A single-turn inductive pulse transformer

A pulse transformer and inductive technology, applied in the direction of magnetic bias transformer, transformer/inductor shell, transformer/inductor magnetic core, etc., can solve the problem of large impact of pulse waveform front, back edge, top drop, power transmission efficiency Low cost, high manufacturing cost and other issues, to achieve the effect of small size, high power transmission efficiency and low insulation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

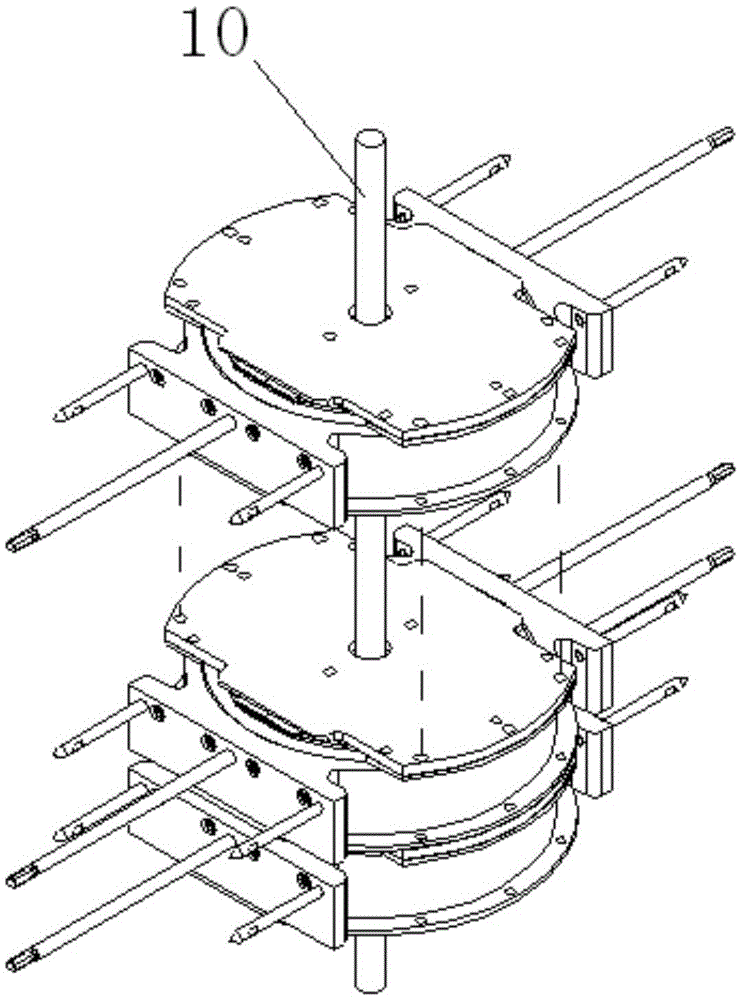

[0021] The invention is applied to the high-power modulator system adopting the induction superposition type. Through the series superposition of multiple groups, the principle of electromagnetic induction is used to couple and superimpose the low-voltage pulses and convert them into high-voltage pulses. Since the primary of the superimposed single-turn induction pulse transformer is at a lower potential, no strong insulation requirements need to be considered.

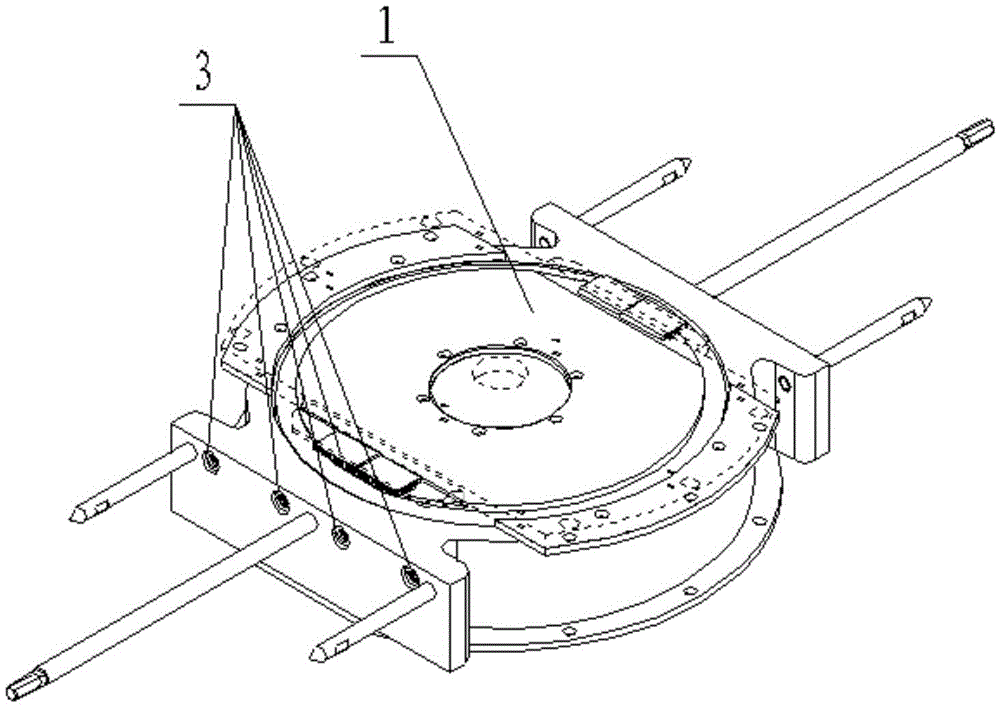

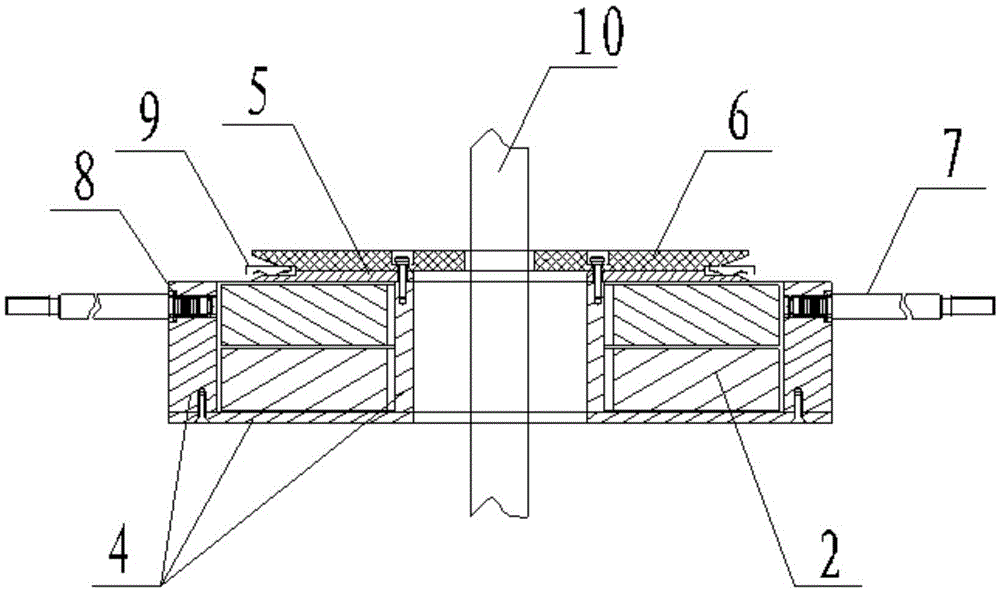

[0022] The present invention consists of a housing 1 as a single-turn primary coil, a ring core 2 and a connector 3 . The non-closed casing 1 is used as a single-turn primary coil. The housing 1 is composed of a base 4 as the low end of the single-turn primary coil, a copper plate 5 as the high end of the single-turn primary coil, an insulating plate 6 and a screw 7 for installing the primary power module. The inner cavity of the base 4 is used for installing the annular iron core 2, and a threaded hole is left on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com