Side-illuminated pin photodetector chip and manufacturing method thereof

A photodetector and manufacturing method technology, applied in the field of optical communication transmission, can solve the problems of large chip capacitance and distribution parameters, long drift time, butt coupling of passive optical waveguides, etc., achieve good butt coupling, reduce distribution parameters, ensure The effect of side light mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

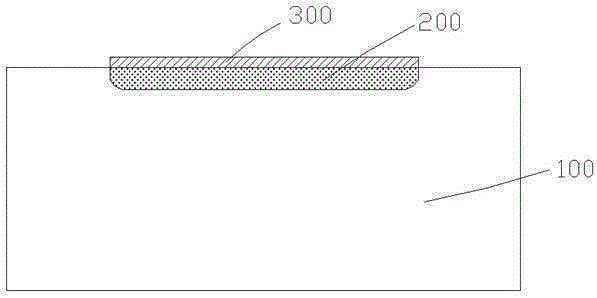

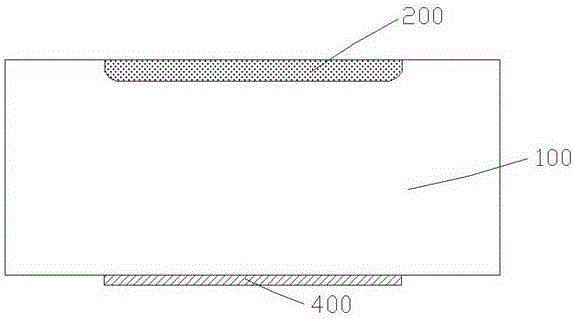

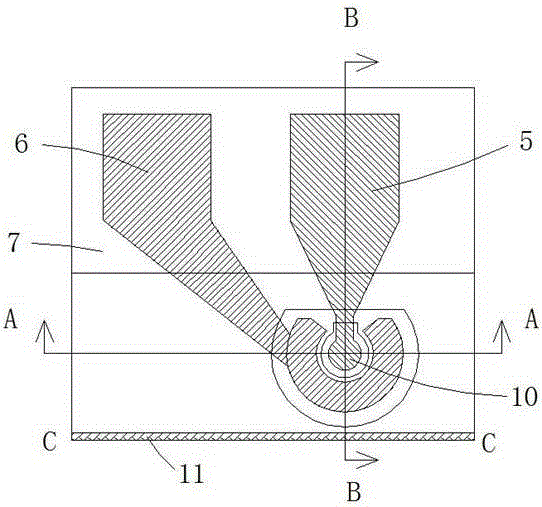

[0040] see Figure 3 to Figure 12 , the present invention provides a side-illuminated PIN photodetector chip, comprising: a substrate 12, a buffer layer 13 formed on the substrate 12, an absorbing layer 14 formed on the buffer layer 13, formed on The transition layer 15 on the absorption layer 14, the top layer 16 formed on the transition layer 15, the contact layer 17 formed on the top layer 16, the substrate 12, the buffer layer 13 and the contact layer 17 The composite passivation layer 19 on the composite passivation layer 19, the first protection layer 7 formed on the composite passivation layer 19, the negative electrode 6 formed on the first protection layer 7, the composite passivation layer 19 and the buffer layer 13, The positive electrode 5 formed on the contact layer 17, the composite passivation layer 19 and the first protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com