Laser direct-writing system and photolithography method

A technology of laser direct writing and exposure system, which is applied in the field of laser lithography, can solve problems such as inability to meet high-speed writing, and achieve the effects of fast focusing response speed, small mechanism adjustment amount, and fast focusing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

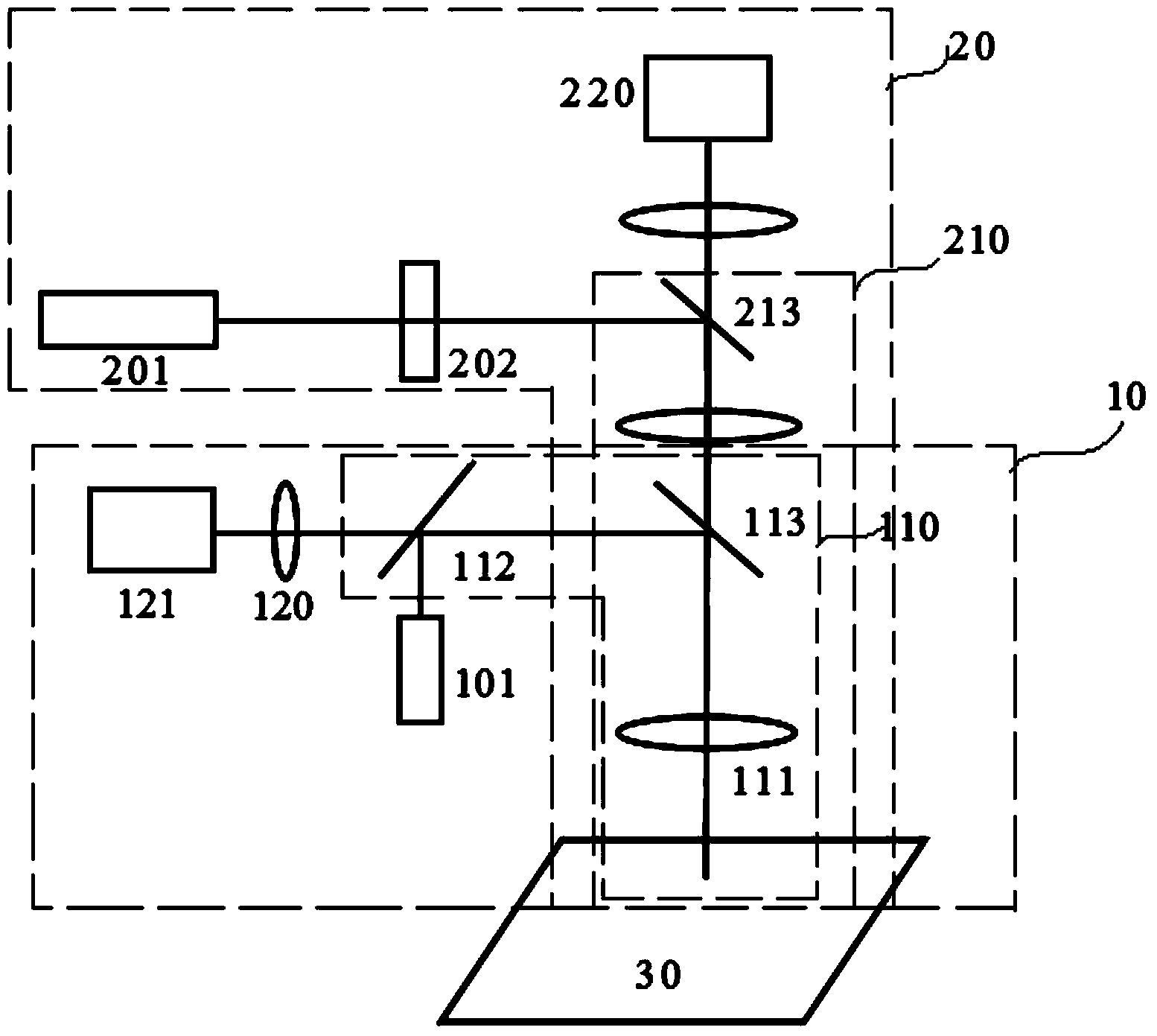

[0068] Compared with the first embodiment, in the second embodiment, the measurement optical path 110' only needs to consider the distribution of the two beams of incident light and reflected light, so the setting of optical lenses in the optical path can be saved. As shown in the figure, it can Only one half mirror 112' is used.

[0069] The exposure system 20' also includes a second light source 201', a pattern generator 202' and an exposure light path 210'. The incident light emitted by the second light source 201' passes through the pattern generator 202', the exposure light path 210', and is incident from the exposure objective lens 211. To form an exposure pattern on the surface of the object to be engraved.

[0070] In this second embodiment, the central controller used to control the mechanical movement of each component can be the same, such as Figure 4 As shown in , it is also possible to separately set up a central controller separately, and then exchange data bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com