A Fault Detection Method for Stator Winding Asymmetry of Doubly-fed Wind Turbine Generator

A doubly-fed wind power generation and fault detection technology, applied in the direction of motor generator testing, etc., can solve the problems of large amount of calculation, easy to generate errors, high calculation accuracy requirements, etc., achieve strong anti-interference ability, simple implementation, and improve sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

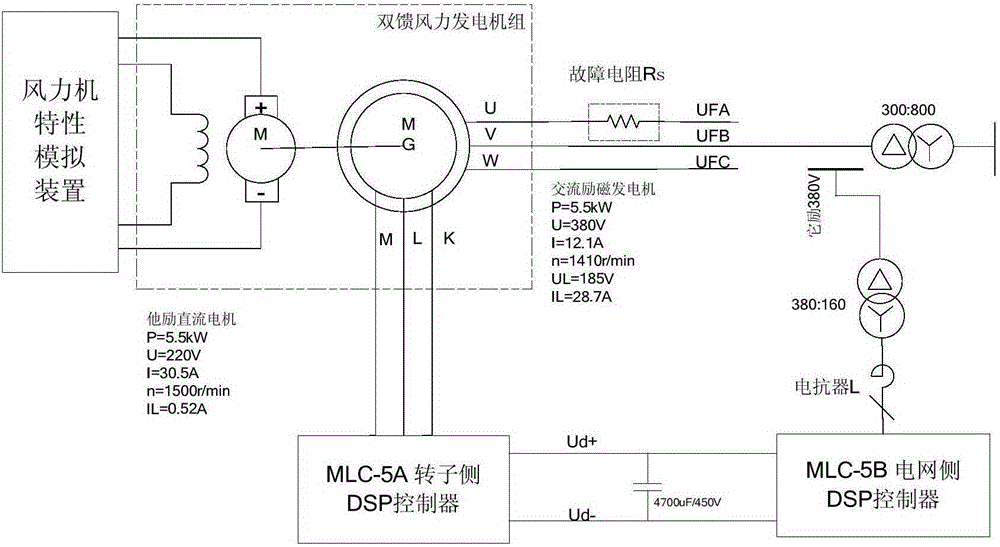

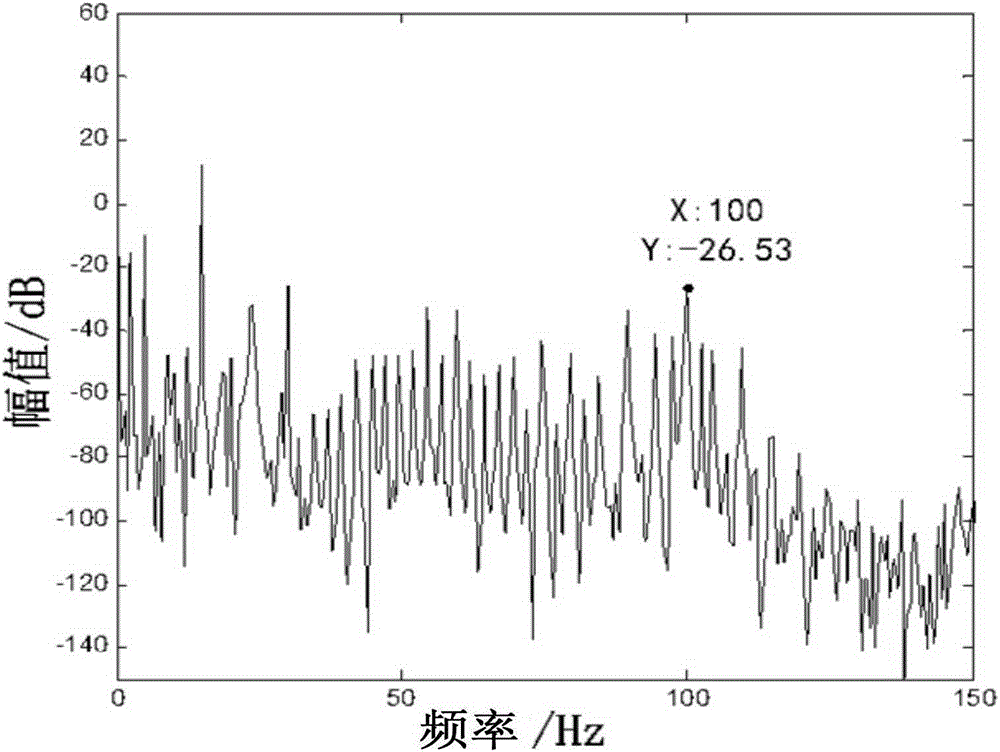

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

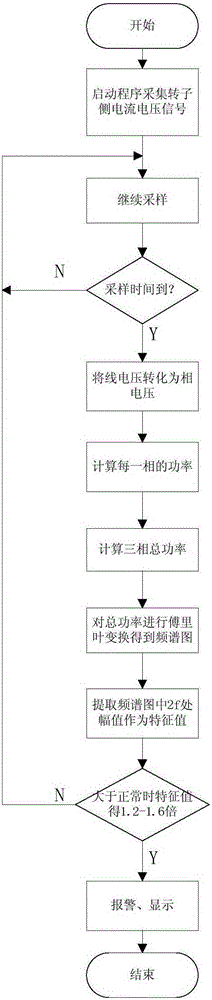

[0023] Such as figure 1 As shown, a doubly-fed wind turbine stator winding asymmetry fault detection method includes the following steps:

[0024] Step 1, through the current sensor and the voltage sensor on the rotor side of the doubly-fed wind turbine, respectively measure the rotor-side current and rotor-side voltage signals;

[0025] Step 2. Determine whether the sampling time has been reached. If the sampling time has not been reached, repeat step 1. Otherwise, perform step 3;

[0026] Step 3, converting the collected voltage signal from line voltage to phase voltage, and setting it as three phases a, b, and c;

[0027] Step 4. Multiply the current and voltage signals of each phase to obtain the power signal of each phase. Take phase A as an example:

[0028] p a = u a × i a (1)

[0029] Among them, u a is the instantaneous value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com