5°C;

[0049] 3) During the measurement, add 15 mL of the above-prepared Nile Red dye solution to the 500 mL pulp fiber suspension in step 1); mix thoroughly for 10 minutes, and stir evenly to fully dye the lipid impurities in the pulp sample;

[0050] 4) Take the pulp dispersion medium, that is, tap water, and measure the fluorescence value, and the measurement result is used as a blank value; respectively take the uniformly mixed dyed pulp samples, and measure the fluorescence value; accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com